Suspended bed external separation system and using method thereof

A technology of separation system and suspension bed, which is applied in the field of external separation system of suspension bed, can solve the problems of short service life of catalyst, increase of production cost, clogging of catalyst pores, etc., so as to increase the operation cycle of the device, reduce production and operation cost, and ensure the use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

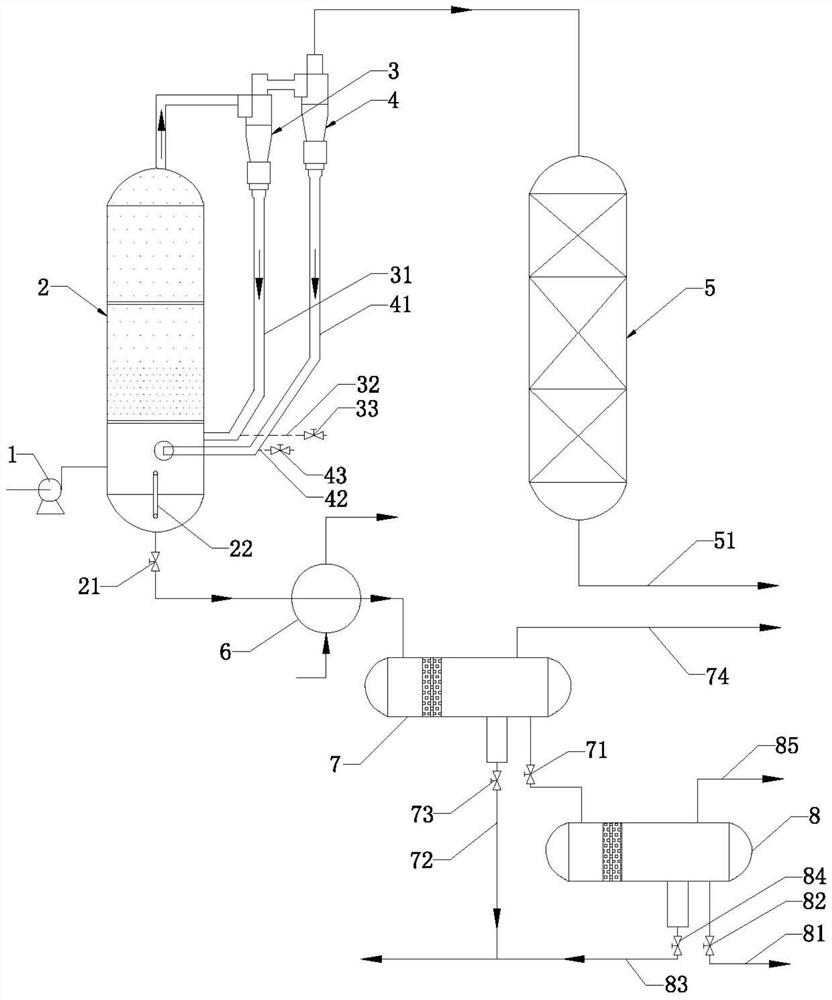

[0028] See figure 1 , an external separation system for a suspended bed, comprising a high-pressure feed pump 1, a suspended bed reactor 2, a primary cyclone separator 3, a secondary cyclone separator 4, a fixed bed reactor 5, a heat exchanger 6, and a cold high-pressure separation Device 7 and cold low-pressure separator 8;

[0029] The outlet of the high-pressure feed pump 1 is connected with the bottom inlet of the suspension bed reactor 2, the bottom of the primary cyclone separator 3 is connected with the first material leg 31, and the bottom of the secondary cyclone separator 4 is connected with the second material leg 41, The ends of the first material leg 31 and the second material leg 41 are respectively connected with the bottom inlet of the suspended bed reactor 2, the top inlet of the primary cyclone separator 3 is connected with the top outlet of the suspended bed reactor 2, and the primary cyclone separator The top outlet of 3 is connected with the top inlet of ...

Embodiment 2

[0039] A method for using the external separation system of a suspended bed, comprising the steps of:

[0040] The high-pressure feed pump 1 feeds from the middle and lower part of the bottom bed of the suspension bed reactor 2, mixes with the heavy components of the first material leg 31 and the second material leg 41, and with the hot air flow upwards, it is mixed with the catalyst in the suspension bed to react;

[0041] After the top product of the suspended bed reactor 2 is separated by the primary cyclone separator 3 and the secondary cyclone separator 4, the light components enter the fixed bed reactor 5 for further demetallization, denitrogenation and other reactions; and the first dipleg 31 1. The heavy components separated by the second dipleg 41 and oil products containing catalyst powder and heavy metals enter the suspended bed reactor 2 again to react with the raw materials;

[0042]The heavy component inside the suspended bed reactor 2 is deposited to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com