Radiation-sensitive compositions and imageable materials

A radiation-sensitive composition technology, applied in the field of radiation-sensitive compositions and imageable materials, can solve the problems of reducing photosensitive speed and operating cycle, reducing production yield, weak printing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

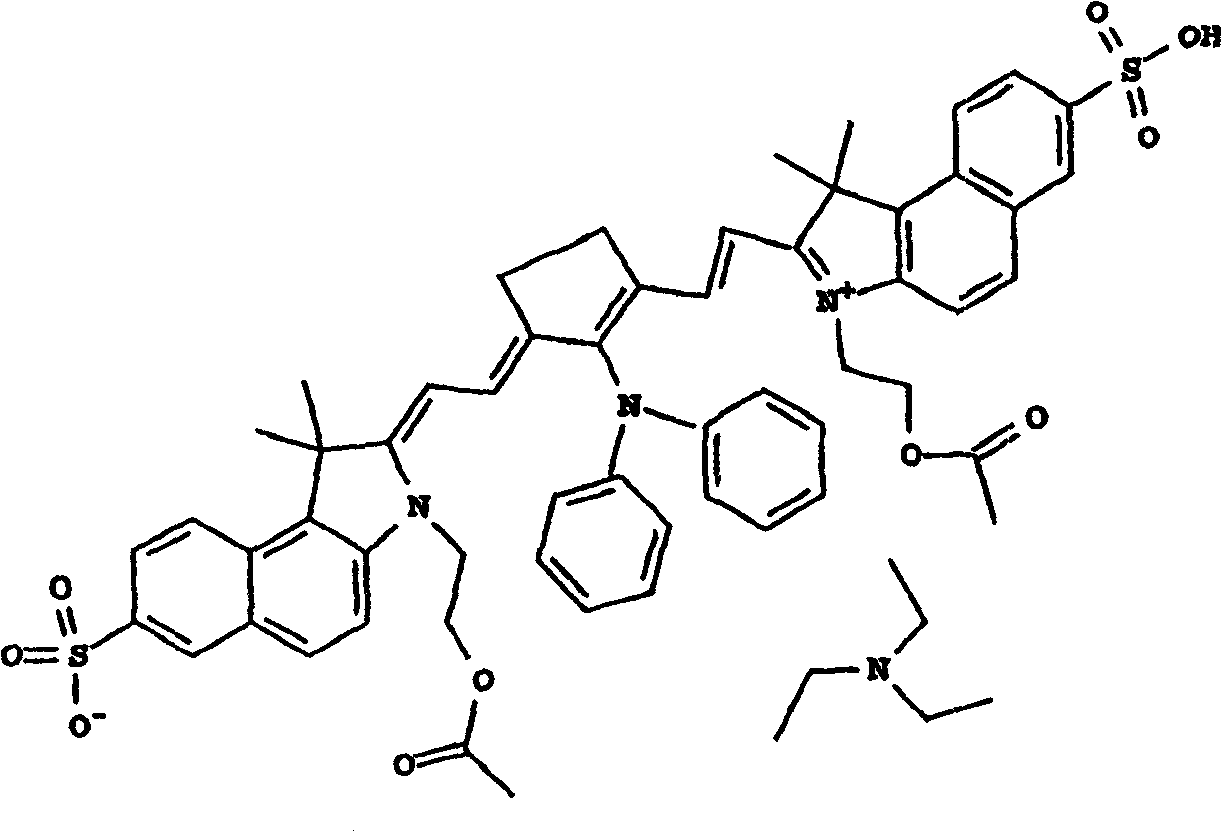

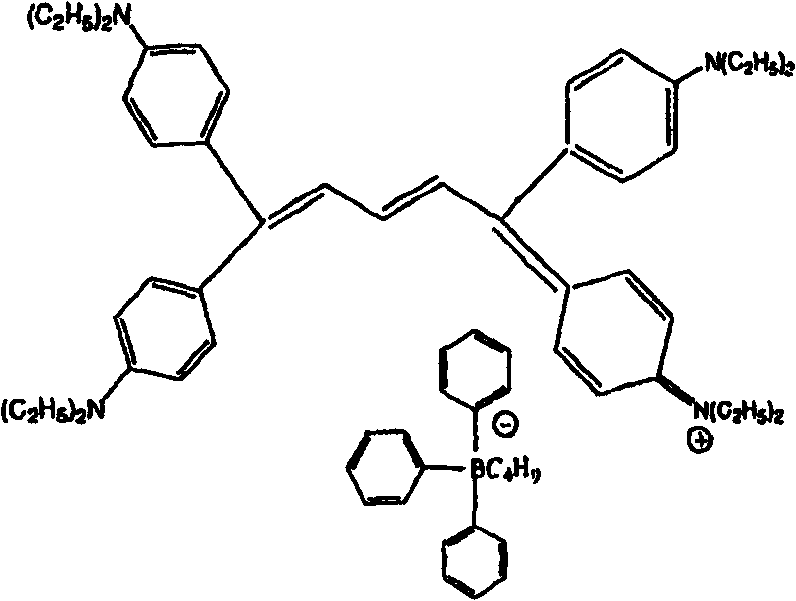

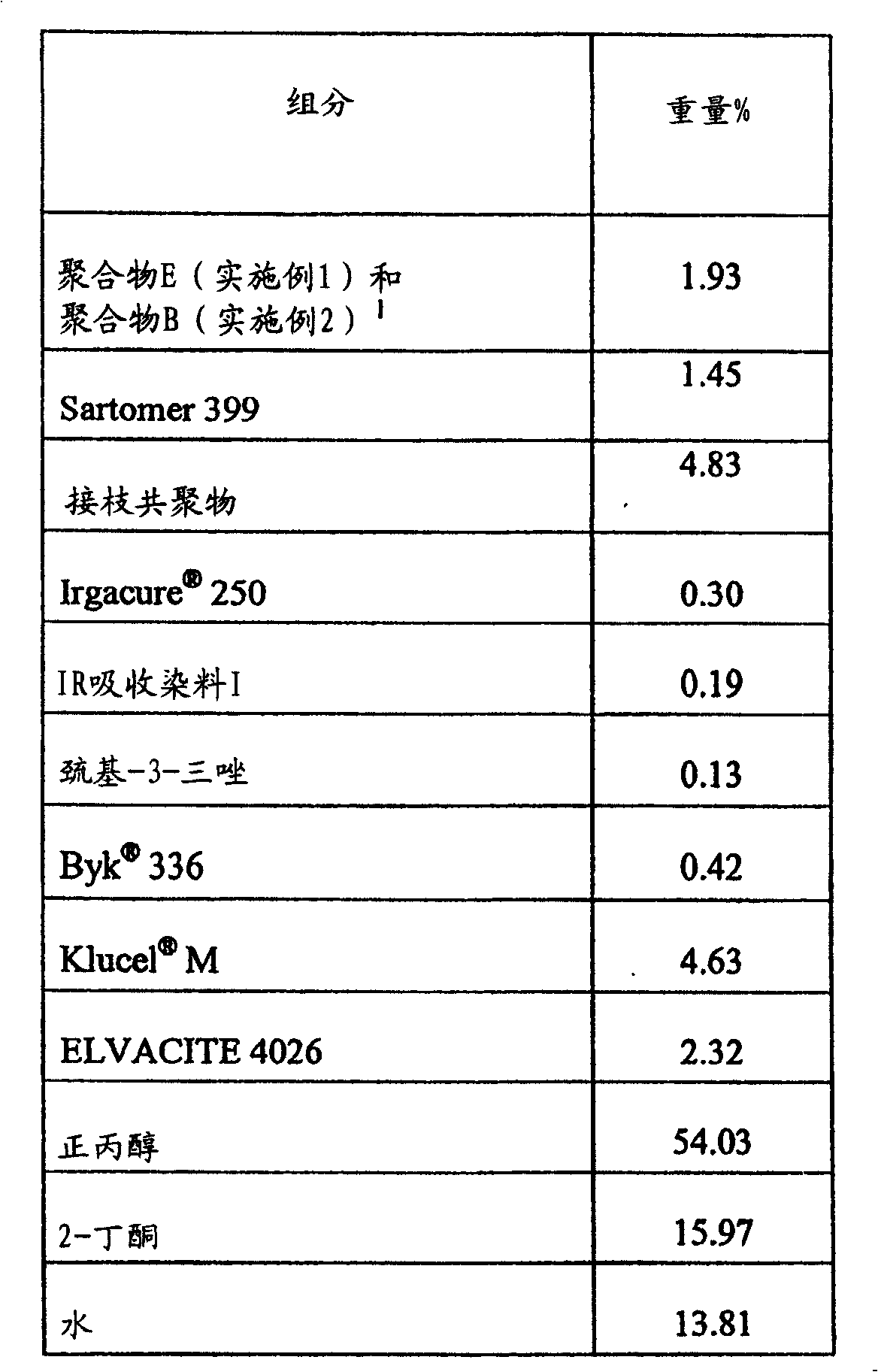

[0151] The radiation-sensitive composition described in Table I below was coated on the treated aluminum substrate to give a dry coating weight of 1.0 g / m 2 or 1.5g / m 2 , containing polymer E (Example 1) or B (Example 2) in the coating. The composition was coated with a winding rod and dried in an open chain oven set at 90°C for about 45 seconds. The aluminum base plate was brushed and phosphoric acid anodized and post-treated with polyacrylic acid.

[0152] Table I

[0153]

[0154] 1 Polymers E and B are 60 wt.% in MEK / DMAC 80:20, the acid value of polymer E is 12.8 mg KOH / g polymer E, and the acid value of polymer B is 12.6 mg KOH / g polymer E.

[0155] The resulting coating has a dry coating weight of 1.0 g / m 2 The printing plate precursors used in Examples 1 and 2 were at 300mJ / cm 2 The bottom is imaged on the traditional Creo Trendsetter 3244x imagesetter, and then directly installed on the traditional Komori press. Select printing conditions that accelerate pla...

Embodiment 3

[0160] The radiation-sensitive composition described in Table II below was coated on the treated aluminum substrate to give a dry coating weight of 1.0 g / m 2 , containing polymer D in the coating. The composition was coated with a winding rod and then dried in a Ranar open chain oven set at 90°C for about 45 seconds. The aluminum substrates were electrochemically grained and phosphoric acid anodized and post-treated with polyvinylphosphonic acid.

[0161] Table II

[0162]

[0163] 1 Polymer D is 55 wt.% in MEK / DMAC 82 / 18 and has an acid value of 41.5 mgKOH / g.

[0164] The resulting plate precursor used in Example 3 was imaged and developed on-press as in Examples 1 and 2 above. On-press development of the plate was poor, and printing was stopped after 1,000 copies were printed due to insufficient development.

[0165] In the viscosity evaluation, the printing plate precursor lifted to a height of <1 inch (2.54 cm) before falling to the table.

[0166] While improving t...

Embodiment 4 and 5

[0168] The radiation-sensitive composition described in Table III below was coated on the treated aluminum substrate to give a dry coating weight of 1.0 g / m 2 , Polymer A (Example 4) or Polymer C (Example 5) was included in the coating. The composition was coated with a winding rod and then dried in a Ranar open chain oven set at 90°C for about 45 seconds. The aluminum substrates were electrochemically grained as well as phosphoric acid anodized and post-treated with polyvinylphosphonic acid.

[0169] Table III

[0170]

[0171] n-propanol

51.72

2-butanone

18.40

water

13.44

[0172] 1 Polymer A was a 60 wt.% solution in MEK / DMAC 80:20 and Polymer C was a 60 wt.% solution in MEK / DMAC 83:17. The acid value of polymer A was 41.5 mg KOH / g polymer A, and the acid value of polymer C was 44.2 mg KOH / g polymer C.

[0173] The resulting plate precursors used in Examples 4 and 5 were imaged and developed on-press as in Examples 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com