Coal liquefaction method and device

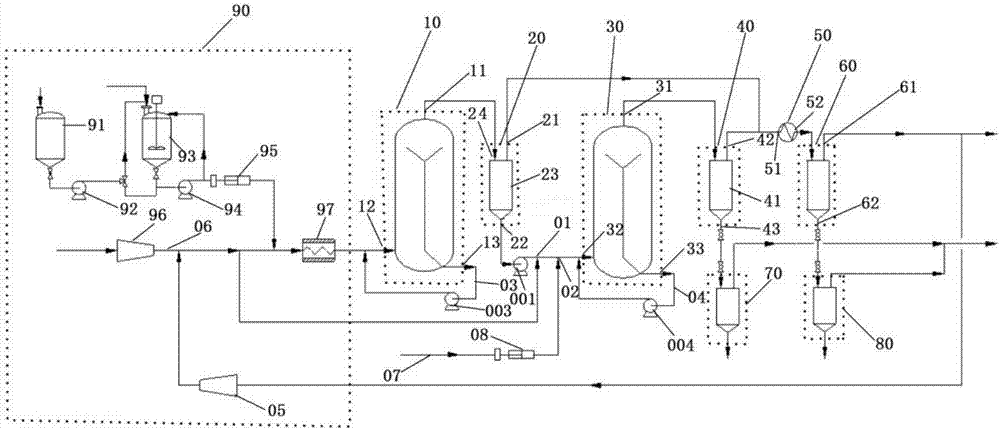

A technology of coal and liquefied products, applied in the field of coal chemical industry, can solve the problems of insufficient reaction depth, difficult to react coal, and inability to obtain conversion, etc., to achieve the effect of reducing hydrogen consumption and gas yield, and increasing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

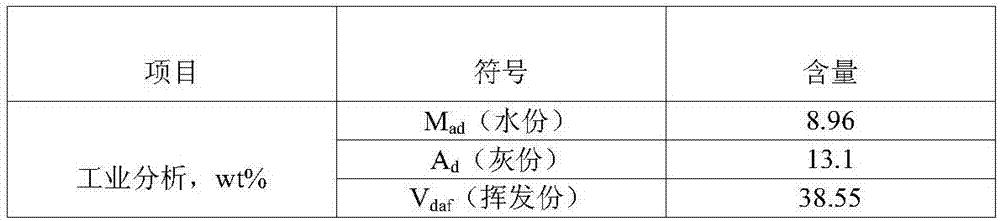

[0081] Coal slurry with a concentration of 45% (wt) (in which the particle size of coal powder is <150um, the catalyst is a coal-based loaded iron-based catalyst, the catalyst dosage is 1% of the weight of coal powder, and the rest is direct liquefaction and hydrogenation of coal with a certain hydrogen supply capacity oil) into the coal slurry preparation tank, the temperature of the coal slurry preparation tank is set at 80°C, the coal slurry is mixed with hydrogen after being boosted to 200bar by the high-pressure coal slurry pump 5, and enters the coal slurry preheater 97 (coal slurry preheating The reactor temperature is 400°C, the residence time is 10min), and then the reaction mixture enters the first liquefaction reaction unit 10 (the reactor temperature is 440°C, the residence time is 1h), and the outlet product of the first stage of the reactor enters the first product separation unit 20 for further Separation of gas-liquid phase products (the temperature of the high-...

Embodiment 2

[0083] Coal slurry concentration is 5% (wt), other is with embodiment 1.

Embodiment 3

[0085] Coal slurry concentration is 50% (wt), other is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com