Multiple stage fluidized-bed reactor and method for synthesizing chloroethylene

A fluidized bed reactor and fluidized bed technology, applied in chemical instruments and methods, organic chemistry, hydrogen halide addition and preparation, etc., can solve the problems of poor temperature control, low production intensity, and inability to meet the deep conversion of acetylene alone. , to achieve the effect of reducing operating instrument and control costs, large production throughput, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

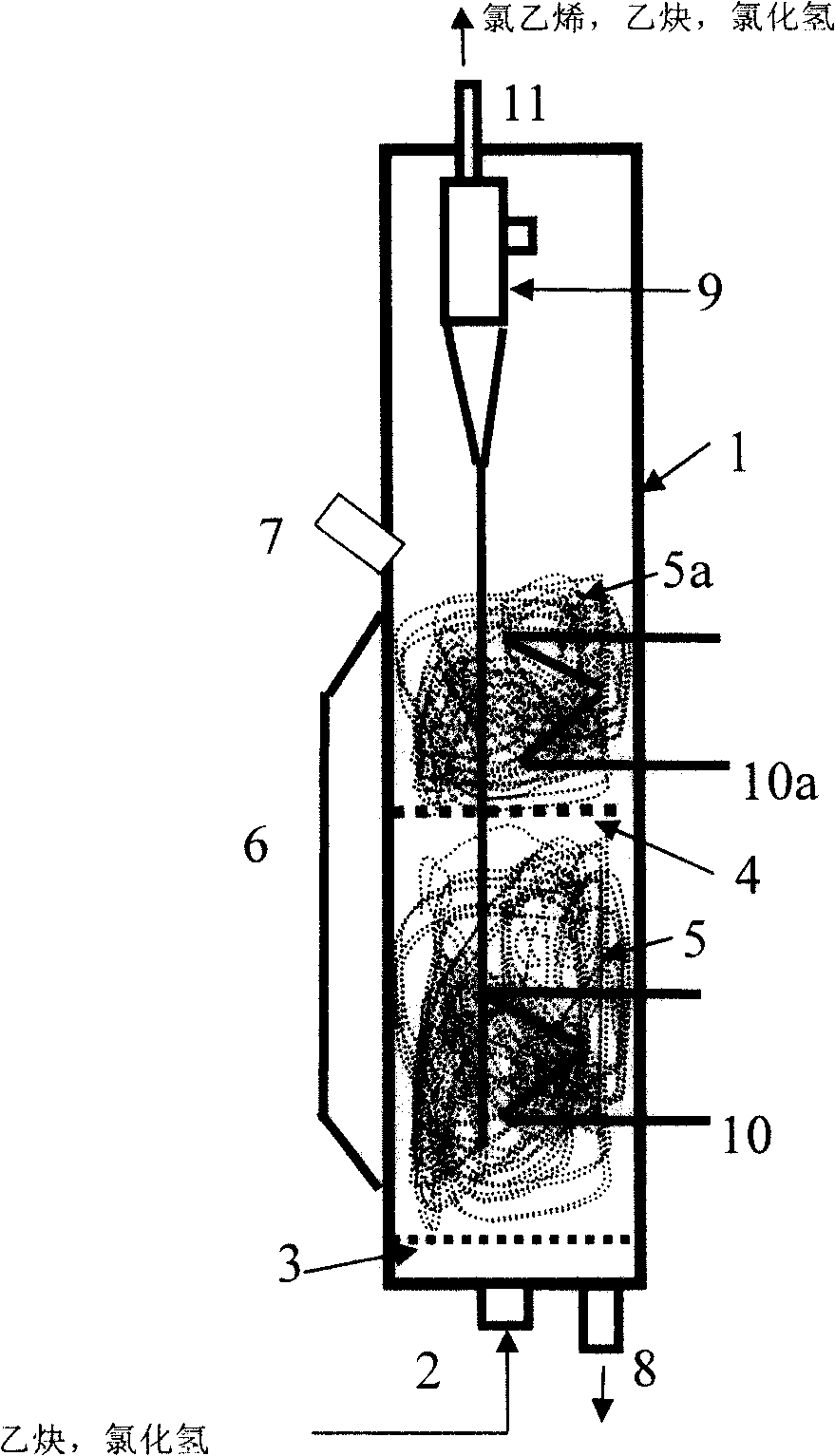

[0048] The inlet (2) for gas entering the fluidized bed, the gas distributor (3), the heat exchange tube (10), the horizontal perforated gas distribution plate (4), the heat exchange tube (10a), the outer catalyst overflow tube (6 ), the inlet (7) where the catalyst enters the fluidized bed, the outlet (8) where the deactivated catalyst is discharged from the fluidized bed, the cyclone separator (9) and the outlet (11) where the gas goes out of the fluidized bed and the fluidized bed ( 1) are connected to each other to form a complete two-stage fluidized bed (1). like figure 1 as shown, figure 1 The schematic diagram of the two-stage fluidized bed reactor (containing an outer catalyst overflow pipe) for the synthesis of vinyl chloride provided by the present invention, wherein, the distance between the gas distributor (3) and the horizontal perforated gas distribution plate (4) is 10 times the diameter of the fluidized bed. The distance below the outer catalyst overflow pip...

Embodiment 2

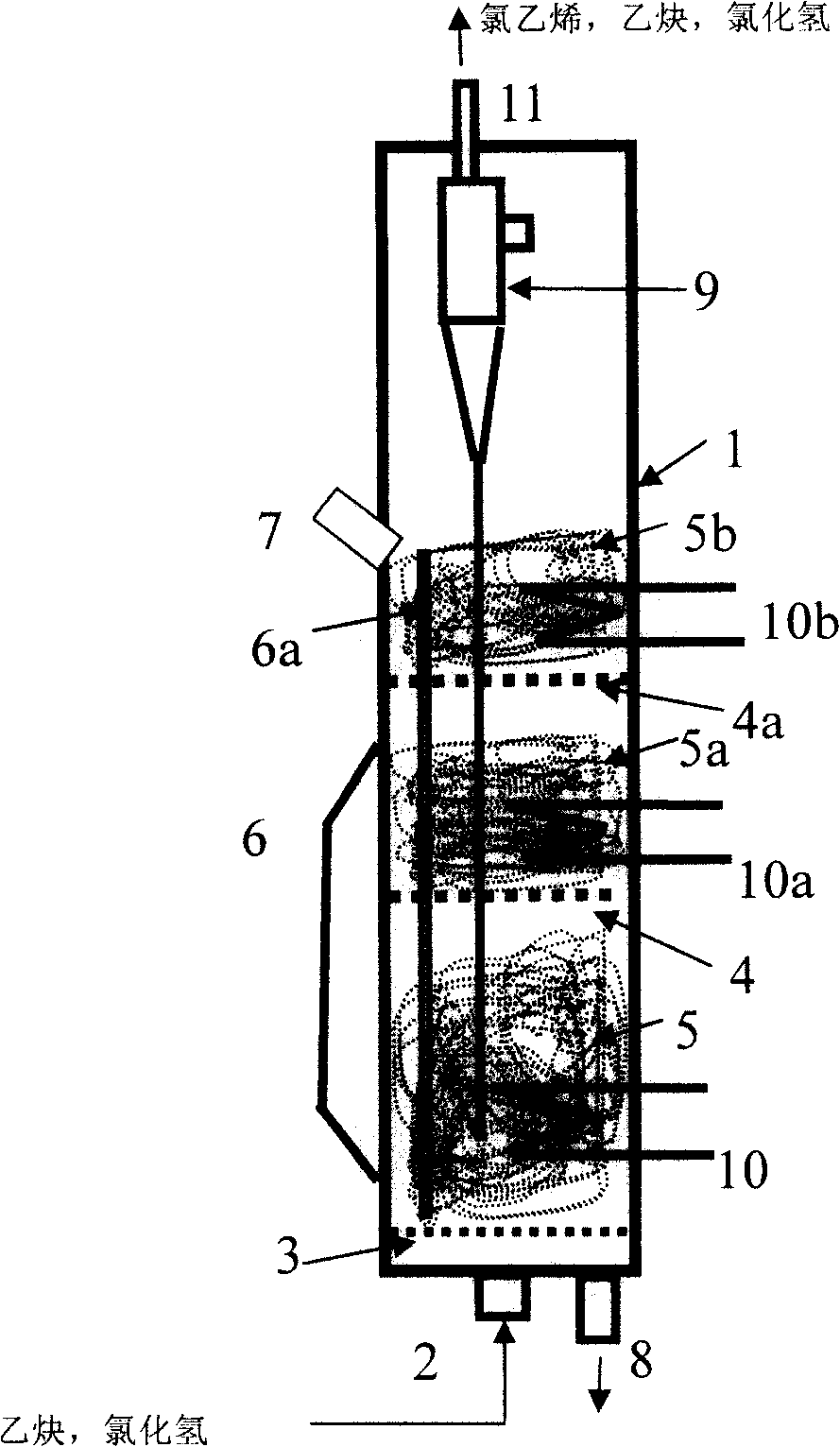

[0053] The inlet (2) for gas entering the fluidized bed, the gas distributor (3), the heat exchange tube (10), the horizontal perforated gas distribution plate (4), the heat exchange tube (10a), the outer catalyst overflow tube (6 ), horizontal perforated gas distribution plate (4a), inner catalyst overflow pipe (6a), heat exchange pipe (10b), catalyst inlet (7) into the fluidized bed, outlet of deactivated catalyst discharged from the fluidized bed ( 8), the cyclone separator (9) and the gas outlet (11) of the fluidized bed are successively connected with the cylinder wall of the fluidized bed (1) to form a complete three-stage fluidized bed (1), as figure 2 as shown, figure 2 The schematic diagram of the three-stage fluidized-bed reactor (containing an outer catalyst overflow pipe and an inner catalyst overflow pipe) for the synthesis of vinyl chloride provided by the present invention, wherein, the gas distributor (3) and the transverse gas distribution plate with holes ...

Embodiment 3

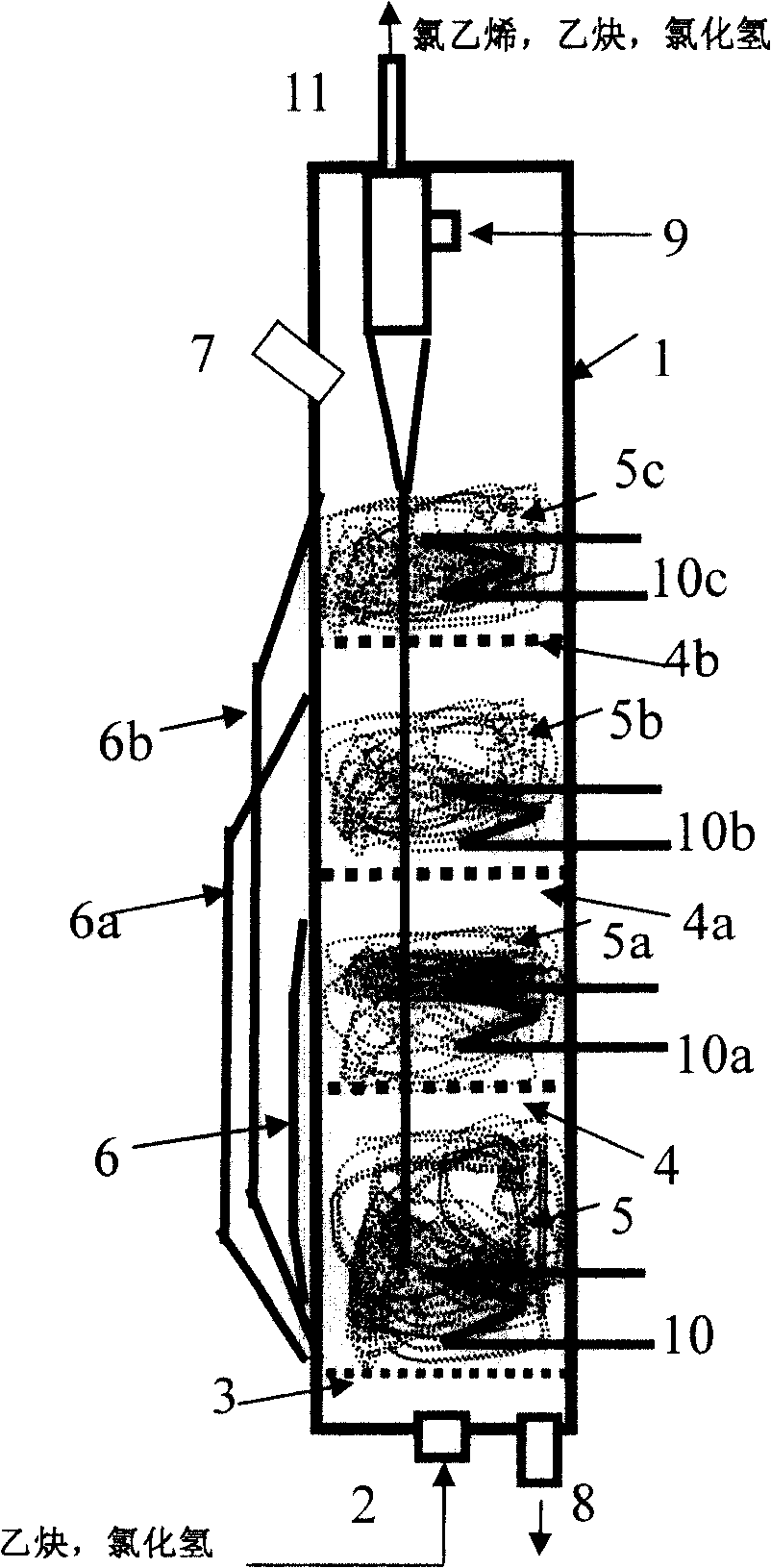

[0058] The inlet (2) for gas entering the fluidized bed, the gas distributor (3), the heat exchange tube (10), the horizontal perforated gas distribution plate (4), the heat exchange tube (10a), the outer catalyst overflow tube (6 ), horizontal perforated gas distribution plate (4a), external catalyst overflow pipe (6a), heat exchange tube (10b), horizontal perforated gas distribution plate (4b), external catalyst overflow pipe (6b), heat exchange tube (10c), the inlet (7) where the catalyst enters the fluidized bed, the outlet (8) where the deactivated catalyst is discharged from the fluidized bed, the cyclone separator (9) and the outlet (11) where the gas goes out of the fluidized bed are connected with the fluidized bed successively The cylinder walls of the bed (1) are connected to form a complete four-stage fluidized bed (1), such as image 3 as shown, image 3 The schematic diagram of the four-stage fluidized-bed reactor (containing three outer catalyst overflow pipes)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com