Preparation method of marine fuel oil

A technology for fuel oil and marine use, which is applied in the field of preparation of marine fuel oil, and can solve problems such as short operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

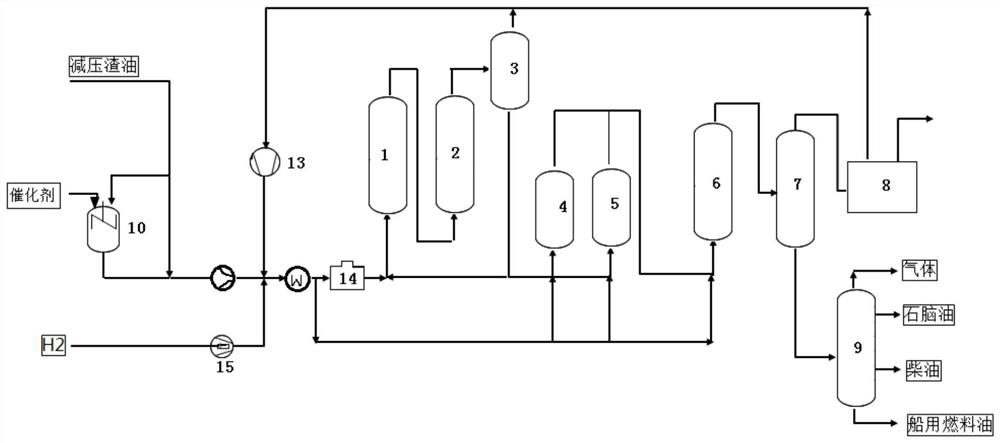

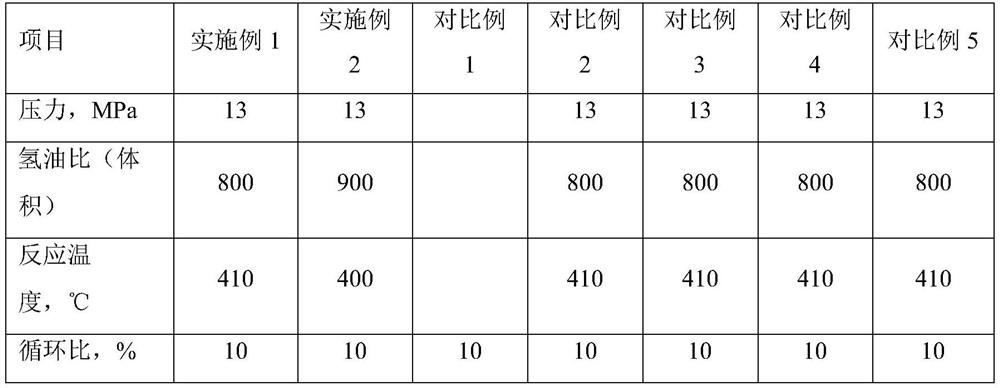

[0058] Both Example 1 and Example 2 were used figure 1 shown process flow. see figure 1 As shown, after a part of the raw oil such as vacuum residue is mixed with the hydrocracking catalyst through the stirring device 10, it is mixed with the remaining part of the oil vacuum residue and the hydrogen delivered by the new hydrogen compressor 15 through the heater 14. After preheating, they enter the paddle bed hydrocracking reactor R11 and the paddle bed hydrocracking reactor R2 2 in turn for hydrocracking, and the hydrocracked products enter the gas-liquid separator S1 3 for gas-liquid separation, wherein the obtained The gas is mixed with new hydrogen through the circulating hydrogen compressor 13 and enters the paddle bed hydrocracking reactor R11 and paddle bed hydrocracking reactor R2 2 again; a part of the obtained liquid product is mixed with fresh raw materials as circulating oil and then enters the paddle state. Bed hydrocracking reactor R1 1, paddle bed hydrocracking...

Embodiment 2

[0063] The difference between this example and Example 1 is that the raw material oil A is replaced by the raw material oil B, the main properties of the raw material oil B are listed in Table 1, the slurry bed hydrocracking catalyst is added in an amount of 500 μg / g, and the specific technological process The same as in Example 1, with the conditions changed as shown in Tables 3 and 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com