Hydrogenation preprocessing method for coal tar raw material

A hydrogenation pretreatment and coal tar technology, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of affecting the operation cycle of the device, not considering the removal of metals, and the increase of bed pressure drop, etc., to achieve The effect of long operation period of the device, extended operation period and excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

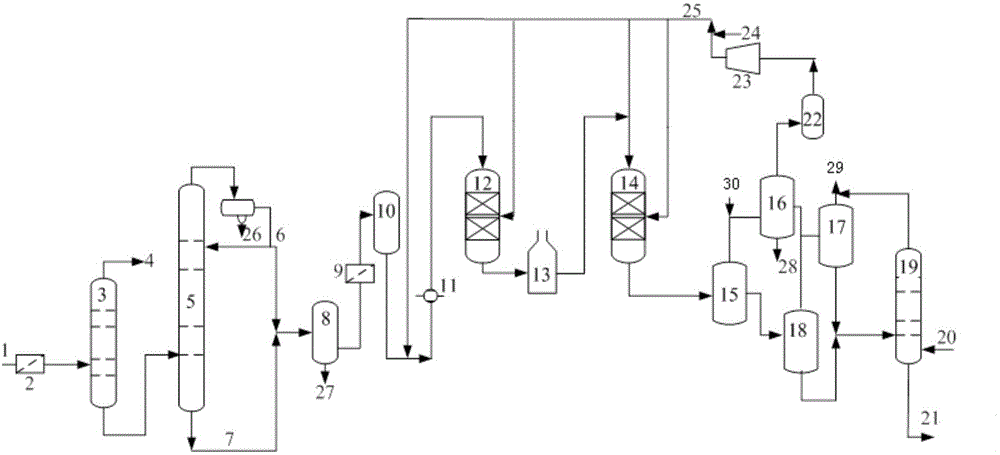

[0091] With the coal tar raw material to be pretreated in Table 1 as the raw material, it enters the degassing tower and the dehydration tower successively after being filtered by a primary filter, and obtains the coal tar raw material after dehydration, wherein, in the coal tar raw material after the dehydration The dissolved oxygen content is 0.45 μL / L, and the water content is 260 μg / g; then it is sequentially combined with the hydrogenation protection catalyst in the first prehydrogenation reactor and the hydrogenation protection catalyst in the second prehydrogenation reactor and deasphaltene Catalyst contact reaction, the reaction effluent is separated by the post-separation system to separate the water generated by the reaction, the hydrogen-rich cycle gas, and the liquid-phase hydrocarbon effluent, and the liquid-phase hydrocarbon stream enters the stripping tower to remove hydrogen sulfide and ammonia, etc. , the stripper bottom effluent is the pretreated coal tar acco...

Embodiment 2

[0100] With the coal tar raw material to be pretreated in Table 1 as the raw material, it enters the degassing tower and the dehydration tower successively after being filtered by a primary filter, and obtains the coal tar raw material after dehydration, wherein, in the coal tar raw material after the dehydration The dissolved oxygen content is 0.4 μL / L, and the water content is 240 μg / g; then it is sequentially combined with the hydrogenation protection catalyst in the first prehydrogenation reactor and the hydrogenation protection catalyst in the second prehydrogenation reactor and deasphaltene Catalyst contact reaction, the reaction effluent is separated by the post-separation system to separate the water generated by the reaction, the hydrogen-rich cycle gas, and the liquid-phase hydrocarbon effluent, and the liquid-phase hydrocarbon stream enters the stripping tower to remove hydrogen sulfide and ammonia, etc. , the stripper bottom effluent is the pretreated coal tar accor...

Embodiment 3

[0109] With the coal tar raw material to be pretreated in Table 1 as the raw material, it enters the degassing tower and the dehydration tower successively after being filtered by a primary filter, and obtains the coal tar raw material after dehydration, wherein, in the coal tar raw material after the dehydration The dissolved oxygen content is 0.48 μL / L, and the water content is 270 μg / g; then it is sequentially combined with the hydrogenation protection catalyst in the first prehydrogenation reactor and the hydrogenation protection catalyst in the second prehydrogenation reactor and deasphaltene Catalyst contact reaction, the reaction effluent is separated by the post-separation system to separate the water generated by the reaction, the hydrogen-rich cycle gas, and the liquid-phase hydrocarbon effluent, and the liquid-phase hydrocarbon stream enters the stripping tower to remove hydrogen sulfide and ammonia, etc. , the stripper bottom effluent is the pretreated coal tar acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com