Two-stage hydrocracking method for high-nitrogen raw material

A technology for hydrocracking, high nitrogen raw materials, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of low operating space velocity, increased energy consumption, high reaction temperature, etc., to improve hydrogen partial pressure , The effect of reducing the content of hydrogen sulfide and ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

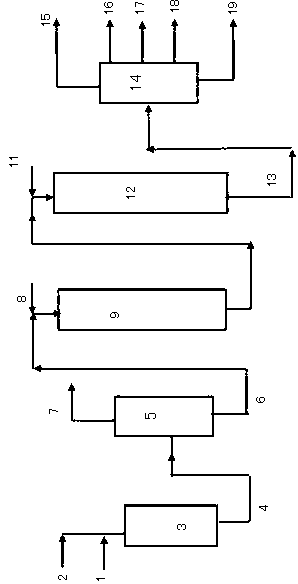

Image

Examples

Embodiment 1

[0024] Example 1 is an example of a single-pass flow process, and the tail oil is not recycled to illustrate the advanced nature of the two-stage hydrocracking process for processing high-nitrogen raw materials. Conditions and results are shown in Table 1 below.

[0025] Table 1 Example of feed oil single pass process.

[0026] implementation plan Example 1 Reference example 1 Reference example 2 Raw oil properties Density / kg·m -3 947.3 947.3 947.3 Distillation range / ℃ 275~548 275~548 275~548 Sulfur content / mass% 3.00 3.00 3.00 Nitrogen content / μg·g -1 3453 3453 3453 Process conditions first stage catalyst FF-36 FF-36 FF-36 / FC-50 second stage catalyst FF-36 / FC-50 FC-50 / Nitrogen removal rate in the first stage, % 82 Product 10μg / g / Pressure / MPa 15.7 15.7 15.7 Temperature / °C (for each catalyst) 375 / 385 / 381 398 / 382 398 / 415 Volumetric space velocity / h ...

Embodiment 2

[0028] Example 2 process flow: two-stage hydrocracking, 385°C fraction is recycled to the inlet of the second stage hydrofining reactor; Example 3 process flow: two-stage hydrocracking, 350°C fraction is recycled to the second stage hydrofining reactor Reactor inlet; reference example 3 process flow: one-stage hydrocracking, >385°C fraction recycled to hydrofining reactor inlet; reference example 4 process flow: two-stage hydrocracking, >350°C fraction recycled to hydrofining reaction device entrance. The total reaction pressure is 15.7MPa.

[0029] Table 2 The main properties of the feed oil used in the two-stage full cycle examples and comparative examples.

[0030] Density (20℃) / kg·m -3 947.3 Distillation range / ℃ 275~548 Sulfur content, mass % 3.00 Nitrogen content / μg·g -1 3453 Freezing point / ℃ 34 BMCI value 65.4

[0031] Table 3 Reaction conditions and product distribution of two-stage full cycle examples and comparative exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com