A kind of inferior heavy distillate oil hydrotreating method

A heavy distillate oil, hydrotreating technology, applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of high reaction pressure, shortened operation period, high reaction temperature, etc., and achieve the reduction of hydrogen sulfide and Effects of ammonia content, improving effluent quality, and reducing reaction temperature

Active Publication Date: 2017-01-11

CHINA PETROLEUM & CHEM CORP +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

CN101007964 discloses a hydrogenation method for producing high-quality catalytic cracking raw materials, but its operating pressure is low, and it is not suitable for processing high-nitrogen raw materials. CN101987967 discloses a hydrogenation method for vacuum deep-drawing wax oil, which adopts a two-stage flow process, However, the first stage uses a hydrogenation protection agent and demetallization protection agent with very weak activity, and the second stage uses a hydrodesulfurization and hydrodenitrogenation catalyst. When processing raw materials with high nitrogen content, the overall activity of the catalyst is low. The amount is not high, or the processing depth is not high

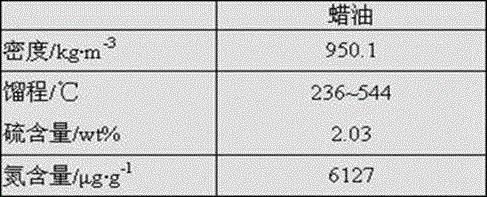

[0005] With the deteriorating quality of crude oil and the increase of impurity content, as well as the development of crude oil decompression and deep pressure and other unconventional energy sources, the impurity content of raw materials for hydroprocessing is getting higher and higher, especially the nitrogen content of some raw materials for hydroprocessing. The content is relatively high, but the existing hydroprocessing method requires high reaction temperature, high reaction pressure or low operating space velocity when dealing with the hydrogenation feedstock with high nitrogen content, the processing capacity of the device is reduced, and the energy consumption Increased, shortened operating cycle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

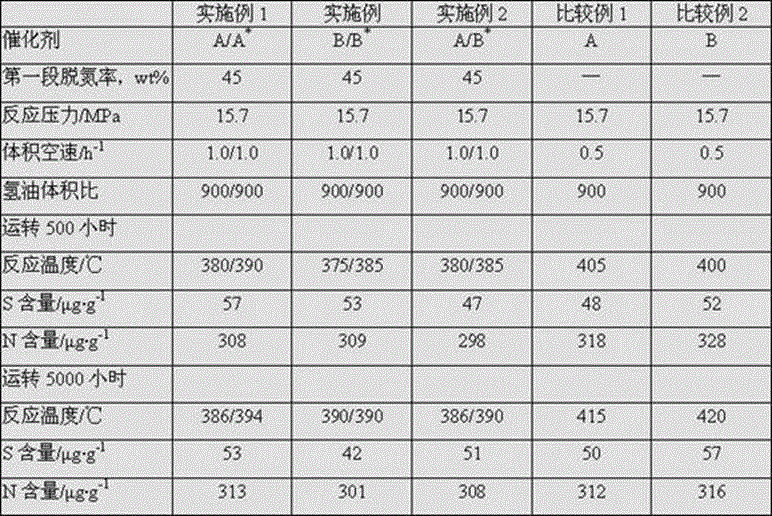

Embodiment 1

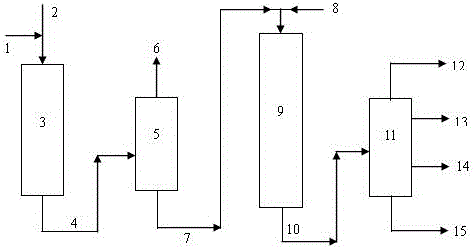

[0046] use figure 1 Process flow shown. Hydrofinishing catalyst B was used in both the first and second stages.

Embodiment 2

[0048] use figure 1 Process flow shown. Hydrofinishing catalyst A was used in both the first and second stages.

Embodiment 3

[0050] use figure 1 The process flow shown uses hydrofinishing catalyst A in the first stage and hydrofinishing catalyst B in the second stage.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a poor-quality heavy distillate oil hydrotreating method. According to the method, under a hydrorefining condition, a heavy distillate oil raw material and hydrogen gas are mixed and enter a first-stage reaction zone to carry out a hydrotreating reaction, the first-stage reaction zone effluent is subjected to gas-liquid separation to obtain a liquid phase, the liquid phase enters a second-stage reaction zone to carry out a hydrotreating reaction, and the second-stage reaction zone reaction effluent is separated to obtain the hydrotreating reaction product. Compared with the existing hydrotreating technology in the prior art, the method of the present invention has the following advantages that: the product quality and the processing capability of the device can be substantially improved, or the operating pressure can be reduced and the operating cost can be reduced under the same product quality and processing capability condition.

Description

technical field [0001] The invention discloses a hydrotreating method, in particular a two-stage hydrotreating method for processing inferior heavy distillate oil raw materials. Background technique [0002] With the rapid development of my country's national economy, the oil processing capacity has grown rapidly. At the same time, the high price of crude oil has made the proportion of crude oil procurement cost in the total cost of refining increased significantly, and the profit margin of oil refining enterprises has been greatly reduced. In addition, due to the deterioration of crude oil quality year by year, the substantial increase in the processing volume of imported high-sulfur and high-nitrogen crude oil, the increasingly strict requirements of environmental protection on the refining process and the quality of petroleum products, and the continuous increase in the market demand for clean oil products and chemical raw materials. The market has put forward higher req...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G65/02

CPCC10G67/02

Inventor 白振民刘继华牟春生陈金锋

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com