Hydrogenation method for lubricating base oil production from inferior raw materials

A technology for lubricating base oils and low-quality feedstock oils, applied in lubricating compositions, hydrotreating processes, petroleum industry, etc., can solve the problems of not improving the product quality of hydrocracking units, reducing equipment investment and operating costs, and achieving The effect of reducing the content of hydrogen sulfide and ammonia, increasing the partial pressure of hydrogen in the system, and reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

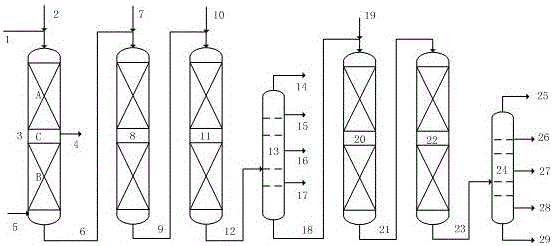

[0046] use figure 1 In the process flow shown, the hydrocracking in the third stage is a one-pass process, and all the hydrocracking tail oil undergoes isomerization dewaxing reaction. Catalyst A is loaded in the first section, and catalyst A is loaded in the second section. The upper part of the first-stage reaction zone adopts gas-liquid parallel flow reaction, and the lower part adopts gas-liquid countercurrent reaction, and the catalyst loading volume ratio of the parallel flow section and the countercurrent section is 1:1.

Embodiment 2

[0048] use figure 1 In the process flow shown, both the first section and the second section are filled with catalyst B, and the others are the same as in Example 1.

Embodiment 3

[0050] use figure 1 In the process flow shown, catalyst A is filled in the first section, catalyst B is filled in the second section, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com