Hydrogenation method for producing lubricating oil base oil through poor-quality raw material

A technology for lubricating base oil and low-quality feedstock oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of not improving the product quality of the hydrocracking unit, reducing device investment and operating costs, etc., and achieving Effects of reducing hydrogen sulfide and ammonia content, increasing hydrogen partial pressure, and reducing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

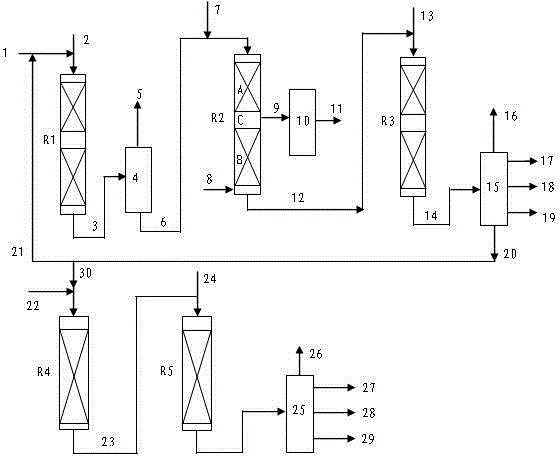

[0051] use figure 1 In the process flow shown, the hydrocracking in the third stage is a one-pass process, and all the hydrocracking tail oil undergoes isomerization dewaxing reaction. The first stage is loaded with catalyst A, and the second stage is filled with catalyst B. The upper part of the refining reaction zone of the second stage adopts gas-liquid parallel flow reaction, and the lower part adopts gas-liquid countercurrent reaction, and the catalyst loading volume ratio of the parallel flow section and the countercurrent section is 1:1.

Embodiment 2

[0053] Both the first section and the second section are filled with catalyst B, and the others are the same as in Example 1.

Embodiment 3

[0065] The main process is as figure 1 As shown, the >370°C distillate part is recycled to the inlet of the second-stage hydrotreating reactor, and the circulation amount is 25% of the tail oil. Control the denitrification rate of the first stage reaction zone to 75wt%. The test results are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com