Ultra-deep desulfurization and dearomatization method for diesel oil

A technology for deep desulfurization and dearomatization, which is used in the petroleum industry, processing hydrocarbon oil, refining to remove heteroatoms, etc. It can solve the difficulty of taking into account the dual requirements of ultra-deep desulfurization and aromatic saturation of oil products, unable to exert the advantages of catalysts, and unfavorable catalysts. Problems such as long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Prepare sodium aluminate with a concentration of 12wt%, add a certain amount of 25wt% tetrapropylammonium hydroxide after dissolving, stir evenly, and then add ethyl orthosilicate with the same volume ratio (relative to tetrapropylammonium hydroxide) , after stirring evenly, put it in a kettle, age at 100°C for 4 hours to obtain a clear solution, after cooling down to room temperature, add a certain amount of polydimethyldiallyl ammonium chloride, after stirring evenly, the feeding of each raw material molar ratio as Al 2 o 3 : Na 2 O : SiO 2 :TPAOH:BM:H 2 O counted as 1.0:1.0:20:8.5:0.25:1200. Crystallize the gel obtained above in an autoclave at 180°C for 2 days, take it out, wash it, dry it, and perform ion exchange. The temperature was 80°C, and the exchange was performed twice. After each ammonium exchange, the obtained samples were dried at 120°C for 6 h and calcined at 520°C for 4 h to finally obtain H-type mesoporous ZSM-5 molecular sieves. Molecular sieve...

Embodiment 2

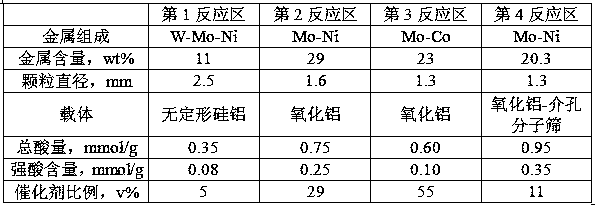

[0065] Catalyst Grading Scheme

[0066]

Embodiment 3

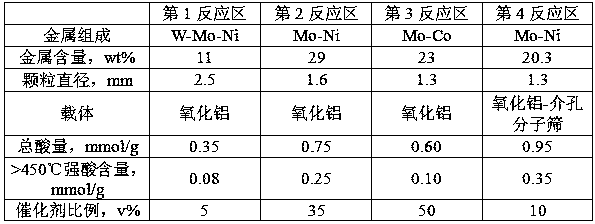

[0068] Catalyst Grading Scheme

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com