Two-gear automatic gearbox for pure electric vehicle

An automatic transmission, pure electric vehicle technology, applied in vehicle gearboxes, electric power units, multi-gear ratio transmissions, etc., can solve the problems of high requirements for driving motors and batteries, low operating efficiency of driving motors, etc., to reduce the total volume. , The effect of expanding the range of transmission ratio and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

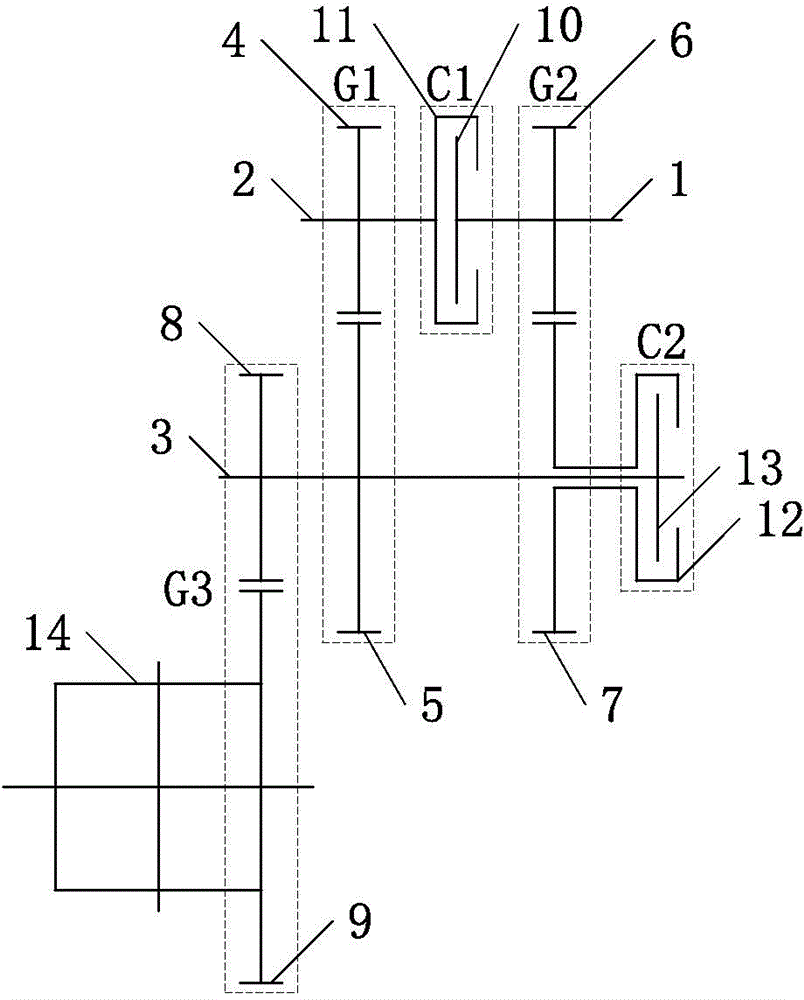

[0065] Example 1 as figure 1 As shown, a two-speed automatic transmission for a pure electric vehicle of the present invention includes an input shaft 1, a first intermediate shaft 2, a second intermediate shaft 3, a first cylindrical gear pair G1, a second cylindrical gear pair G2, a third cylindrical gear pair gear pair G3 , first torque transmitting device C1 , second torque transmitting device C2 , and differential assembly 14 . in:

[0066] 1) The cross section of the input shaft 1 is circular;

[0067] 2) The cross section of the first intermediate shaft 2 is circular;

[0068] 3) The cross section of the second intermediate shaft 3 is circular;

[0069] 4) The first cylindrical gear pair G1 is a helical cylindrical gear pair, including the first cylindrical gear pair driving gear 4 and the first cylindrical gear pair driven gear 5;

[0070] 5) The second cylindrical gear pair G2 is a helical cylindrical gear pair, including the second cylindrical gear pair driving g...

Embodiment 2

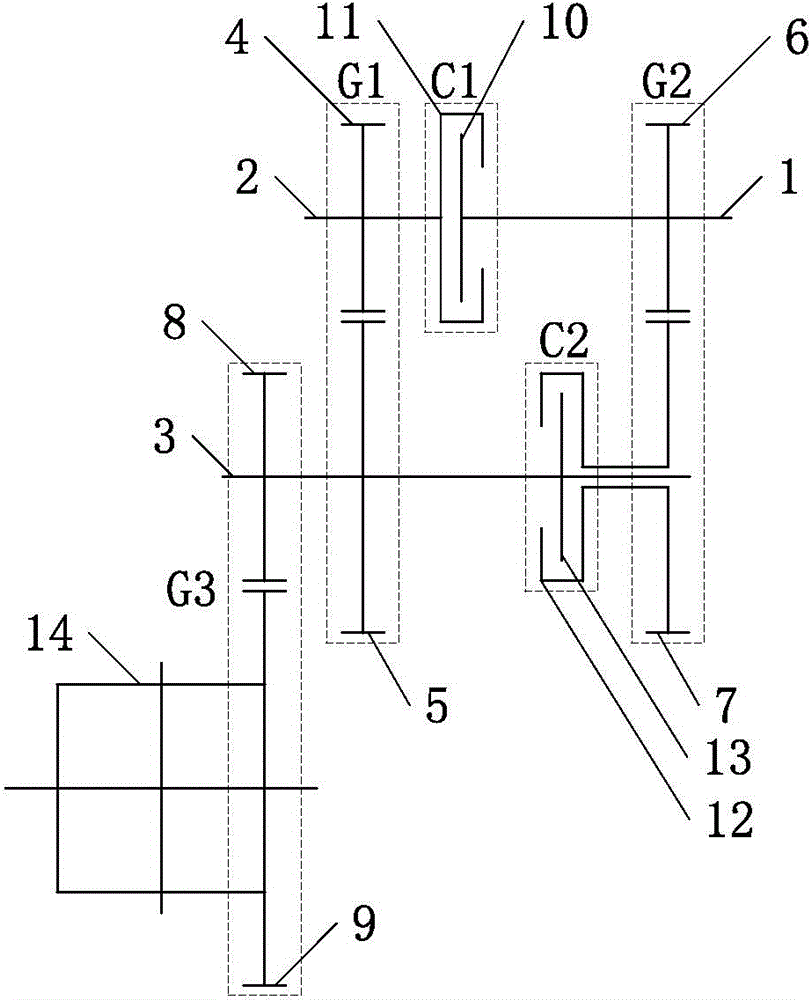

[0104] Example 2 as figure 2As shown, a two-speed automatic transmission for a pure electric vehicle of the present invention includes an input shaft 1, a first intermediate shaft 2, a second intermediate shaft 3, a first cylindrical gear pair G1, a second cylindrical gear pair G2, a third cylindrical gear pair gear pair G3 , first torque transmitting device C1 , second torque transmitting device C2 , and differential assembly 14 . in:

[0105] 1) The cross section of the input shaft 1 is circular;

[0106] 2) The cross section of the first intermediate shaft 2 is circular;

[0107] 3) The cross section of the second intermediate shaft 3 is circular;

[0108] 4) The first cylindrical gear pair G1 is a helical cylindrical gear pair, including the first cylindrical gear pair driving gear 4 and the first cylindrical gear pair driven gear 5;

[0109] 5) The second cylindrical gear pair G2 is a helical cylindrical gear pair, including the second cylindrical gear pair driving g...

Embodiment 3

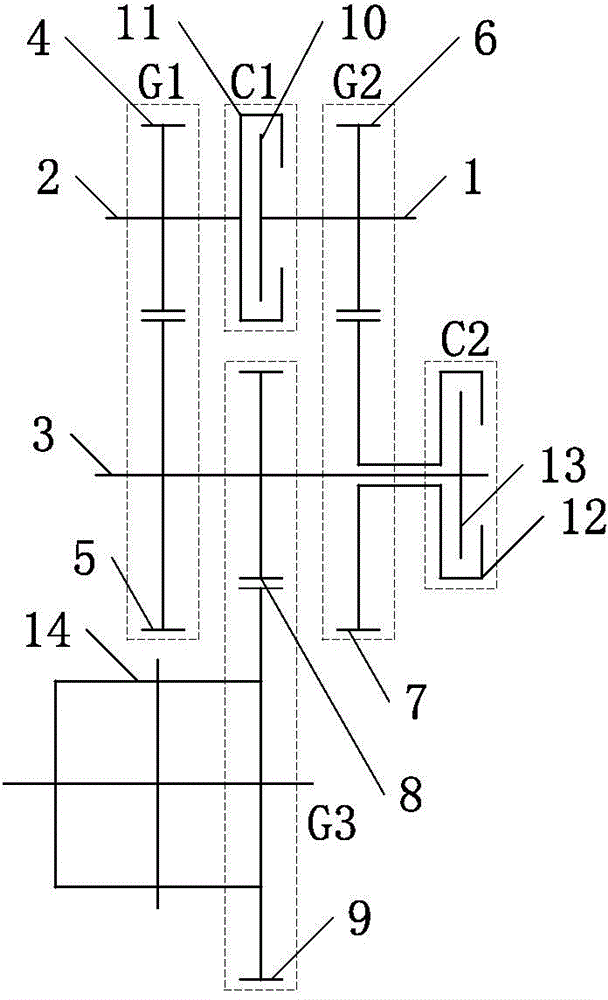

[0143] Example 3 as image 3 As shown, a two-speed automatic transmission for a pure electric vehicle of the present invention includes an input shaft 1, a first intermediate shaft 2, a second intermediate shaft 3, a first cylindrical gear pair G1, a second cylindrical gear pair G2, a third cylindrical gear pair gear pair G3 , first torque transmitting device C1 , second torque transmitting device C2 , and differential assembly 14 . in:

[0144] 1) The cross section of the input shaft 1 is circular;

[0145] 2) The cross section of the first intermediate shaft 2 is circular;

[0146] 3) The cross section of the second intermediate shaft 3 is circular;

[0147] 4) The first cylindrical gear pair G1 is a helical cylindrical gear pair, including the first cylindrical gear pair driving gear 4 and the first cylindrical gear pair driven gear 5;

[0148] 5) The second cylindrical gear pair G2 is a helical cylindrical gear pair, including the second cylindrical gear pair driving g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com