Method for improving production efficiency of aluminium oxide produced with Bayer process

A technology of Bayer method and alumina, which is applied in the field of improving the efficiency of alumina production by Bayer method, can solve the problems of not economically and effectively improving the medium circulation efficiency, high production cost, and difficult industrial application, so as to improve the medium circulation efficiency and equipment The effect of low requirements and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

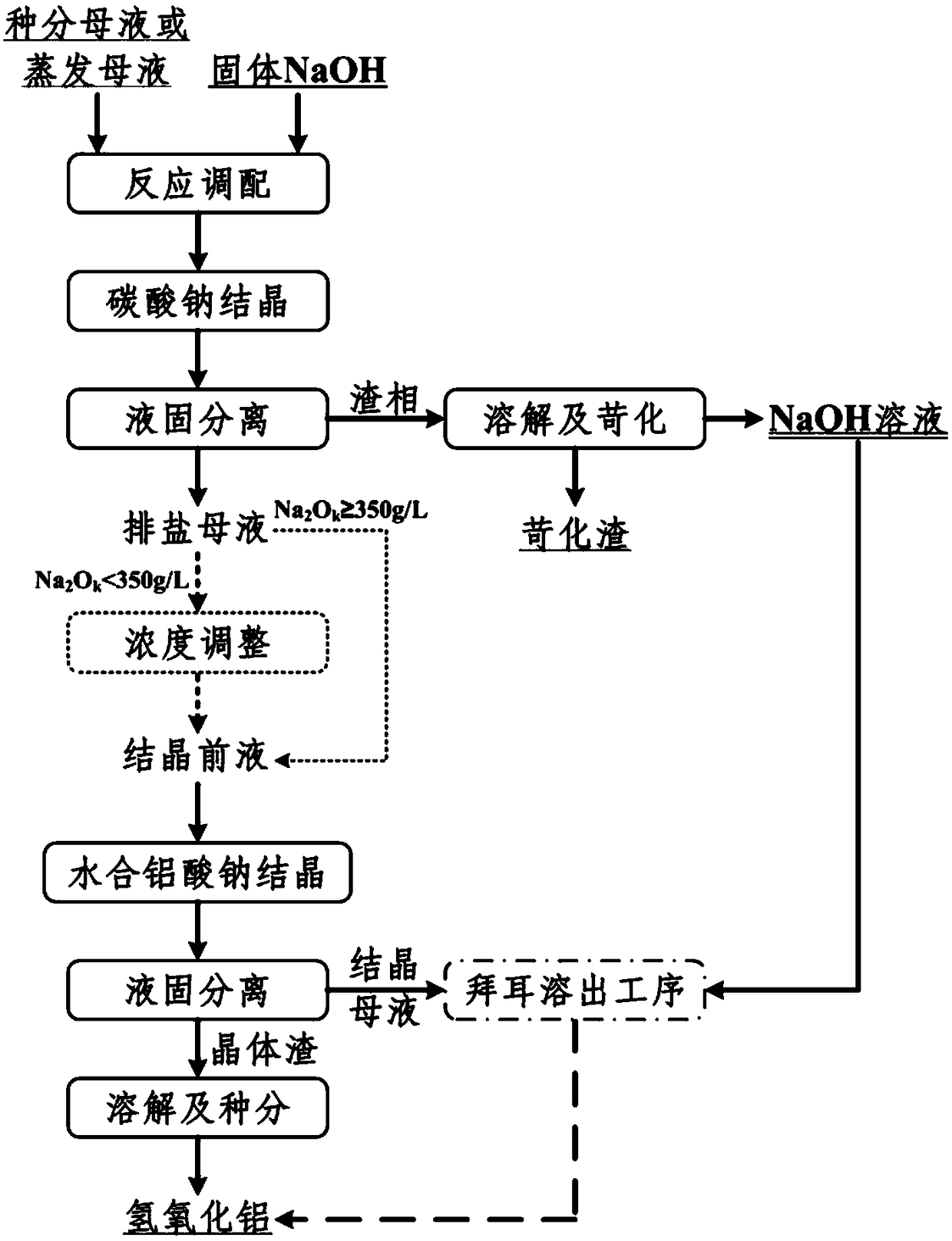

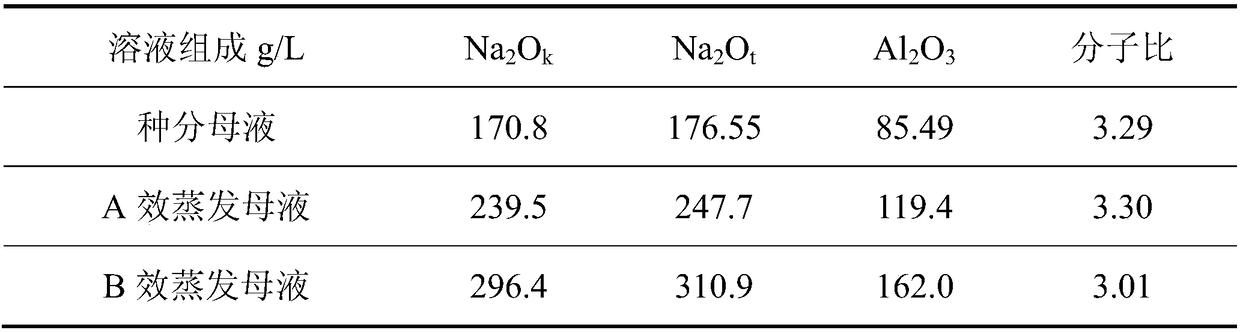

[0060] This embodiment provides a method for improving the efficiency of alumina production by the Bayer process. The mother liquor of a certain Bayer process alumina plant is used as a raw material. The main composition of the mother liquor of the alumina plant (g / L, the same below) is shown in Table 1 mentioned.

[0061] Table 1

[0062]

[0063] Its production process includes the following steps:

[0064] (1) Mix the seed separation mother liquor with solid NaOH to prepare a liquid phase NaOH 2 o k Concentration is 400g / L, the slurry that molecular ratio is 5.5, discharge salt with sodium carbonate seed crystal at 100 ℃ for 3 hours, filter to obtain sodium carbonate filter cake and Na 2 o k Concentration is 400g / L, molecular ratio is the liquid before crystallization of 5.5;

[0065] (2) Na 2 o k The pre-crystallization solution with a concentration of 400g / L and a molecular ratio of 5.5 was cooled to 45°C and crystallized for 15 hours to obtain a sodium aluminat...

Embodiment 2

[0070] This embodiment provides a method for improving the efficiency of alumina production by the Bayer process, using the evaporated mother liquor of a certain Bayer process alumina plant described in Table 1 as a raw material, and the production process is as follows:

[0071] (1) Mix the A-effect evaporation mother liquor with solid NaOH to form a liquid phase NaOH 2 o k With a concentration of 500g / L and a molecular ratio of 7.7, use sodium carbonate seed crystals to discharge salt for 3 hours at 100°C, and filter to obtain sodium carbonate filter cake and Na 2 o k Concentration is 500g / L, the liquid before crystallization that molecular ratio is 7.7;

[0072] (2) Na 2 o k The pre-crystallization solution with a concentration of 500g / L and a molecular ratio of 7.7 was cooled to 60°C and crystallized for 5 hours to obtain a sodium aluminate hydrate filter cake and a crystallization mother solution with a caustic concentration of 492g / L and a molecular ratio of 37;

[...

Embodiment 3

[0077] This embodiment provides a method for improving the efficiency of alumina production by the Bayer process, using the evaporated mother liquor of a certain Bayer process alumina plant described in Table 1 as a raw material, and the production process is as follows:

[0078] (1) Mix the B-effect evaporation mother liquor with solid NaOH to form a liquid phase NaOH 2 o k Concentration is 600g / L, the slurry that molecular ratio is 10.6, discharge salt with sodium carbonate seed crystal at 100 ℃ for 3 hours, filter to obtain sodium carbonate filter cake and Na 2 o k Concentration is 600g / L, the liquid before crystallization that molecular ratio is 10.6;

[0079] (2) Na 2 o k The pre-crystallization solution with a concentration of 600g / L and a molecular ratio of 10.6 was cooled to 50°C and crystallized for 10 hours to obtain a sodium aluminate hydrate filter cake and a crystallization mother solution with a caustic concentration of 583g / L and a molecular ratio of 42;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com