Cooperative removal method for mixed smoke CO and NOx of soot replacement heat storage type heating furnace

A collaborative removal method and heating furnace technology, applied in the field of mixed smoke CO and NOx collaborative removal of soot replacement regenerative heating furnace, can solve the problems of CO exceeding and ultra-low emission standards, double denitration system investment, and high operating costs , to achieve the effect of improving safety, stable flue gas composition and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

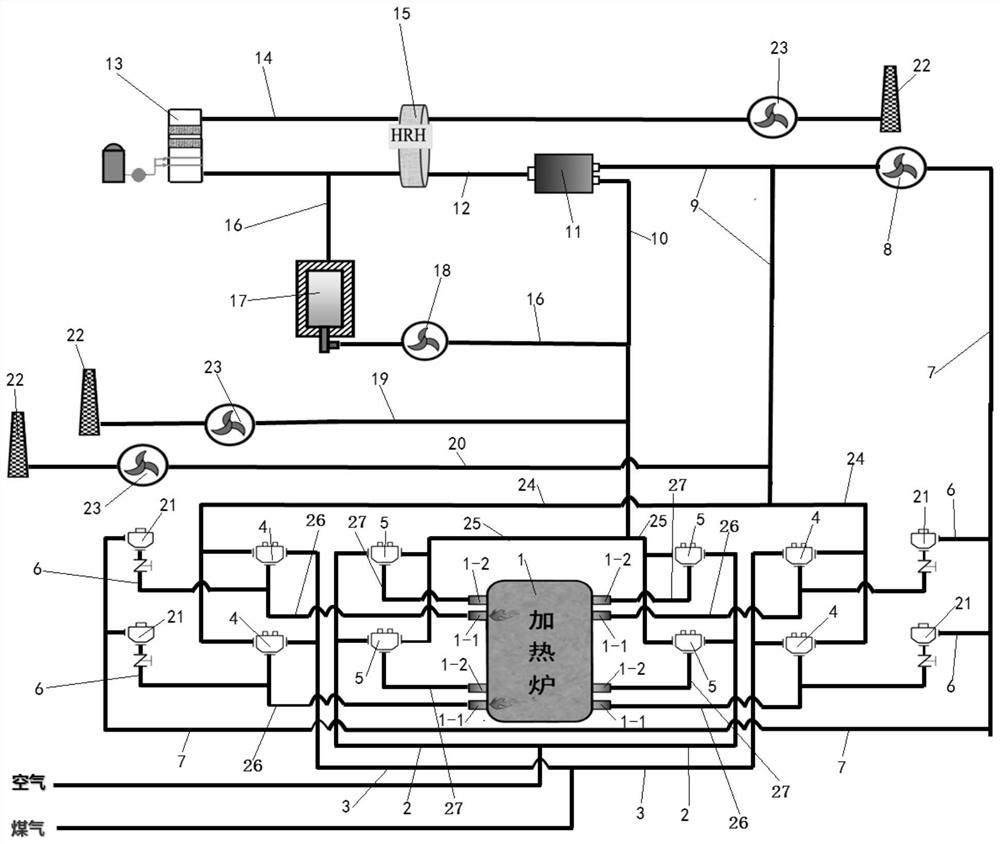

[0057]A method for synergistic removal of mixed smoke CO and NOx in a soot replacement regenerative heating furnace. N groups of openings are formed on the left and right sides of the regenerative heating furnace 1, and the left and right sides of the regenerative heating furnace 1 Regenerators (not shown in the figure) are arranged on the inside of each side, and each group of openings is an opposite air port 1-2 and a gas port 1-1, soot replacement regenerative heating furnace mixed smoke CO and The NOx synergistic removal method includes the following steps:

[0058] Select one group of openings on the left and right sides of the regenerative heating furnace 1, and the steps after selection include repeating steps ① to ④, wherein, the N groups of openings on each side of the regenerative heating furnace 1 are selected in turn (for storage One side of thermal heating furnace 1: After the first opening of this side is selected, the second opening can be selected after complet...

Embodiment 2

[0068] like figure 1 As shown, the system for realizing the synergistic removal method of CO and NOx in the soot replacement regenerative heating furnace mixed smoke in Example 1, N=2, the system includes: regenerative heating furnace 1, flue gas mixer 11, heat recovery Heat exchanger 15, air flue gas warming pipeline 16 and denitration device 13 (SCR denitration reactor);

[0069] For each group of openings: each air port 1-2 communicates with an air-smoke common pipe 27, the air-smoke common pipe 27 communicates with an air intake pipe 2, and a Air reversing valve 5, each gas port 1-1 communicates with a soot sharing pipeline 26, and the soot sharing pipeline 26 communicates with a gas inlet pipeline 3, between the soot sharing pipeline 26 and the gas inlet pipeline 3 A gas reversing valve 4 is installed, and the middle part of each soot common pipe 26 communicates with a replacement branch pipeline 6; as preferably, the air reversing valve 5 and the gas reversing valve 4 a...

Embodiment 3

[0075] The usage of the above system includes:

[0076] 1) Close the valve 21 of the replacement branch pipeline 6 on the left side of the regenerative heating furnace 1, close the valve 21 of the replacement branch pipeline 6 on the right side of the regenerative heating furnace 1, and pass the air intake pipeline 2 and the gas intake pipeline 3 Input air and gas into the air port 1-2 and the gas port 1-1 on the right side of the regenerative heating furnace 1 respectively (into the air port 1-2 on the right side of the regenerative heating furnace 1 through the air intake pipe 2 Input air, input gas in the gas port 1-1 on the right side of regenerative heating furnace 1 through gas inlet pipe 3, air and gas are input simultaneously);

[0077] Adjust the gas reversing valve 4 on the left side of the regenerative heating furnace 1 so that the soot sharing pipe 26 on the left side of the regenerative heating furnace 1 is disconnected from the gas inlet pipe 3 and the soot shari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com