Thermal cutting shear and cutting method thereof

A technology of hot cutting and cutting, applied in metal processing and other directions, can solve the problems of time-consuming and laborious installation and disassembly, temperature deviation from the control range, low production and processing efficiency, etc., to achieve fast temperature rise, more reasonable and accurate limitation and control , the effect of reducing the level of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

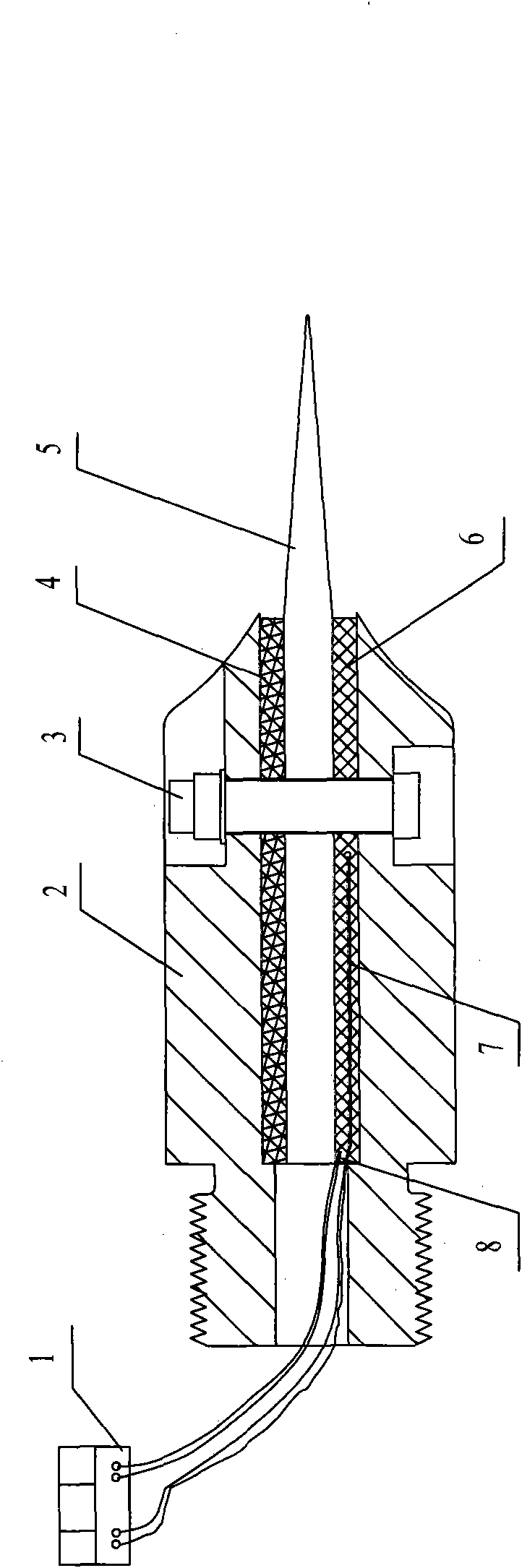

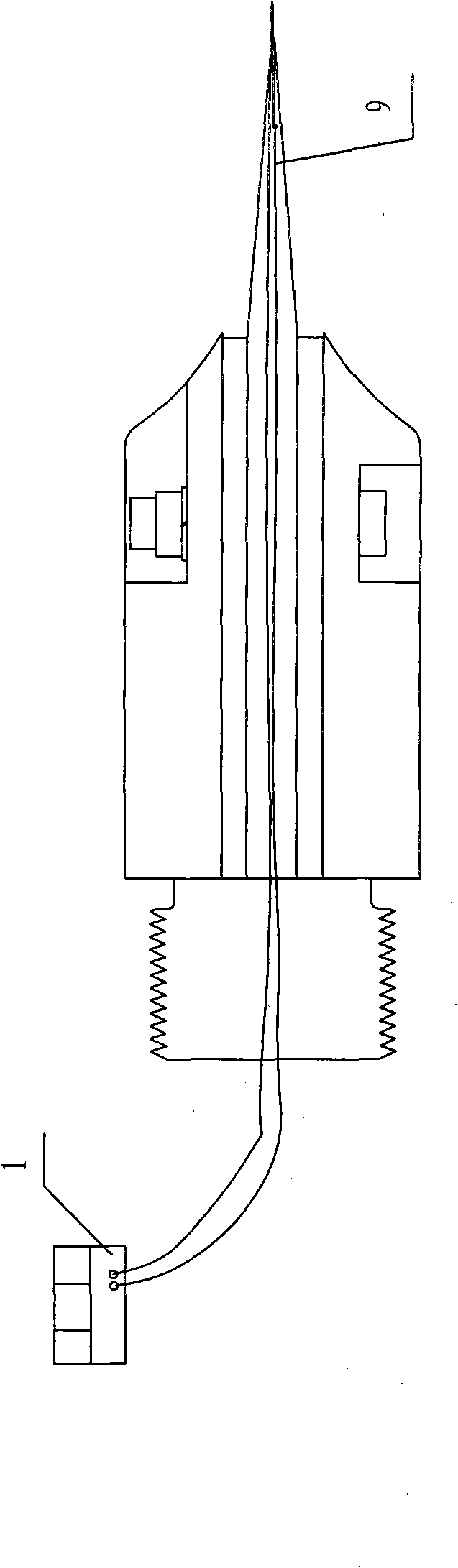

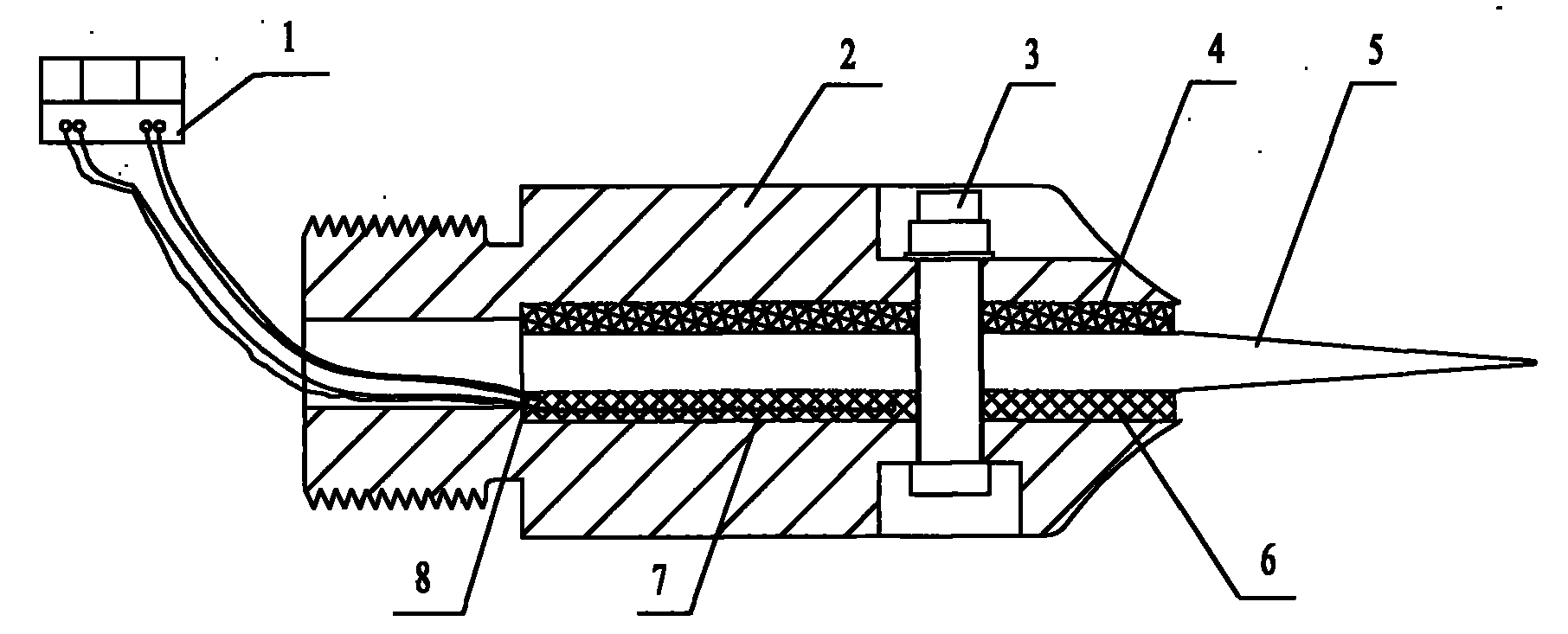

[0042] Example 1, such as figure 1 and figure 2 As shown, the hot cutter is applied to polymer material processing machinery, that is, the rubber tire manufacturing process.

[0043] The thermal cutter mainly includes a set of clamp bodies 2 and a cutter body 5 clamped and fixed between the clamp bodies 2 , and the HRC hardness value of the cutter body 5 is greater than 70.

[0044] The rear end of the clip body 2 is bolt-connected and installed with the cutter installation frame.

[0045] Between both sides of the base 51 of the cutter body 5 and the clamping body 2 , a flat heating plate 6 and a flat insulating plate 4 are lined symmetrically, respectively.

[0046] Along the longitudinal direction, the clamp body 2 , the insulation board 4 , the base 51 of the cutter body 5 , and the heating plate 6 are sequentially fastened and connected by a set of bolts 3 .

[0047] A heat source temperature sensor 7 is arranged inside the heating plate 6 , and the heat source temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com