Temperature-suction force-infiltration-stress coupled multifunctional consolidation system and operating method thereof

A multi-functional, suction technology, applied in the direction of material inspection, soil material testing, etc., can solve the problems of inability to apply high pressure, high measurement cost, low work efficiency, etc., to achieve multi-field coupling, improve measurement accuracy, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

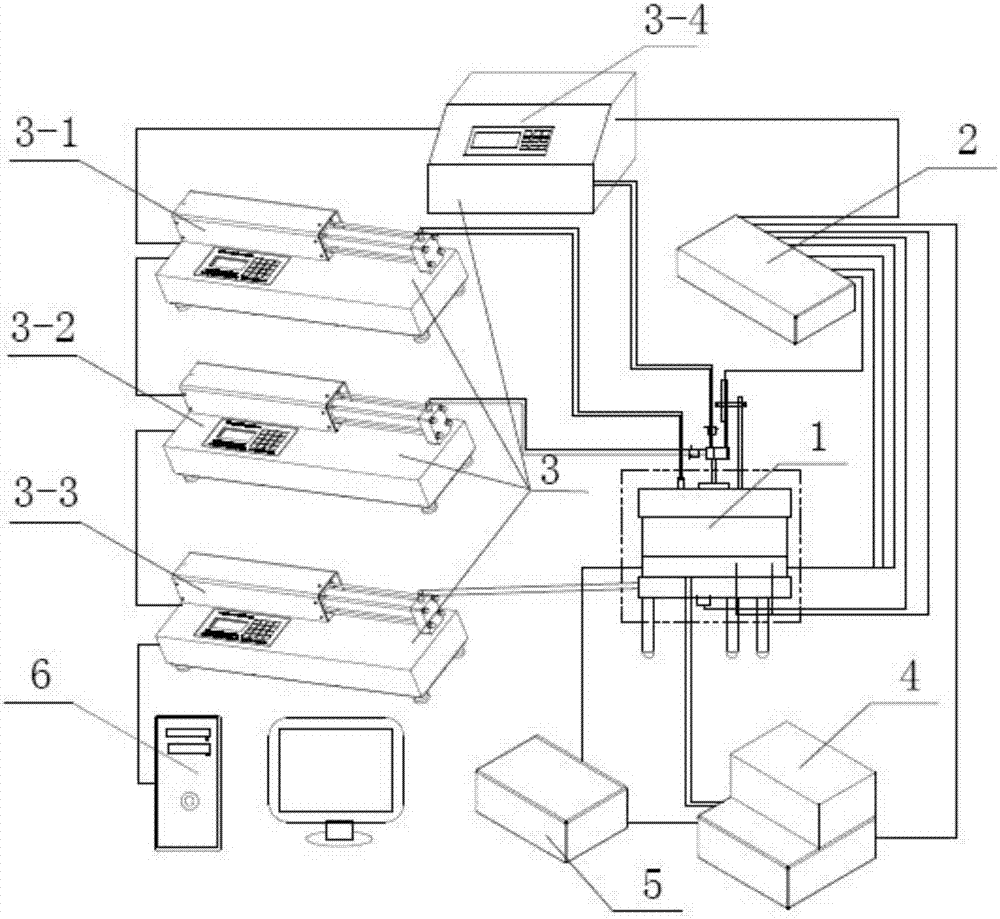

[0045] Such as Figure 1-6 As shown, a temperature-suction-permeation-stress coupled multifunctional consolidation system includes a consolidation device 1, a data acquisition device 2, a pressure control device 3, a temperature control and monitoring device 4, a shear wave sending and Receiving device 5 and computer 6.

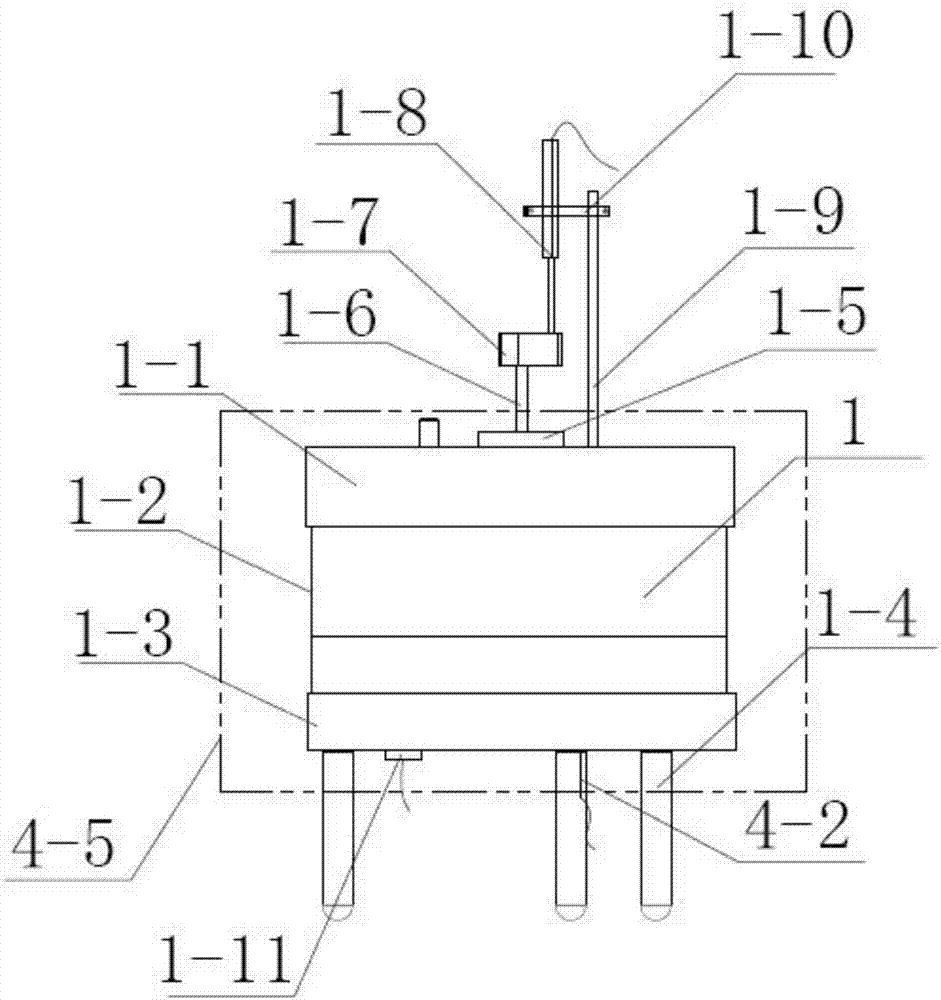

[0046] The consolidation device 1 includes an upper cover 1-1, a plexiglass cylinder wall 1-2, a base 1-3, a support shaft 1-4, an upper guide seat 1-5, a central rod 1-6, a connecting cap 1- 7. Vertical hole pressure sensor 1-11, lower guide seat 1-12, frictionless diaphragm 1-13, inner ring 1-16, outer ring 1-18, stainless steel cylinder 1-19, lateral hole pressure sensor 1- 20. Annular permeable stone 1-21 and clay plate 1-22;

[0047] The plexiglass cylinder wall 1-2 is fixedly connected between the upper cover 1-1 and the base 1-3, the stainless steel cylinder 1-19 is located inside the plexiglass cylinder wall 1-2, and the stainless steel cylinder 1-1...

Embodiment 2

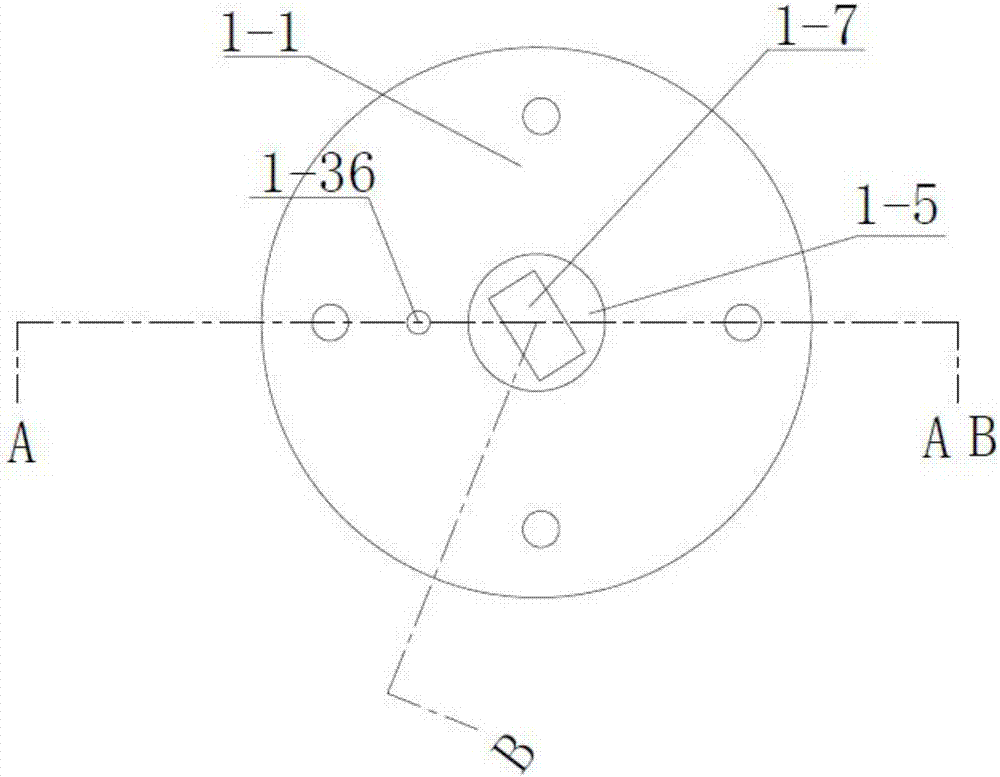

[0065] Such as Figure 6 As shown, the side wall of the frictionless diaphragm 1-13 adopts a wave-shaped structure. During the vertical pressurization process, the airless water in the frictionless diaphragm 1-13 exerts force on the upper section ab and the lower section bc of the wave structure respectively. N 上 and N 下 , and under the same vertical force during the test, the vertical force N of the upper section ab and the lower section bc of the wave structure 上1 and N 下1 are equal in size and opposite in direction, which effectively reduces the horizontal force N on the upper section ab and lower section bc of the wave structure 上2 and N 下2 The effect on the expansion and deformation of the side wall of the frictionless diaphragm 1-13 makes the contact between the frictionless diaphragm 1-13 and the stainless steel cylinder 1-19 change from surface contact to point contact (such as point a), so during the pressurization process, The frictional force between the fricti...

Embodiment 3

[0067] The operation method of the temperature-suction-permeation-stress coupling multifunctional consolidation system described in the present invention is:

[0068] When carrying out the saturation consolidation test, close the fifth high-pressure ball valve 1-34, the second high-pressure ball valve 1-29, and the first high-pressure ball valve 1-30, and then the saturation consolidation test can be carried out;

[0069] When performing the unsaturated consolidation test, close the second high-pressure ball valve 1-29, the third high-pressure ball valve 1-26 and the fourth high-pressure ball valve 1-35, and then the unsaturated consolidation test can be performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com