Intelligent segmental temperature control system of wind power blade die

A segmented temperature control and wind power blade technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of shortening blade pre-curing time, high energy consumption, poor quality stability, etc., to achieve excellent quality, glue Good bonding strength and uniform curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

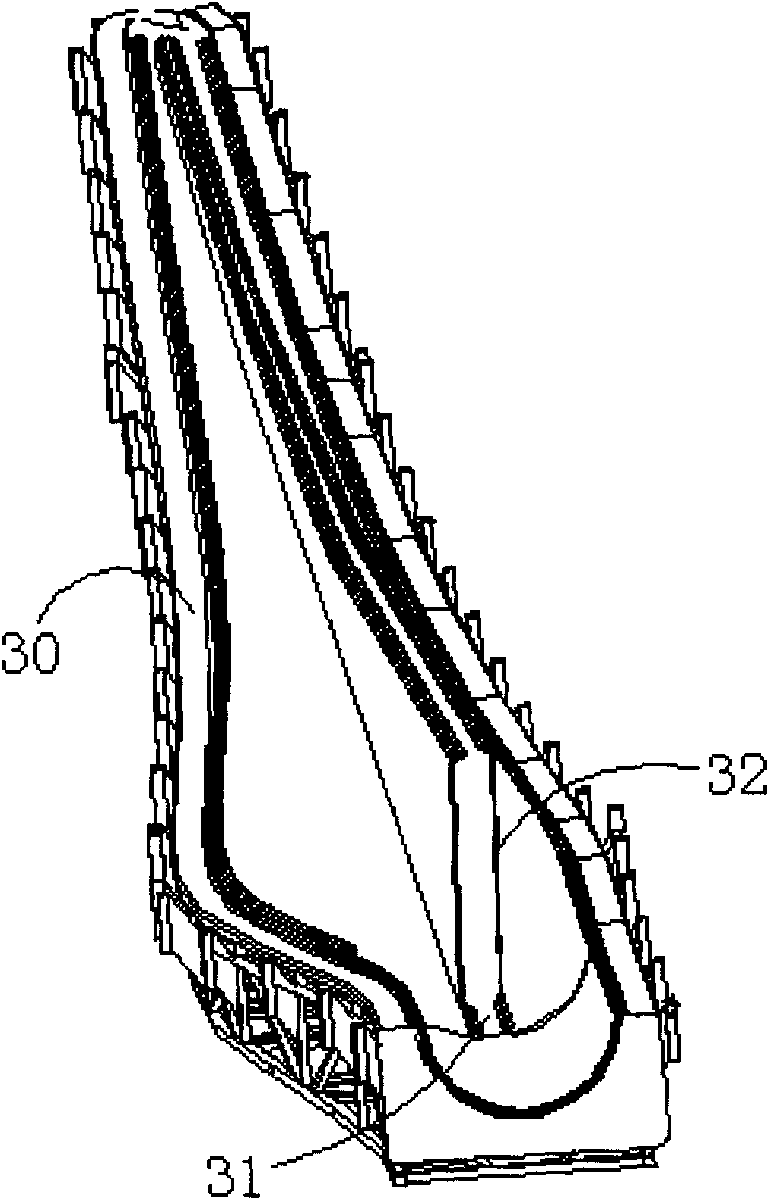

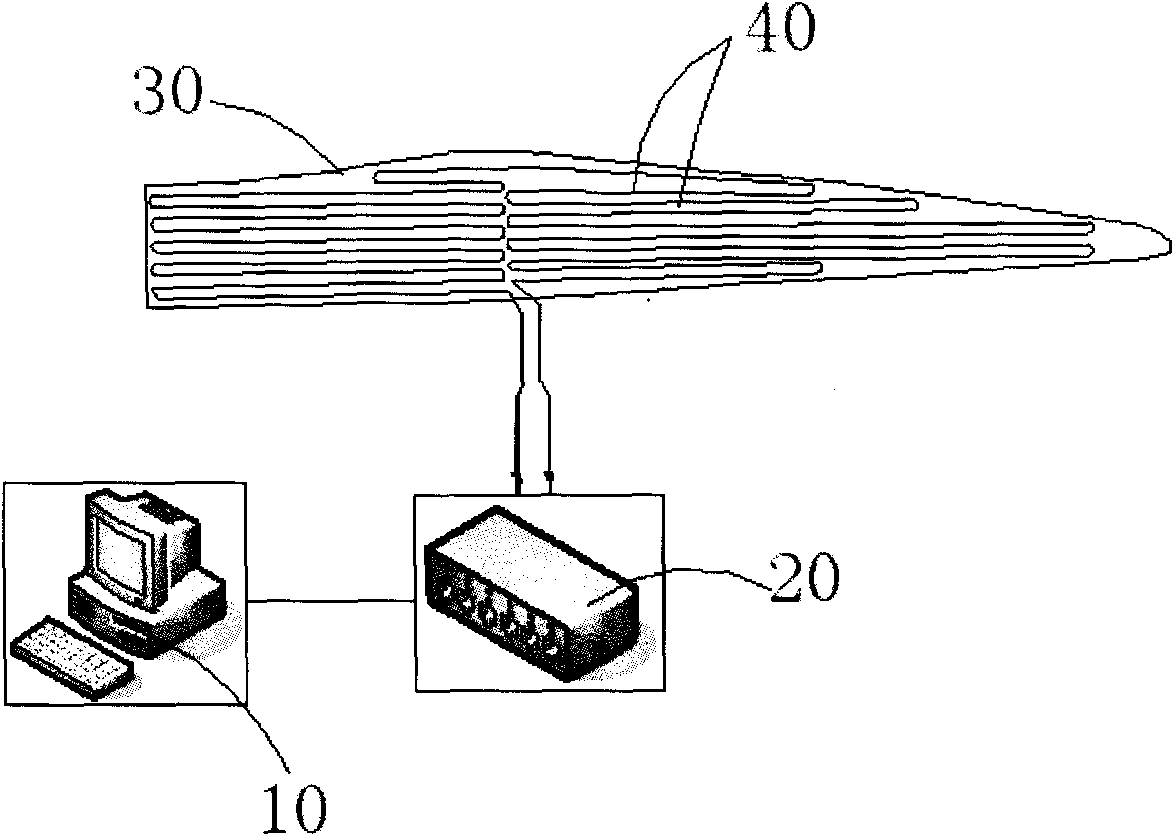

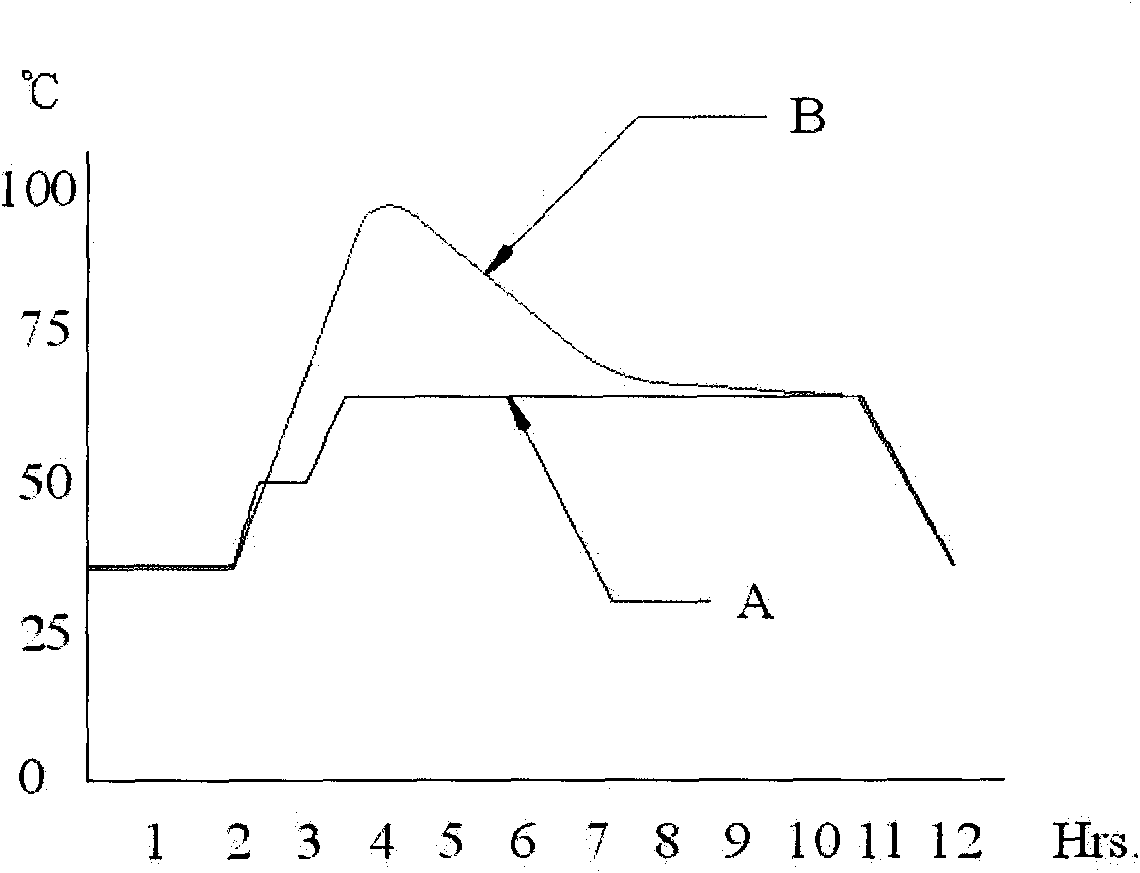

[0032] Figure 4 to Figure 10 Reference numerals: computer 10, mold temperature control device 20 (temperature control machine A21, temperature control machine B23, temperature control machine C25), leaf shell mold 30, mold temperature measurement unit 35, temperature control pipeline 40 (temperature control pipeline A Zone 42, temperature control pipeline B zone 44, temperature control pipeline C zone 46), blade shell 50, blade shell temperature measurement unit 55, blade shell hardness measurement unit 60;

[0033] see Figure 4 As shown, it is a schematic diagram of the hardware structure of the intelligent segmented temperature control system of the wind power blade mold of the present invention; the intelligent segmented temperature control system of the wind power blade mold mentioned in this creation is applied to the wind turbine blade shell 50 or related For the pre-curing process of components (such as the main composite layer (Spar Cap or Girder) and the main suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com