Patents

Literature

32results about How to "Suppress high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

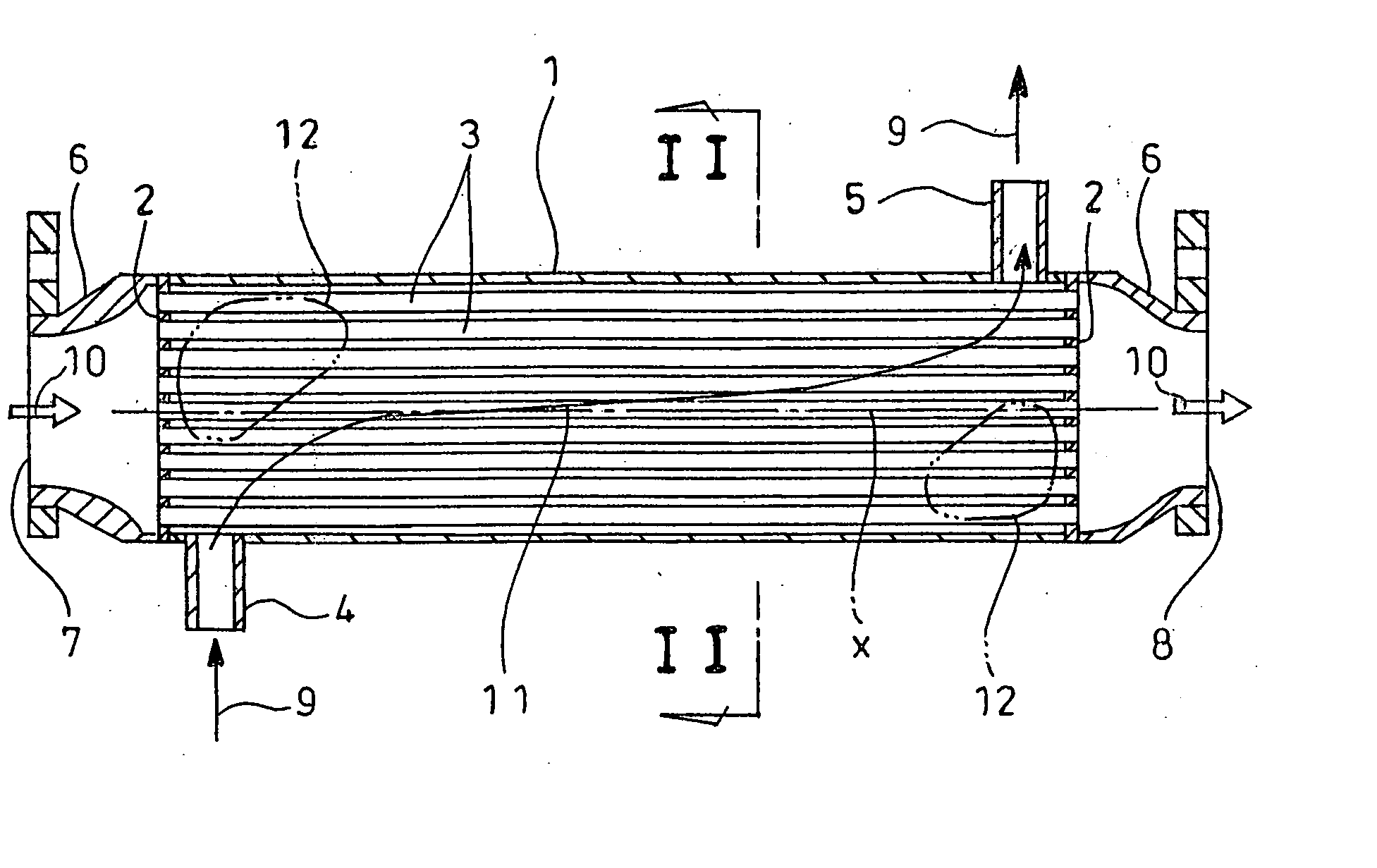

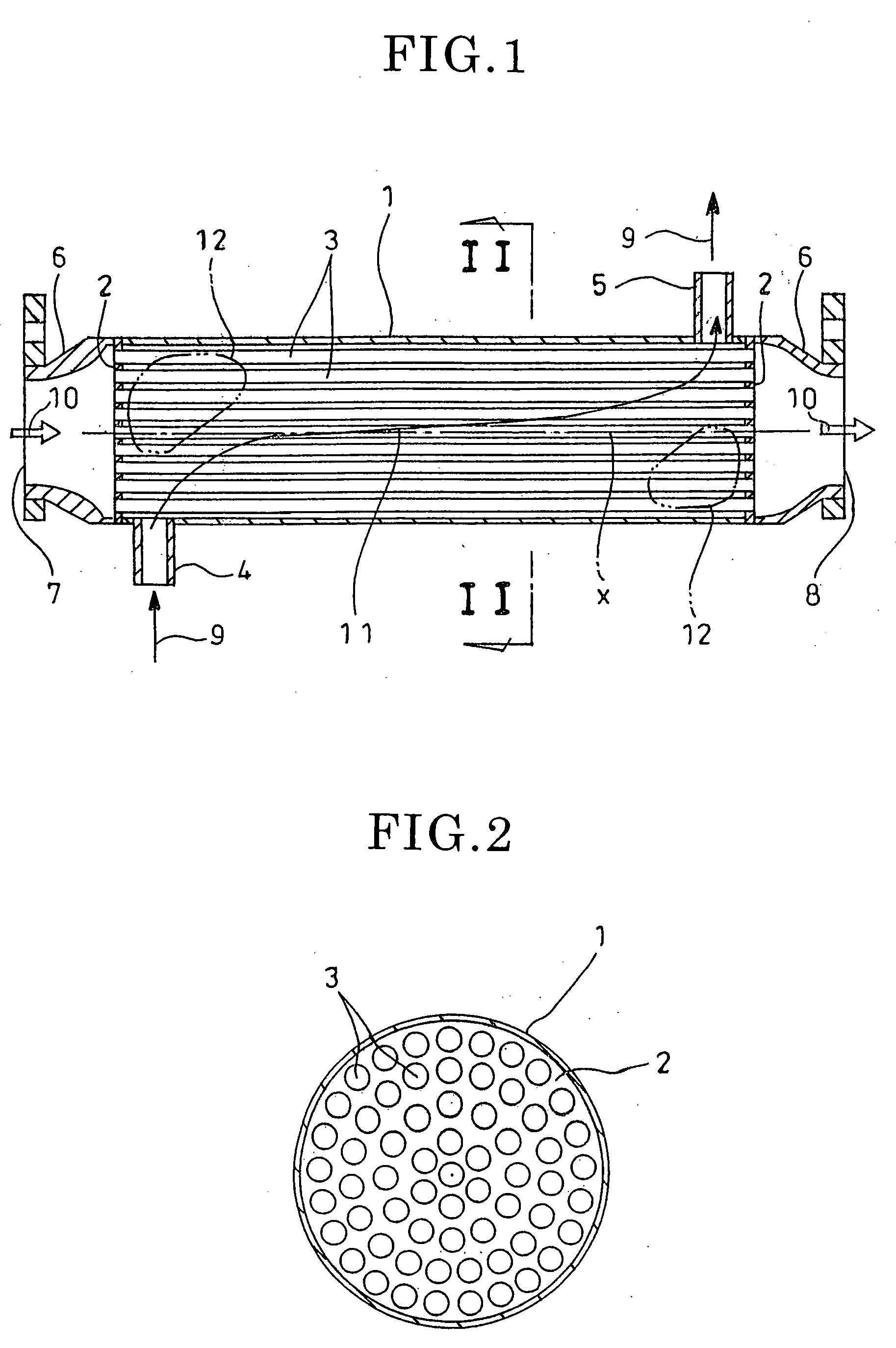

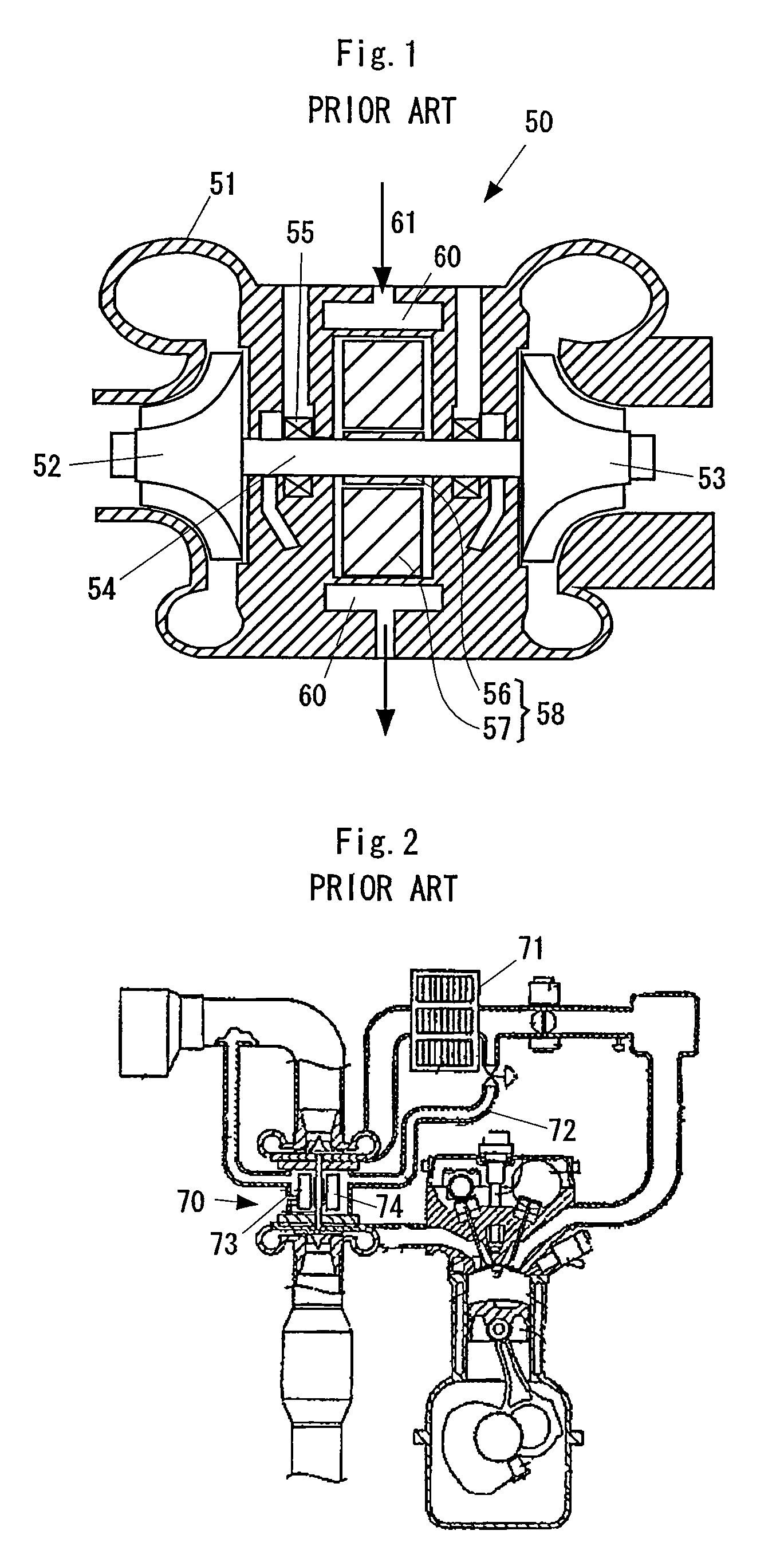

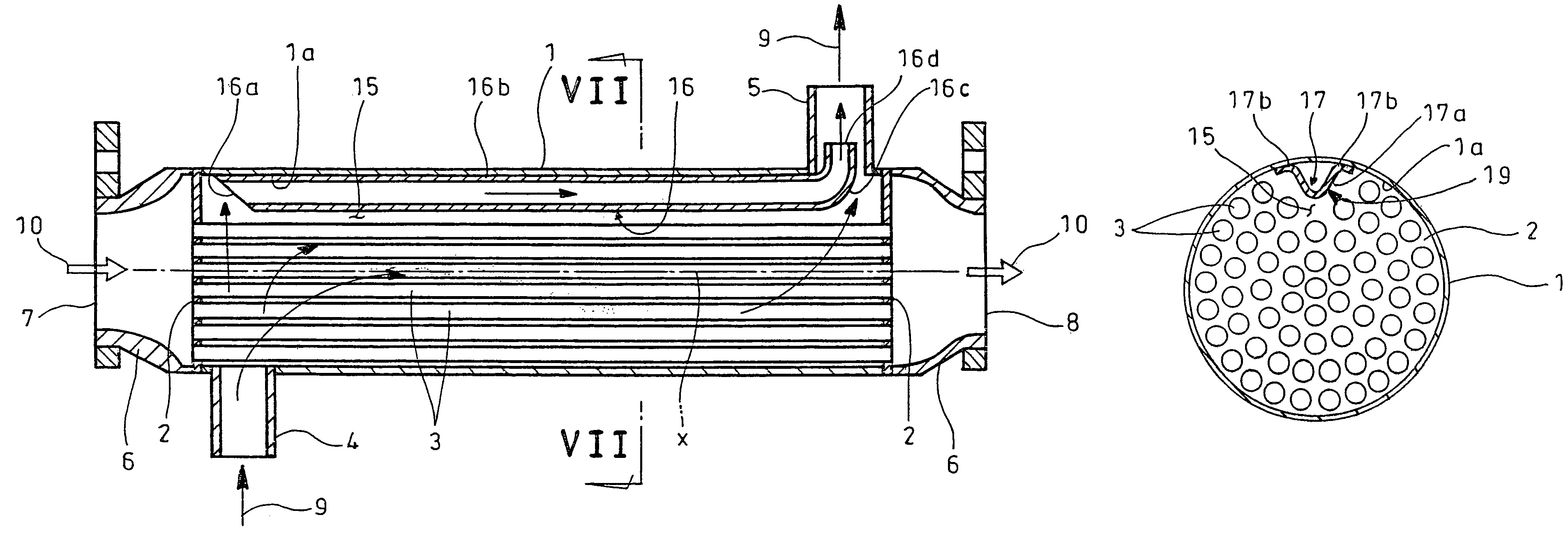

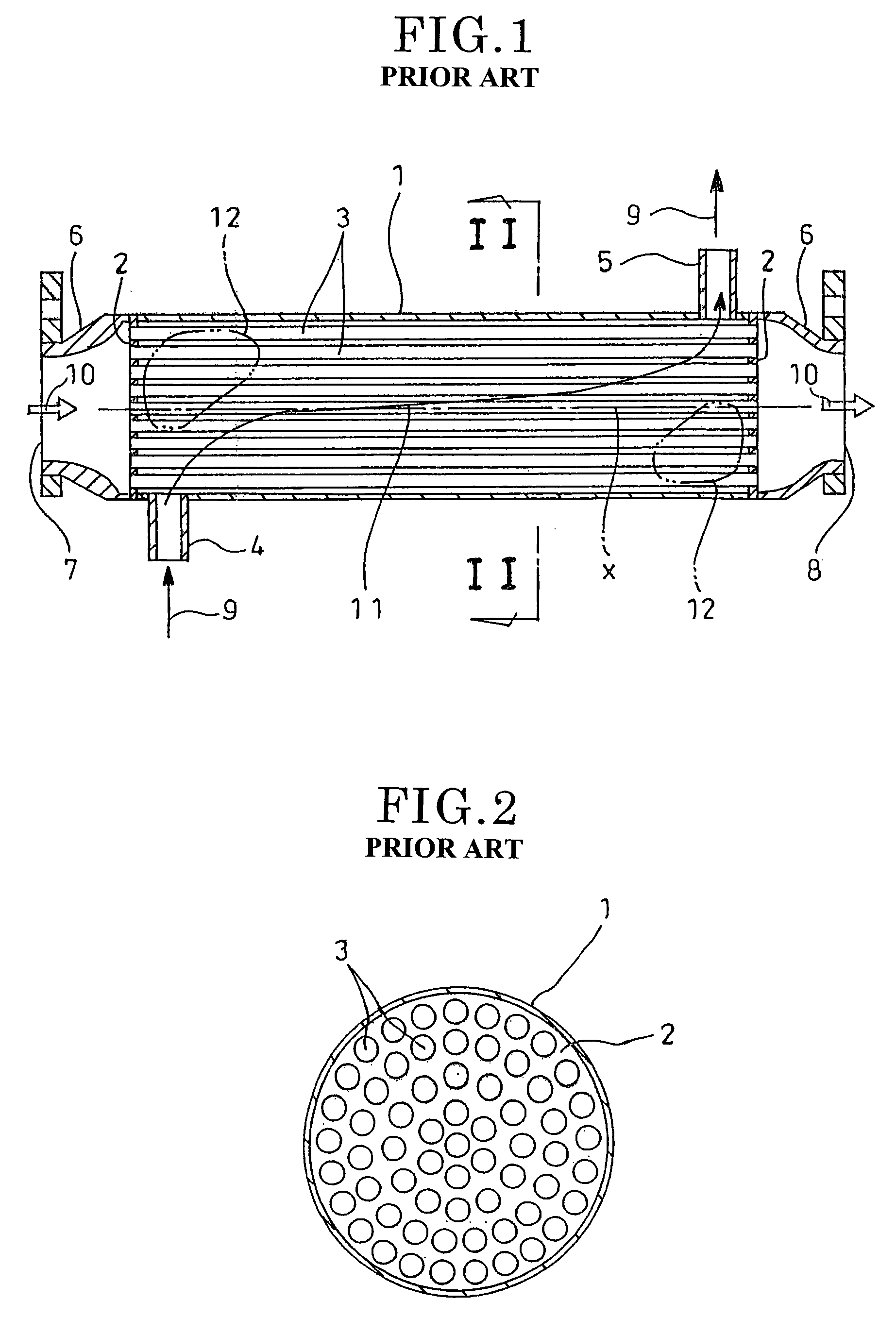

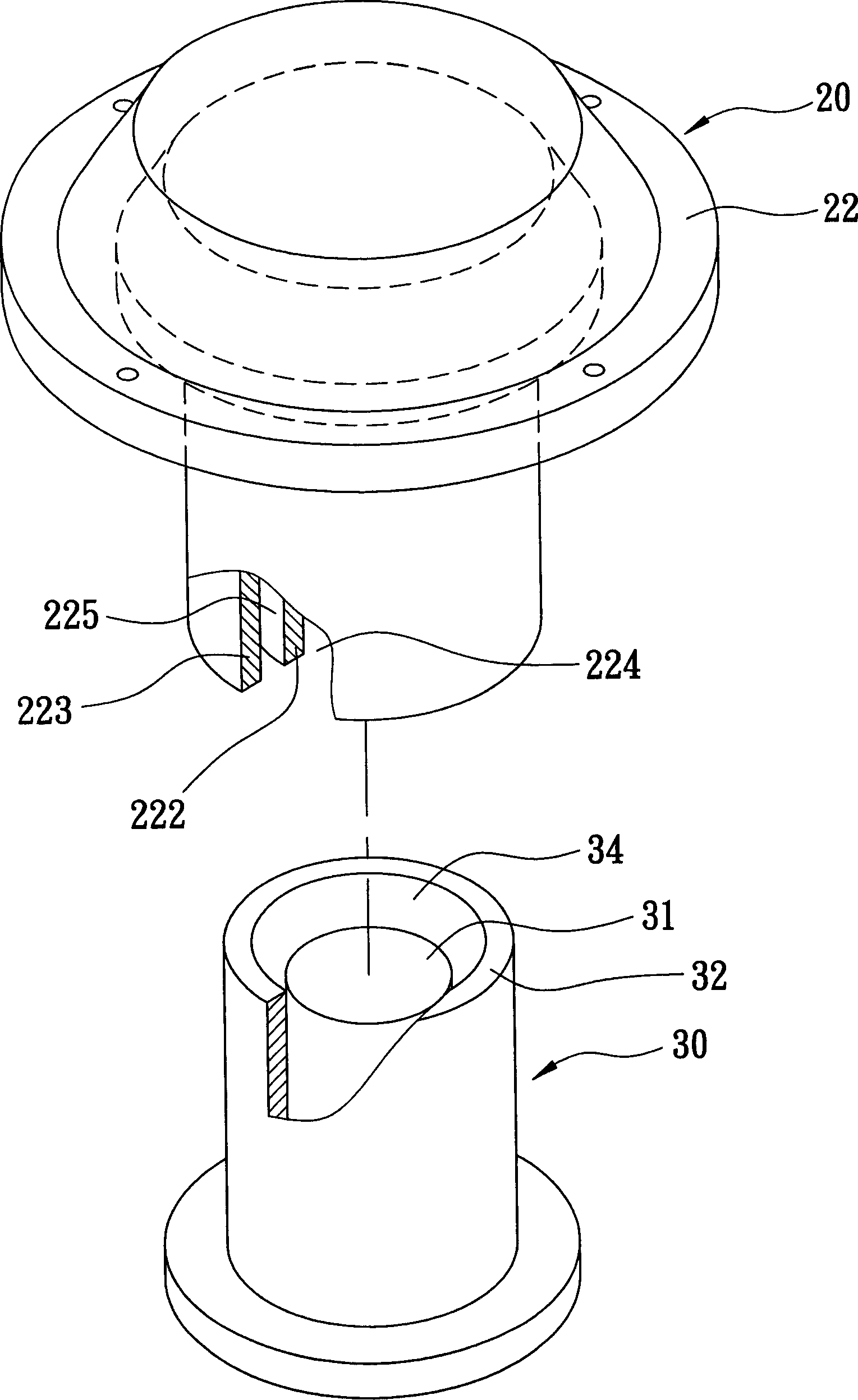

Egr cooler

InactiveUS20060090880A1Improve cooling effectImprove heat transfer efficiencyAir-treating devicesInternal combustion piston enginesDiesel engineChiller

An EGR cooler including tubes and a shell enclosing the tubes. Cooling water is supplied into and discharged from the shell. Exhaust gas is guided from a diesel engine into the tubes for thermal exchange of the exhaust gas with the cooling water. A bypass flow path for guiding the cooling water is constituted within the shell so as to prevent stagnation of the cooling water in the shell.

Owner:HINO MOTORS LTD +2

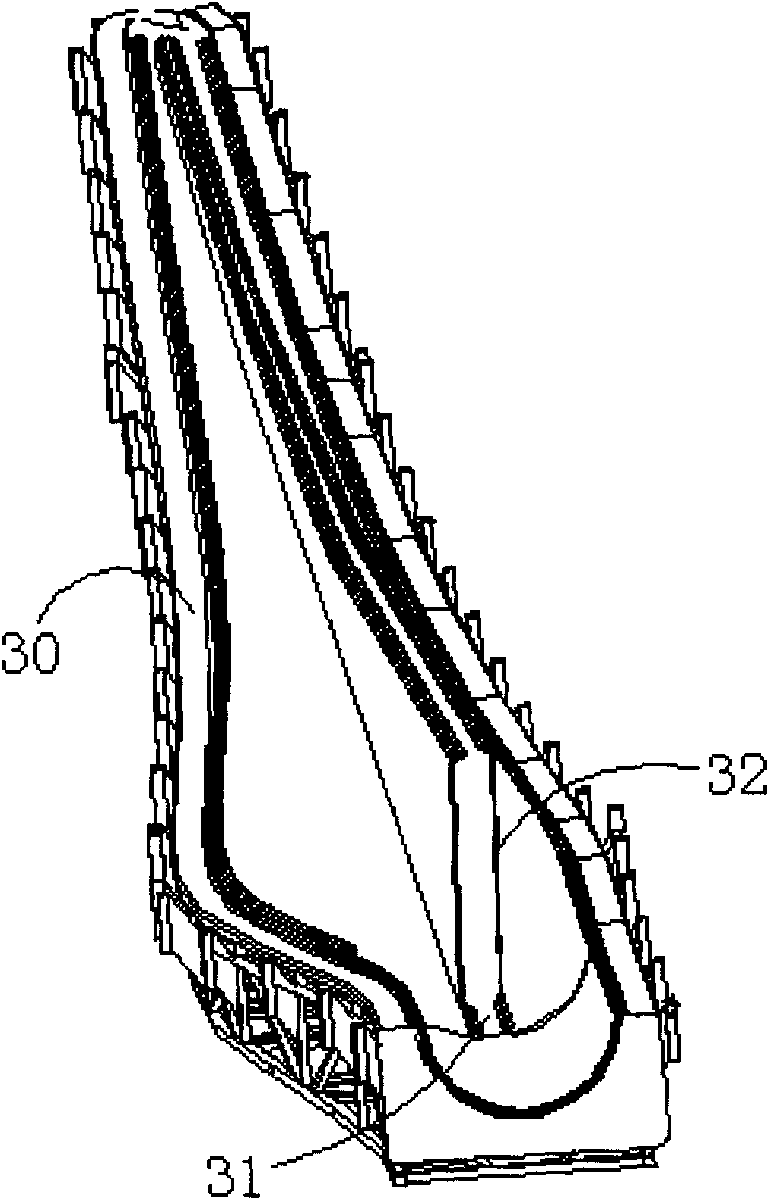

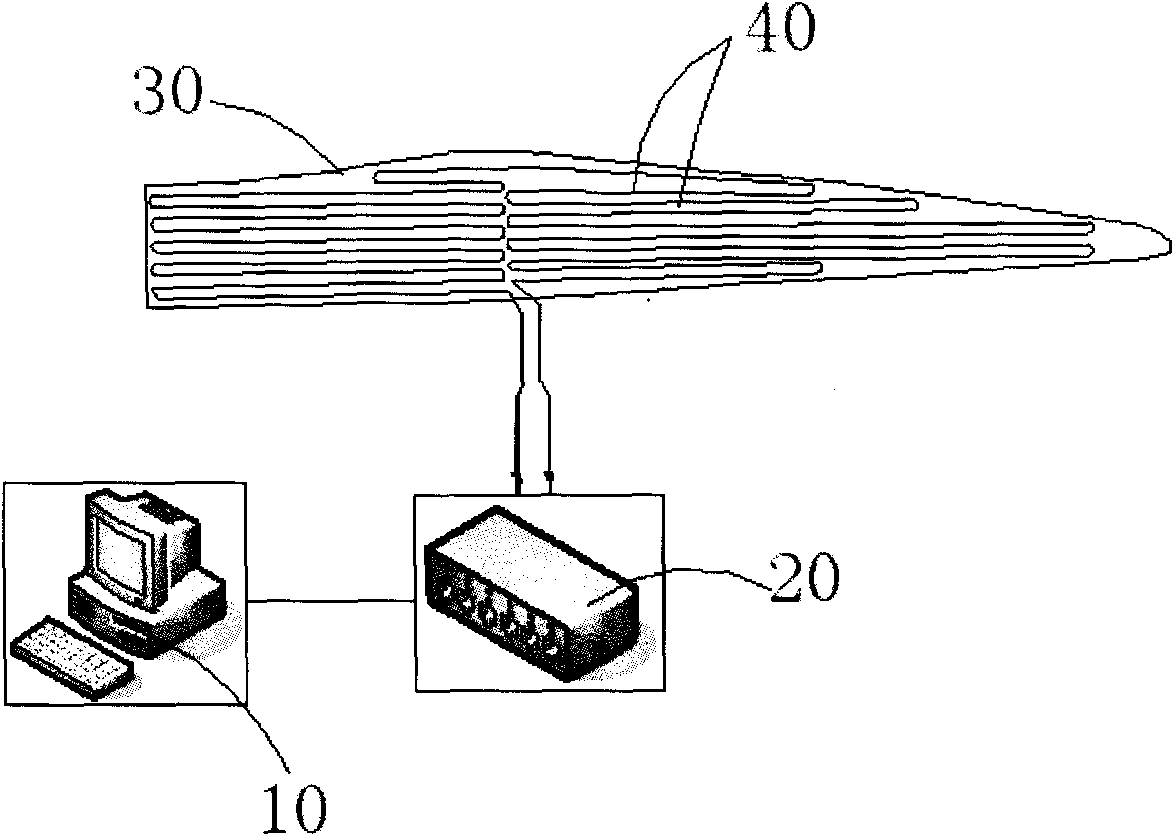

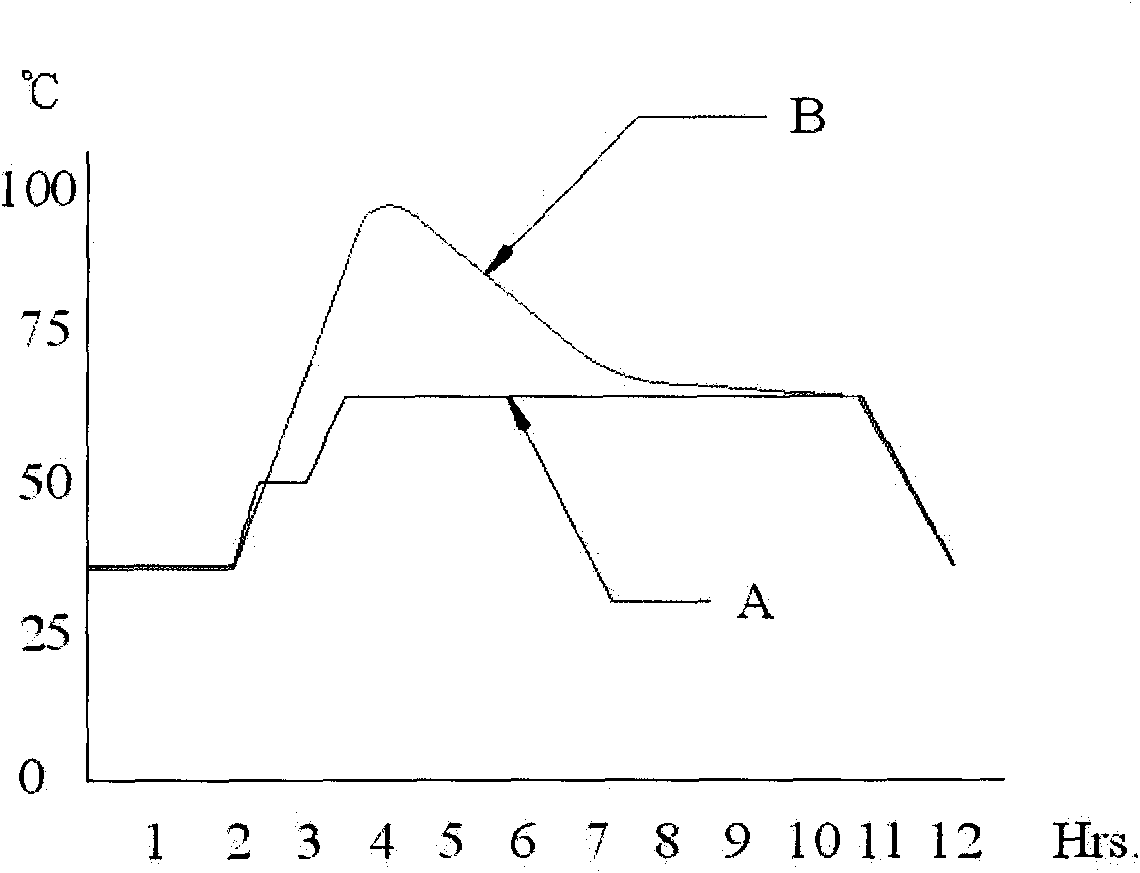

Intelligent segmental temperature control system of wind power blade die

The invention relates to an intelligent segmental temperature control system of a wind power blade die, which is provided based on the technical theory that segmental temperature control is bound to be carried out based on the differences on the formed region thickness of a designed blade structure and the energy-saving purpose can be achieved by lowering the dependence on external heating in a curing manufacturing procedure by utilizing the reaction exothermic character of a matrix material. To achieve the purpose, the invention adopts the technical measures of the construction of a die segmental temperature control pipeline, which ensures that each temperature segment can be heated or cooled independently based on requirements on thermal energy in the curing manufacturing procedure; the establishment of an intelligent temperature control system, wherein temperature and hardness data of the die and a blade shell can be captured to judge whether heating setting, exothermic peak initiating temperature and the states of completion degree, gel curing degree and the like are completed or conform to design values; and antecedent technical measures, wherein energy consumption is saved by utilizing the reaction heat of materials per se to heat and reaction and temperature control are combined to match the design of a temperature curve, which are helpful for obtaining the blades with uniform curing and excellent quality and can improve the production efficiency as a characteristic.

Owner:上海力仓实业有限公司

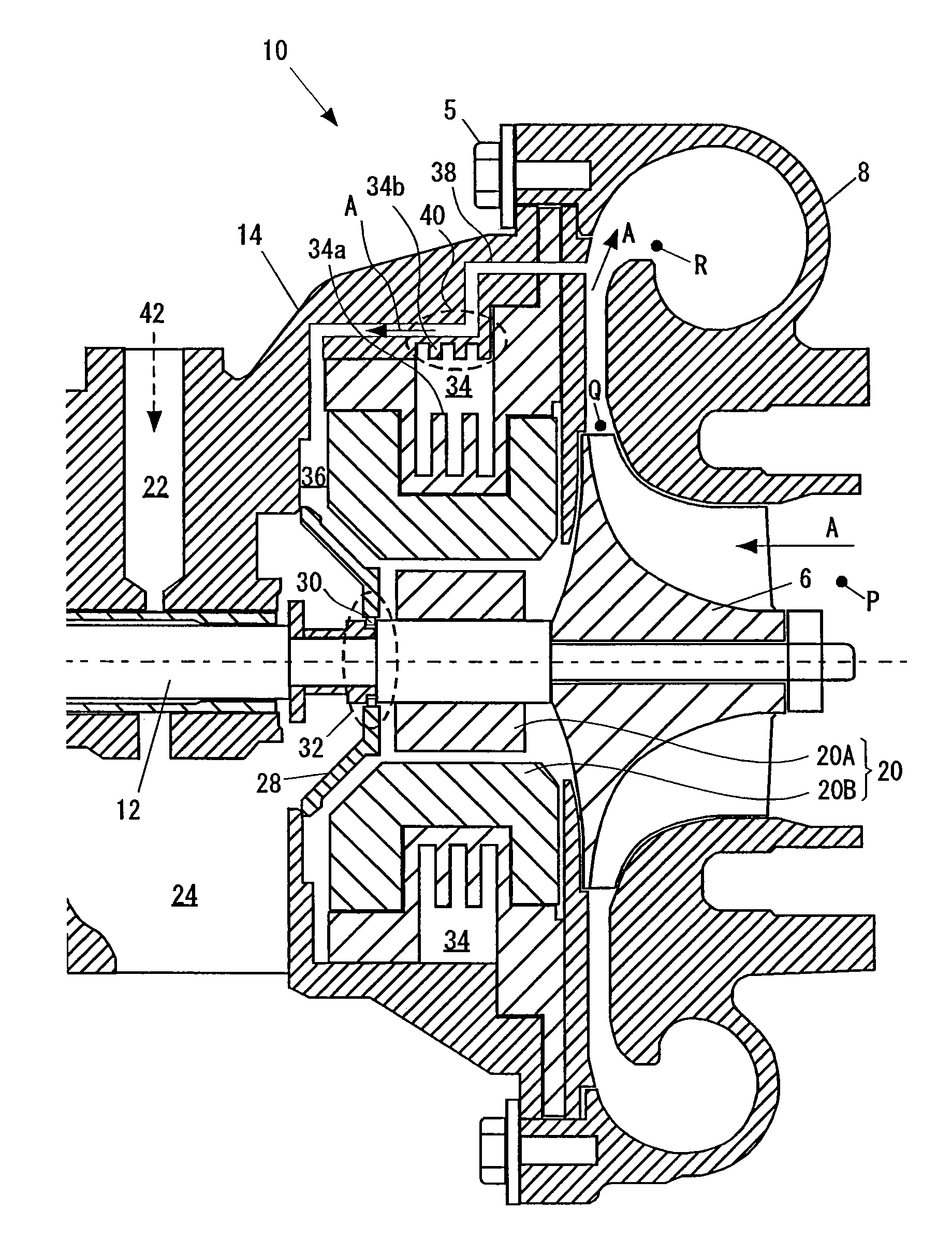

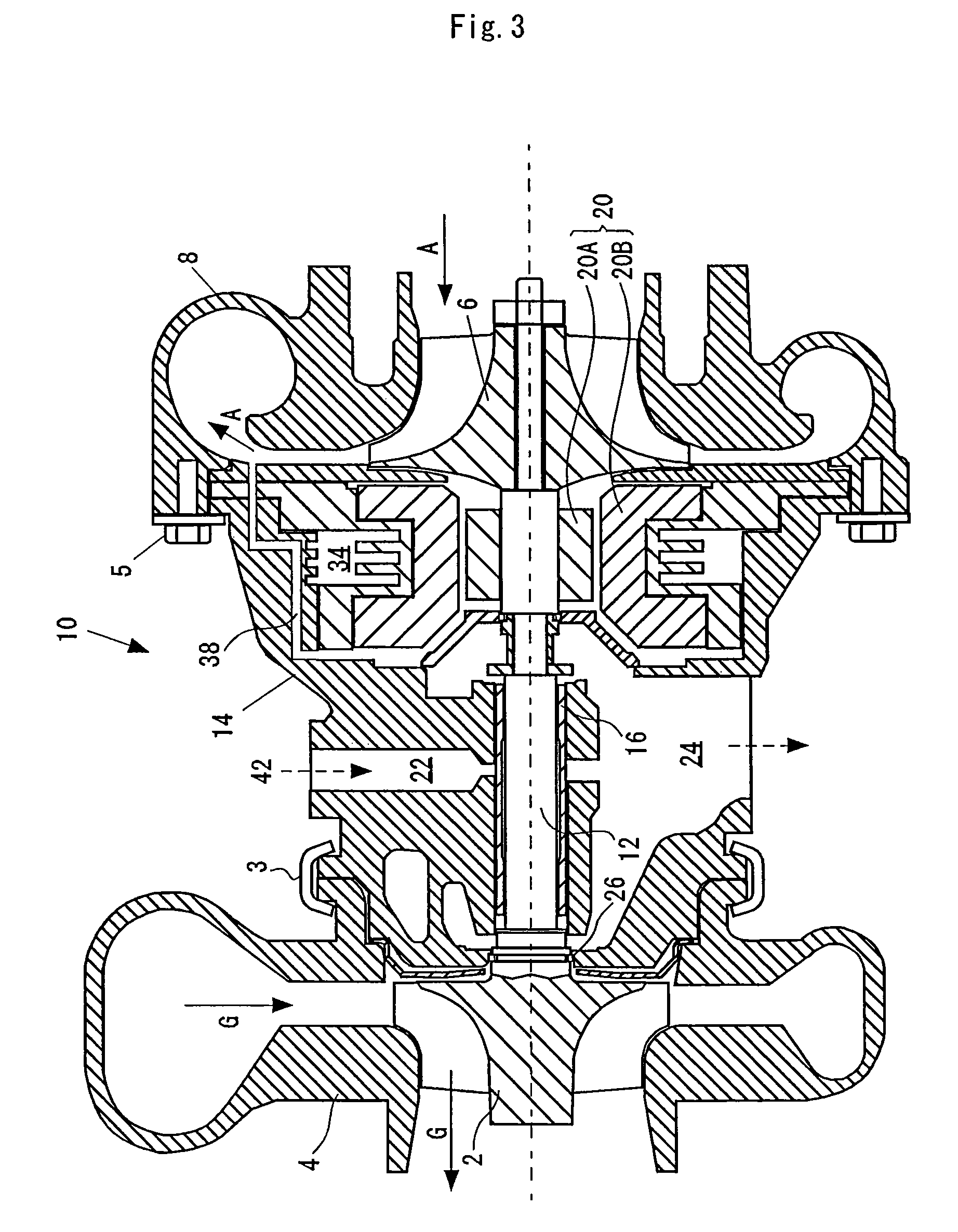

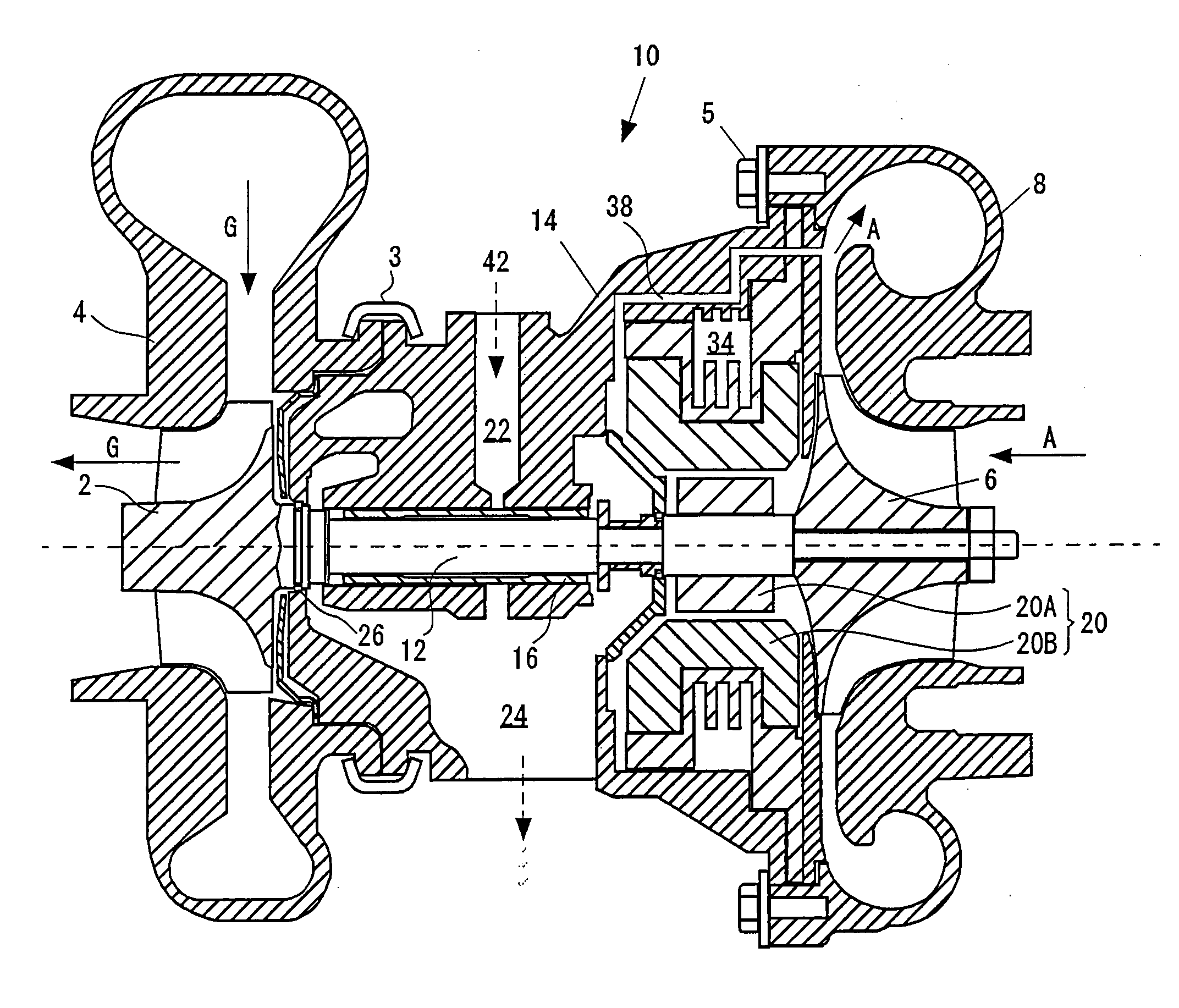

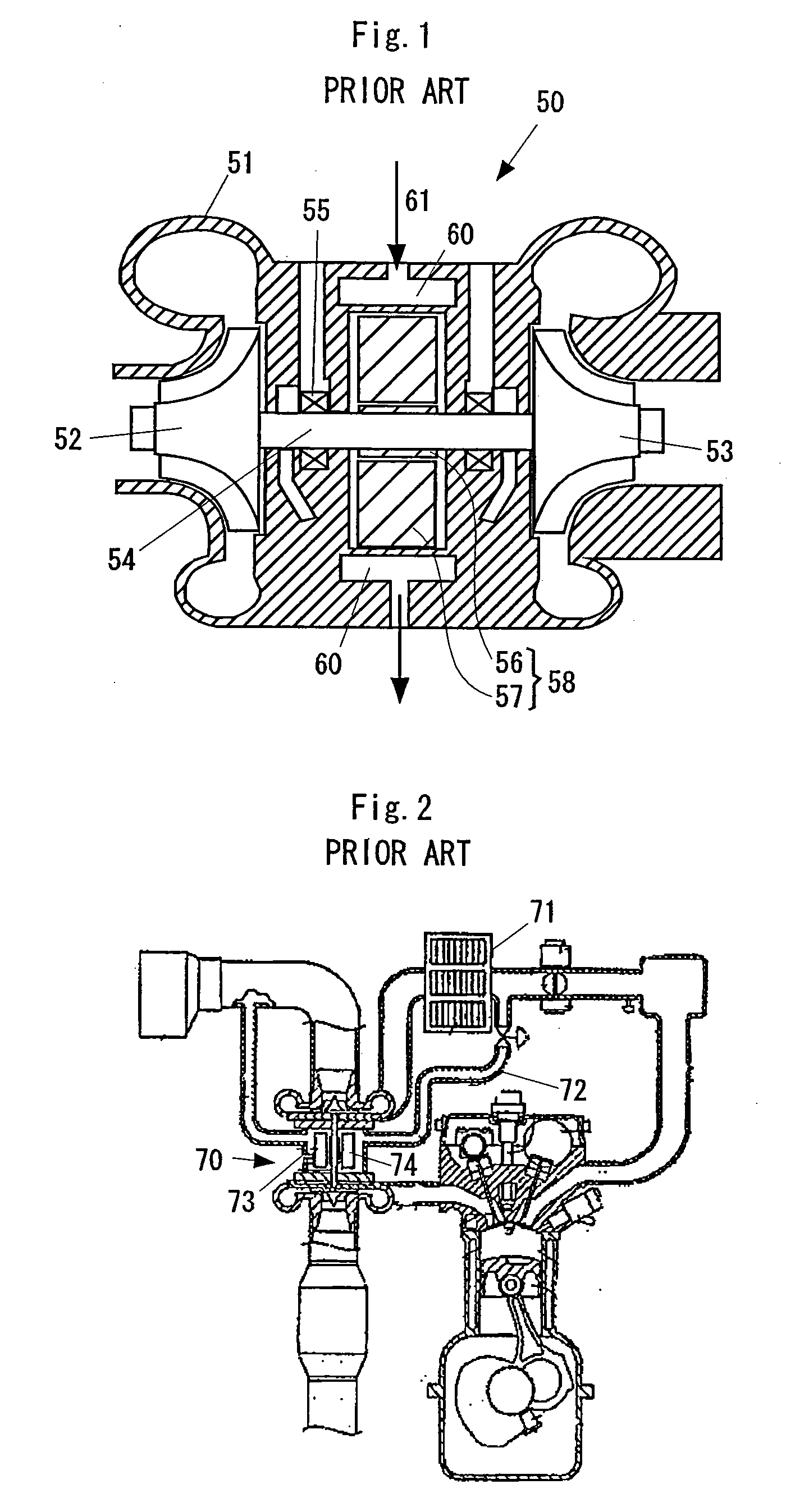

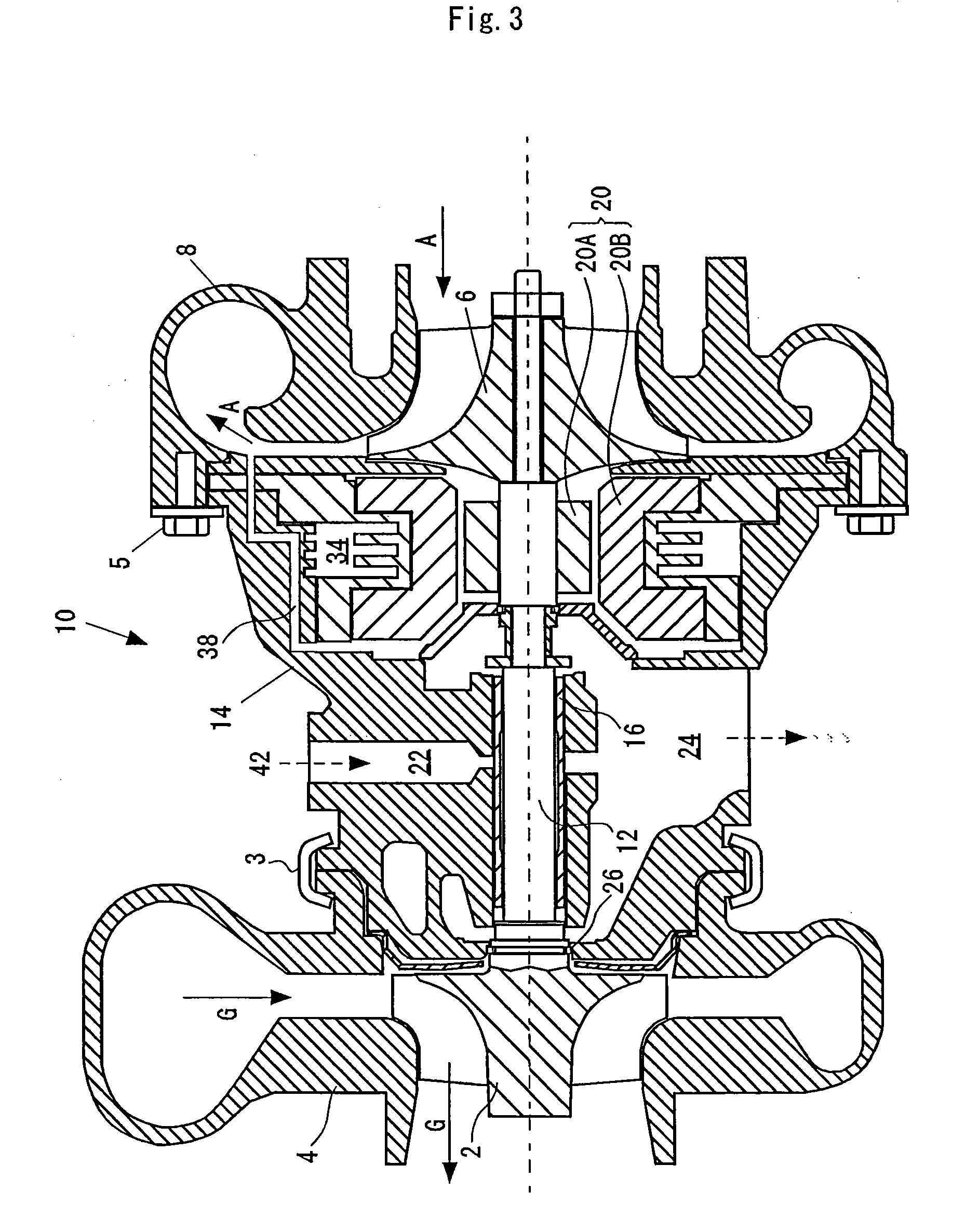

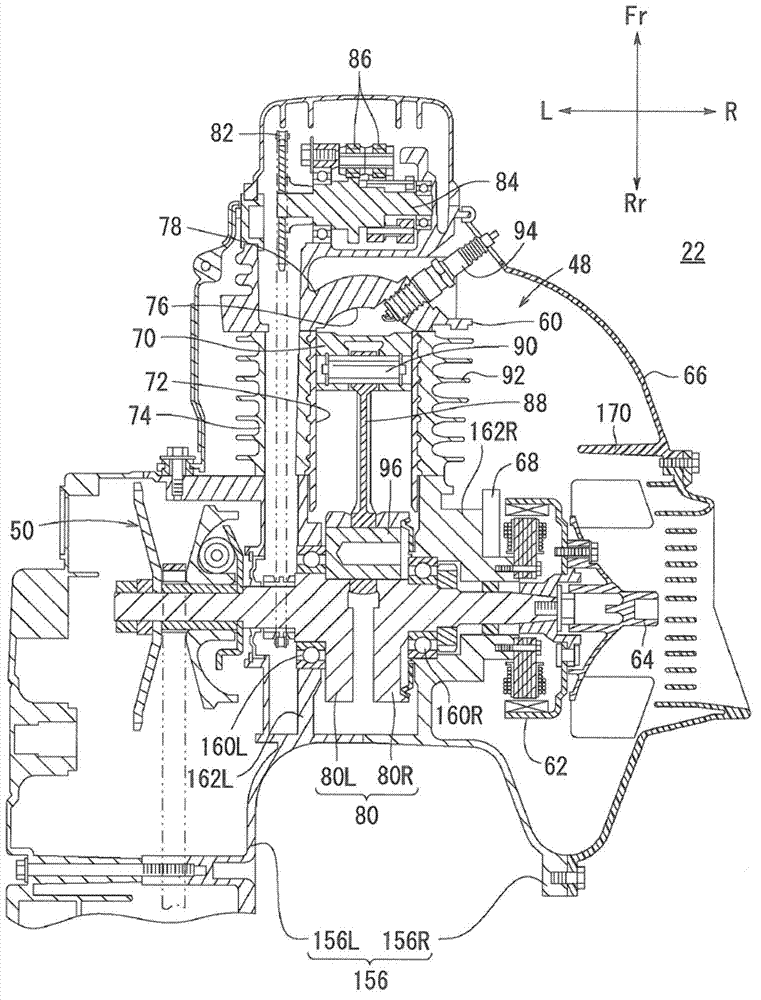

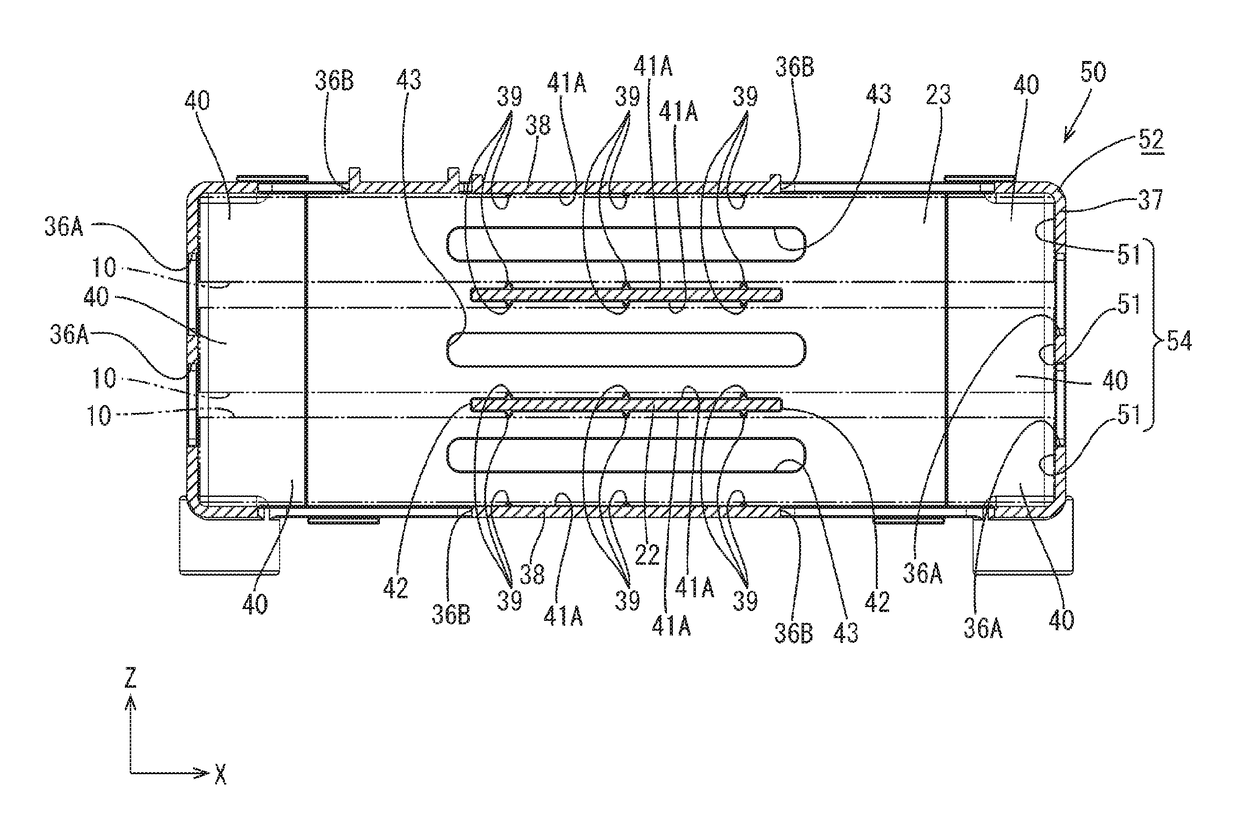

Supercharger with electric motor

ActiveUS7530230B2Suppress high temperatureEffectively cool a stator and a rotorInternal combustion piston enginesCircumferential flow pumpsCooling fluidSupercharger

In a supercharger (10) with an electric motor in accordance with the invention, an inner side of the center housing (10) is provided with an air introduction path (38) introducing a part of a compressed air within the compressor housing (8) to the electric motor (20), and a cooling structure portion (40) cooling the air flowing through the air introduction path (38). The center housing (14) has a cooling fluid flow path (34) which is formed so as to surround the electric motor (20) and puts a cooling fluid for cooling the electric motor (20) in circulation inside. The cooling structure portion (40) is structured such as to be capable of heat exchanging between the cooling fluid and the air flowing through the air introduction path (38).

Owner:IHI CORP

Supercharger with electric motor

ActiveUS20090056681A1Improve cooling effectGood effectInternal combustion piston enginesCircumferential flow pumpsCooling fluidSupercharger

In a supercharger (10) with an electric motor in accordance with the invention, an inner side of the center housing (10) is provided with an air introduction path (38) introducing a part of a compressed air within the compressor housing (8) to the electric motor (20), and a cooling structure portion (40) cooling the air flowing through the air introduction path (38). The center housing (14) has a cooling fluid flow path (34) which is formed so as to surround the electric motor (20) and puts a cooling fluid for cooling the electric motor (20) in circulation inside. The cooling structure portion (40) is structured such as to be capable of heat exchanging between the cooling fluid and the air flowing through the air introduction path (38).

Owner:IHI CORP

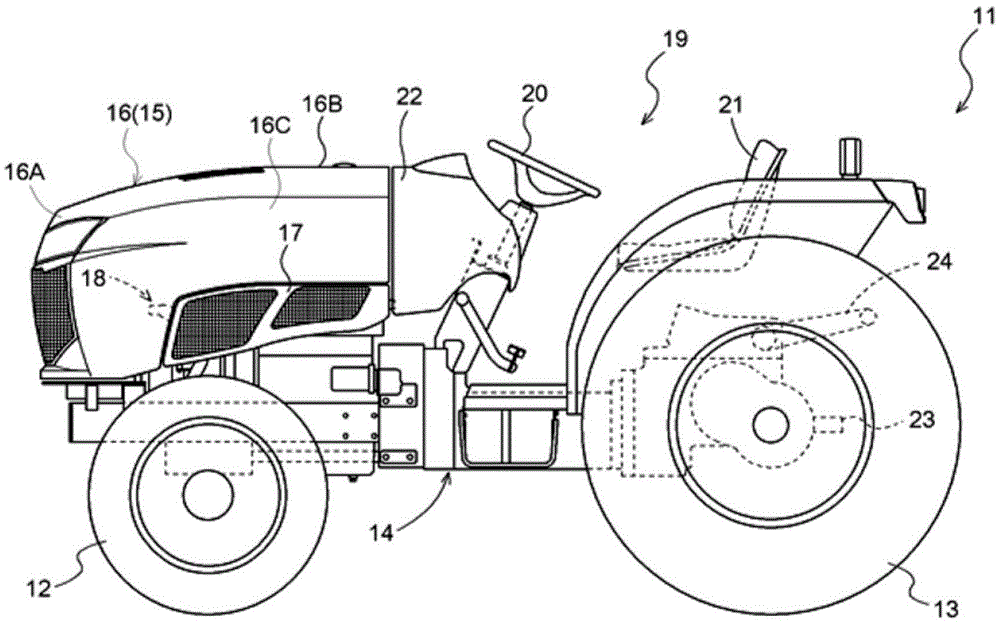

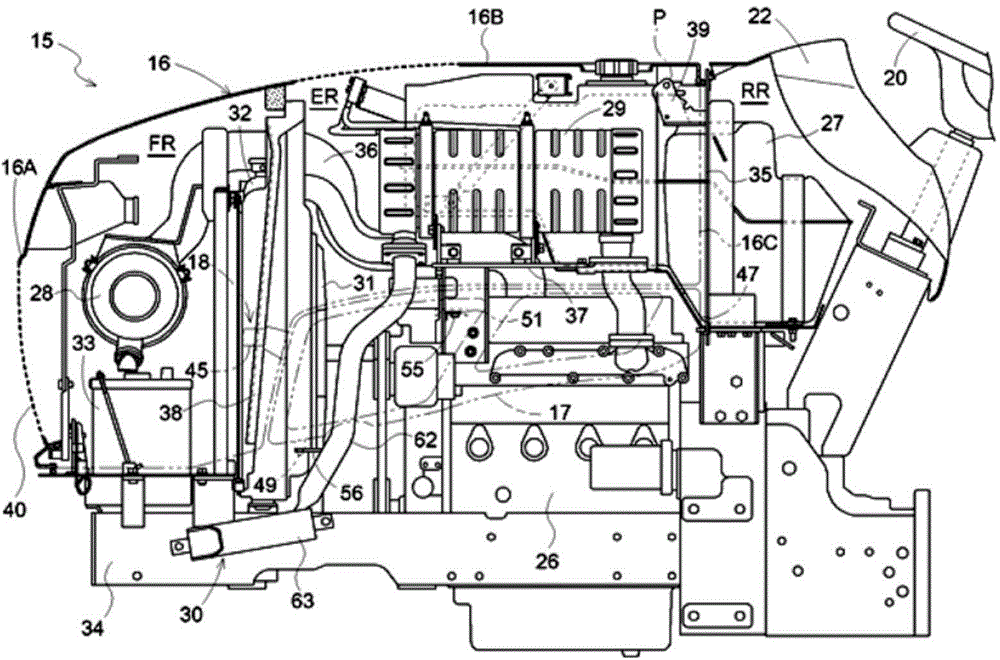

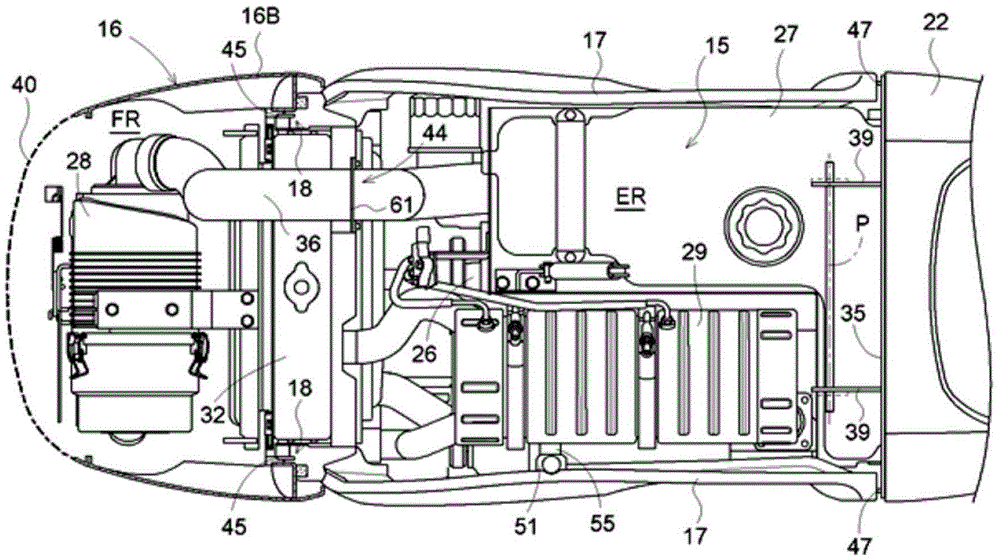

Cover Installation Structure Of Working Vehicle And Air Exhausting Device Of The Working Vehicle

ActiveCN104029738AReduce exhaust temperatureSuppress high temperatureSuperstructure subunitsVehiclesMechanical engineeringEngineering

A working vehicle includes a traveling machine assembly, a drive unit, a bonnet configured to cover the drive unit, and a cover provided below the bonnet and configured to be removably attached to the traveling machine assembly, including a main body portion extending in a longitudinal direction of the traveling machine assembly, a first male engagement portion provided at a front end portion of the main body portion, a second male engagement portion provided at a rear end portion of the main body portion, and a third male engagement portion provided at a lower end portion of the main body portion.

Owner:KUBOTA CORP

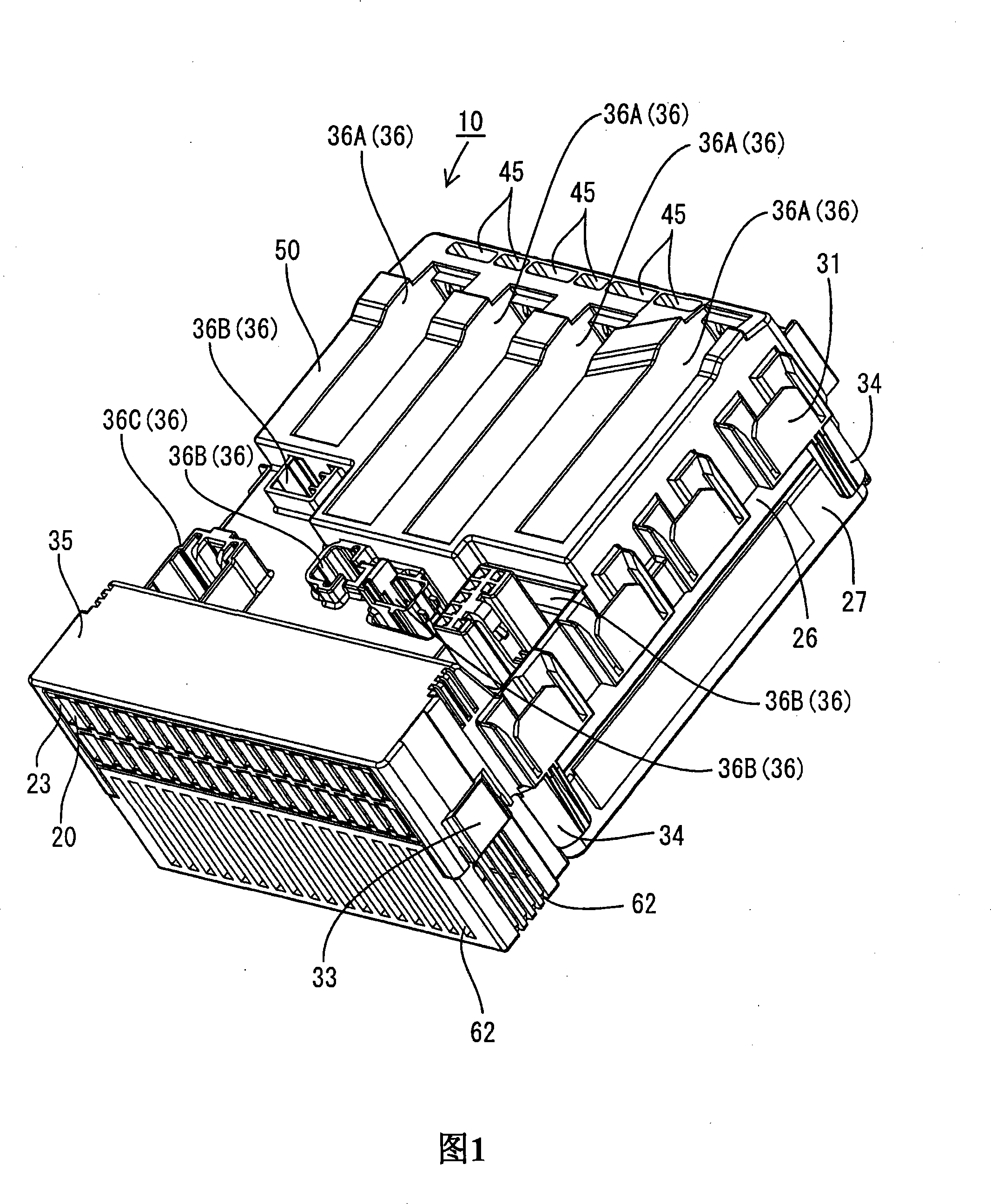

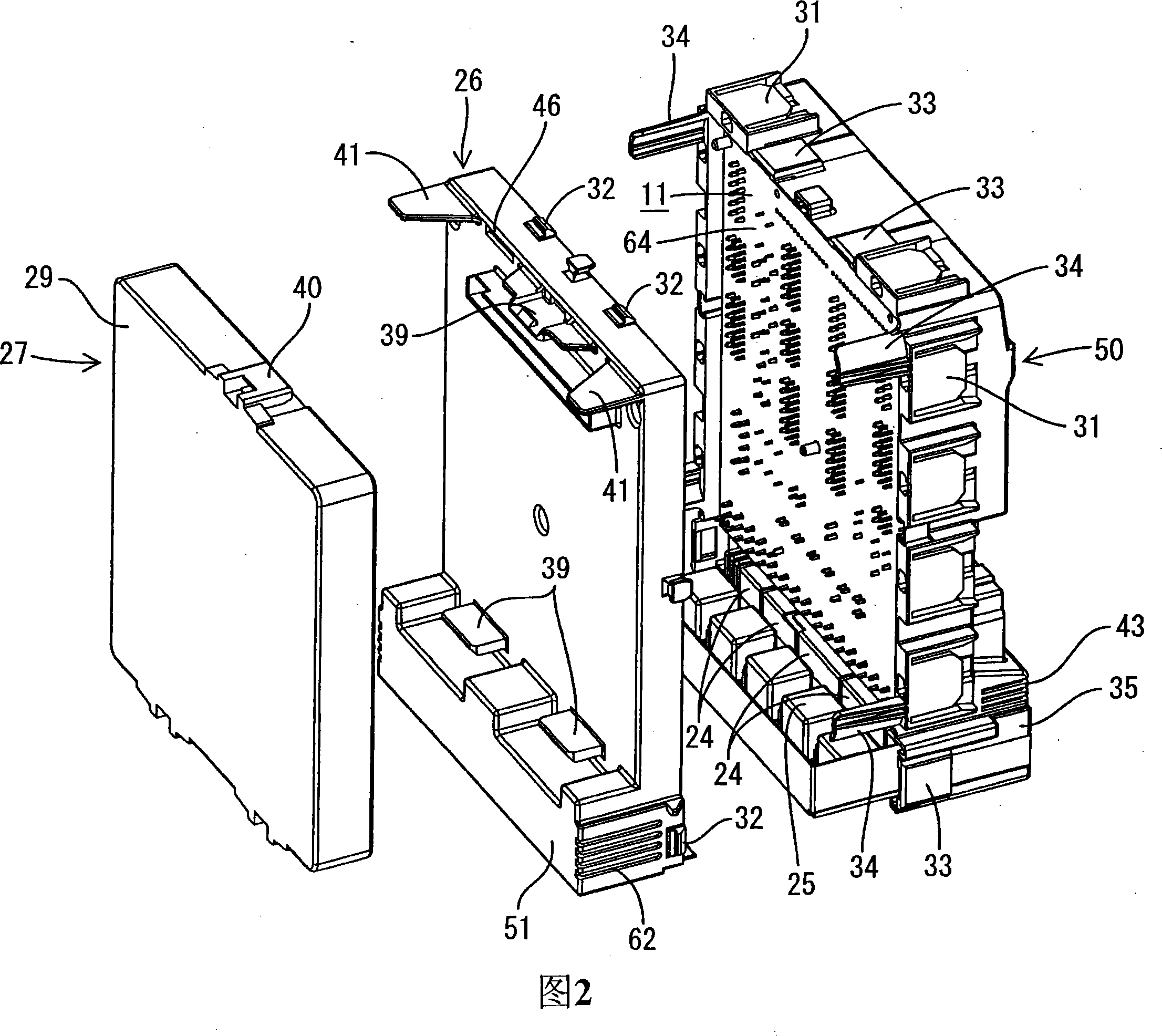

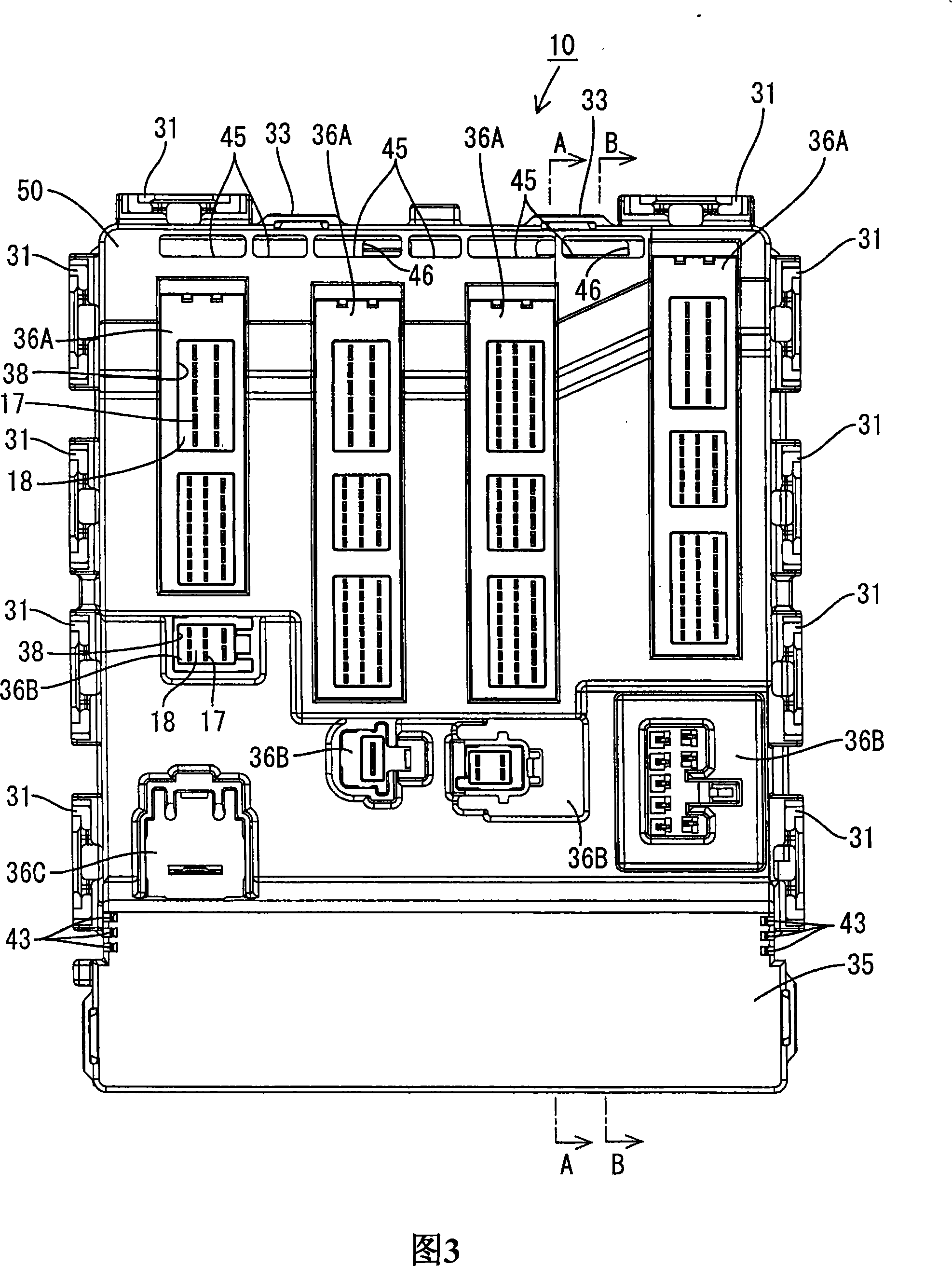

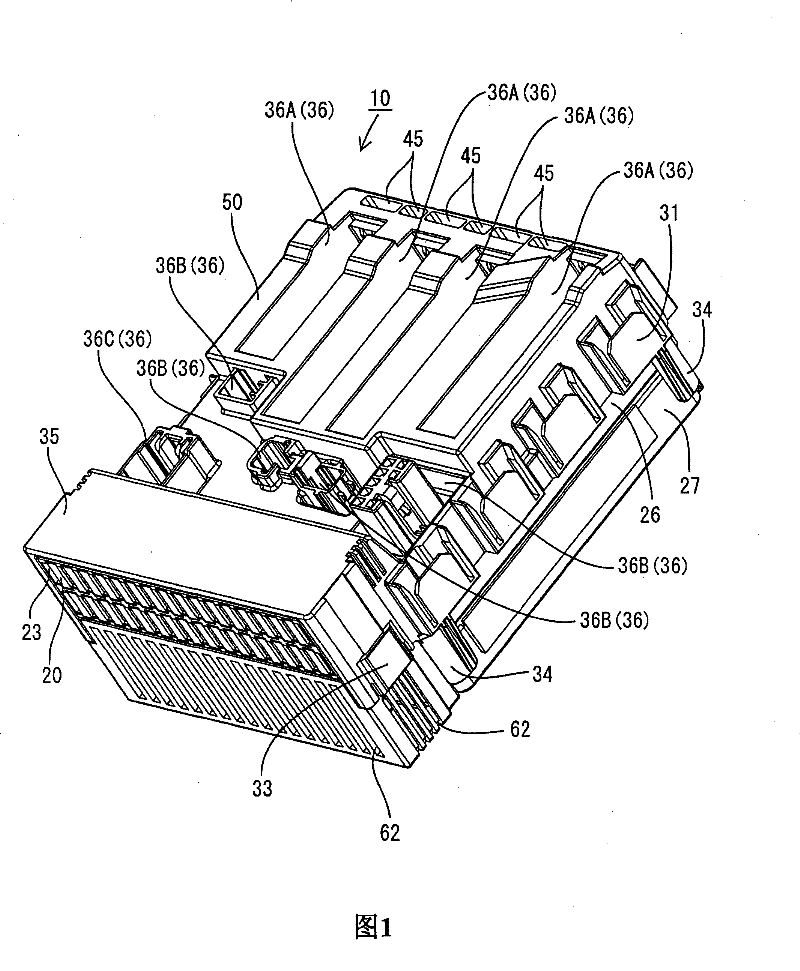

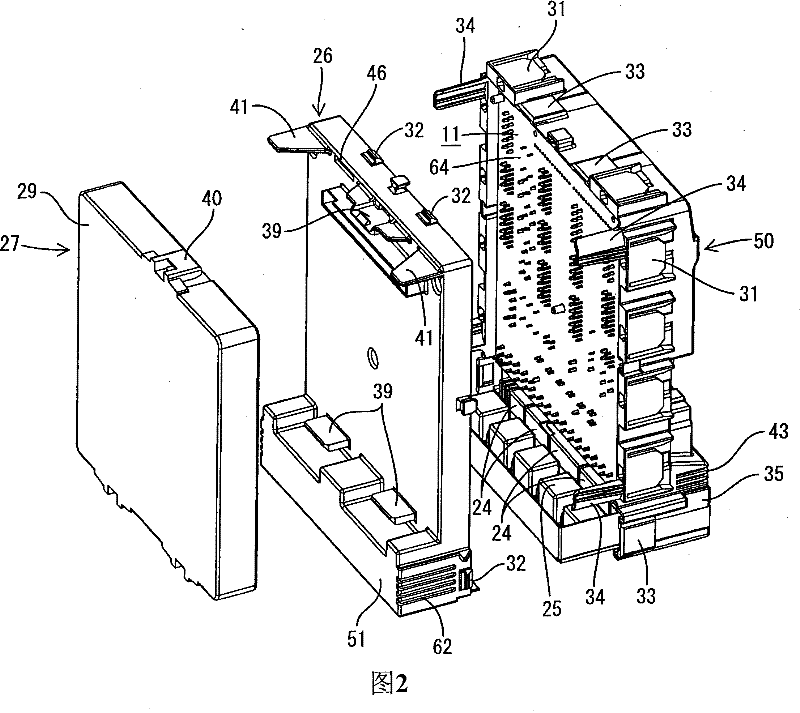

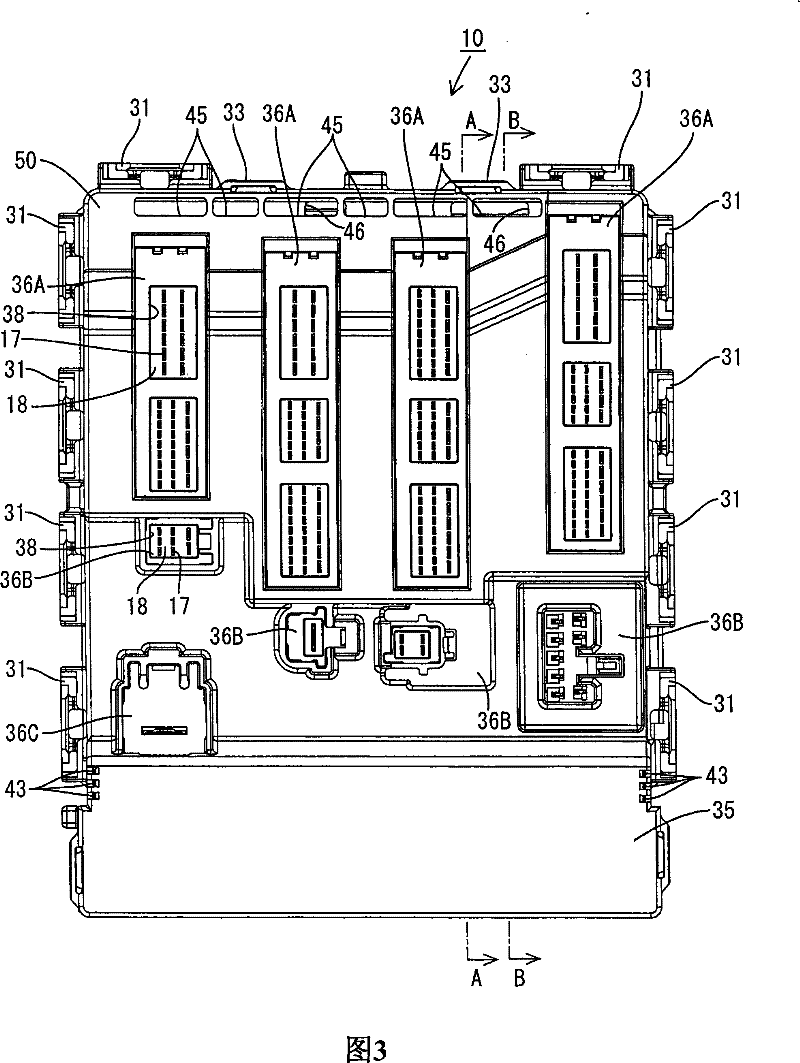

Electric connection box

InactiveCN101188351ASuppress high temperatureCooling/ventilation/heating modificationsElectrical connectionEngineering

An electrical connection box, which includes: a circuit substrate; a plurality of conductive components arranged on the circuit substrate spaced apart from each other and extending in a direction away from the circuit substrate; a housing that connects the circuit The substrate is accommodated inside; the gas passage is formed in the casing, and allows air to circulate in the up and down direction; the air inlet is arranged on the casing and connected with the gas passage; the exhaust port is arranged on the The casing is connected with the gas passage, and is arranged above the air inlet; the part to be cooled is arranged on the conductive component, and is located in the gas passage so that air flows in the conductive part. The parts communicate up and down; and the heating part is connected with the cooled part of the conductive part.

Owner:AUTONETWORKS TECH LTD +2

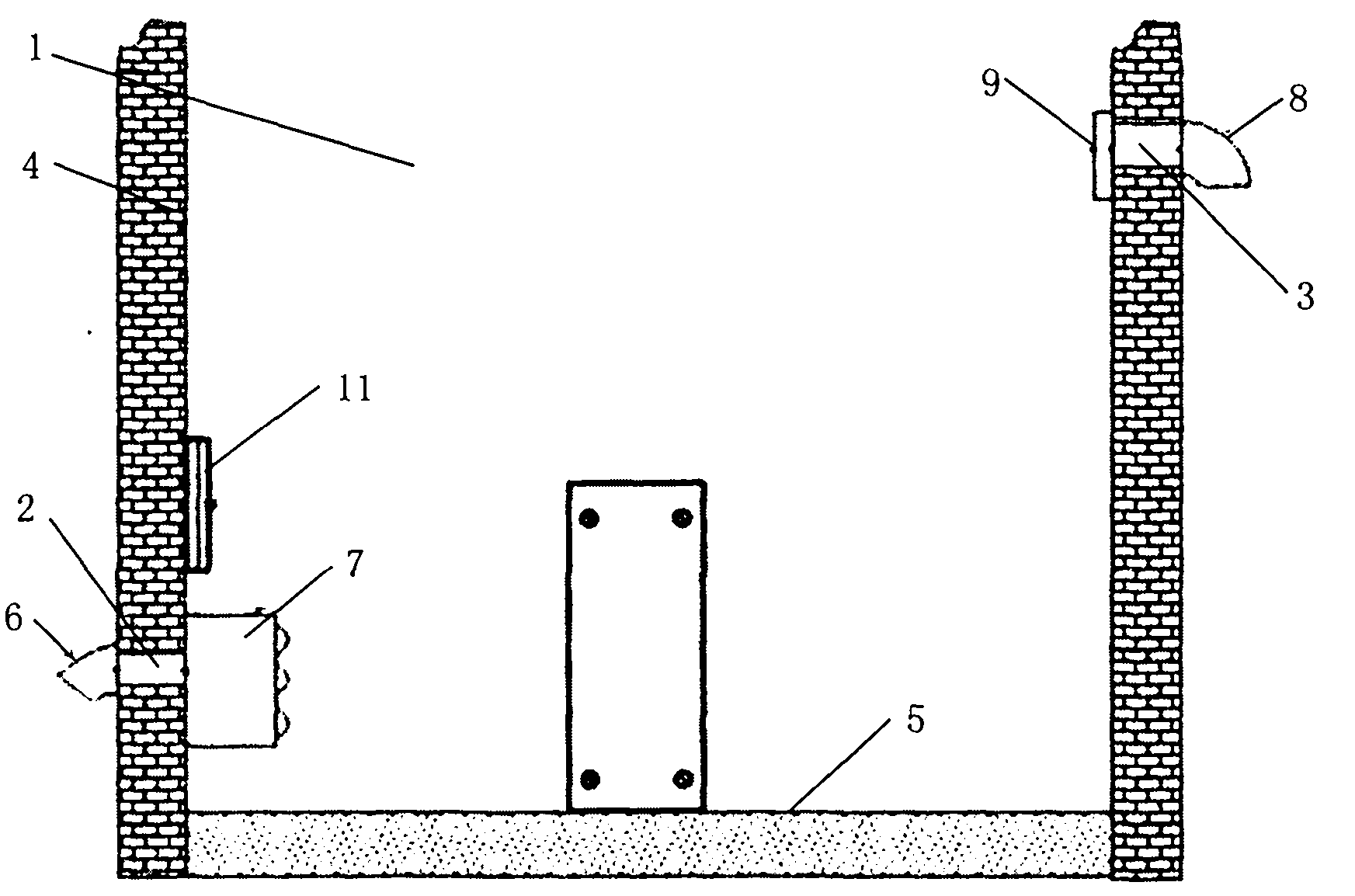

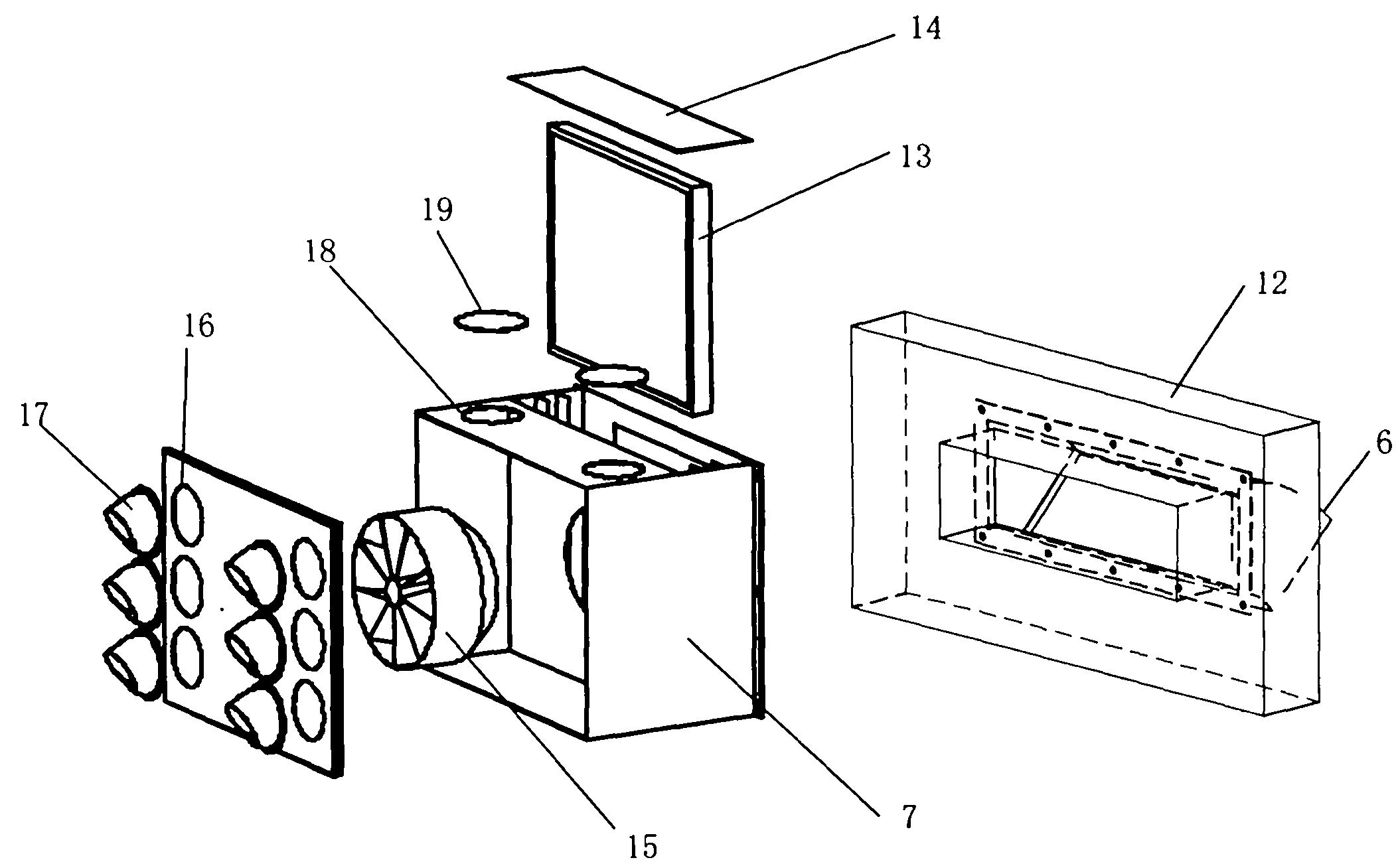

Fresh air energy-saving system for small communication machine room

InactiveCN102829517ALess investmentEasy to useSpace heating and ventilation safety systemsLighting and heating apparatusFresh airMonitoring system

The invention discloses a fresh air energy-saving system for a small communication machine room. A fresh air handling unit, an air exhaust unit and an air-conditioner are separately arranged; an accurate monitoring system is added; the fresh air handling unit adopts a G4-level coarse filter and a backward curved-blade type centrifugal fresh air unit; a special air pressure valve and a rotatable efflux nozzle are added; the air exhaust unit adopts an axial-flow type exhaust fan; the monitoring system is provided with a system control board connected with a remote monitoring computer; and the monitoring system can control automatically through a monitor. Therefore, the temperature of the communication machine room is effectively stabilized; the device investment is reduced; the device fault rate is decreased; the service life of the device is prolonged; and the fresh air energy-saving system can be used safely in an energy-saving manner for a long period of time.

Owner:SHANGHAI JUSHE MACHINERY MFG

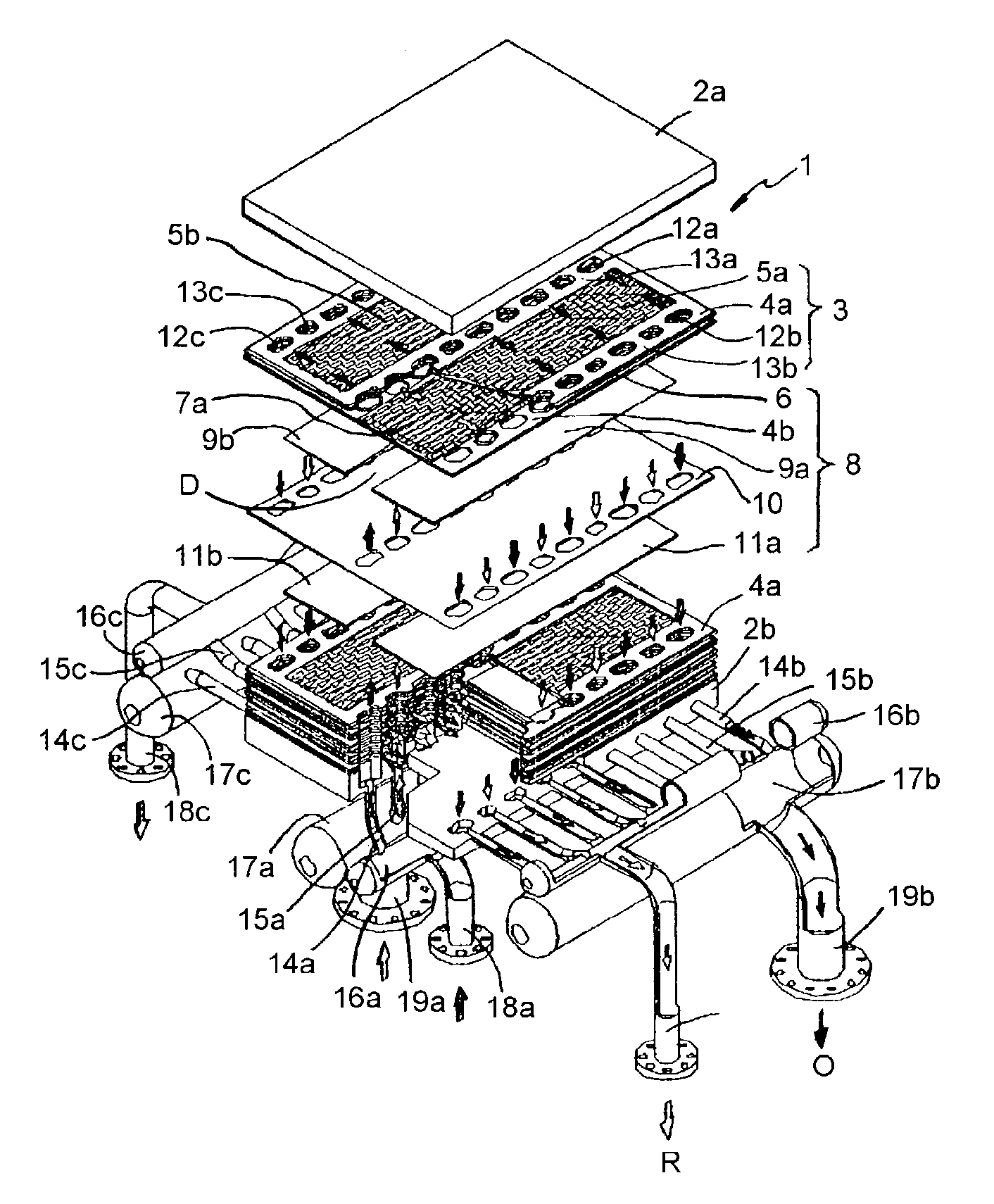

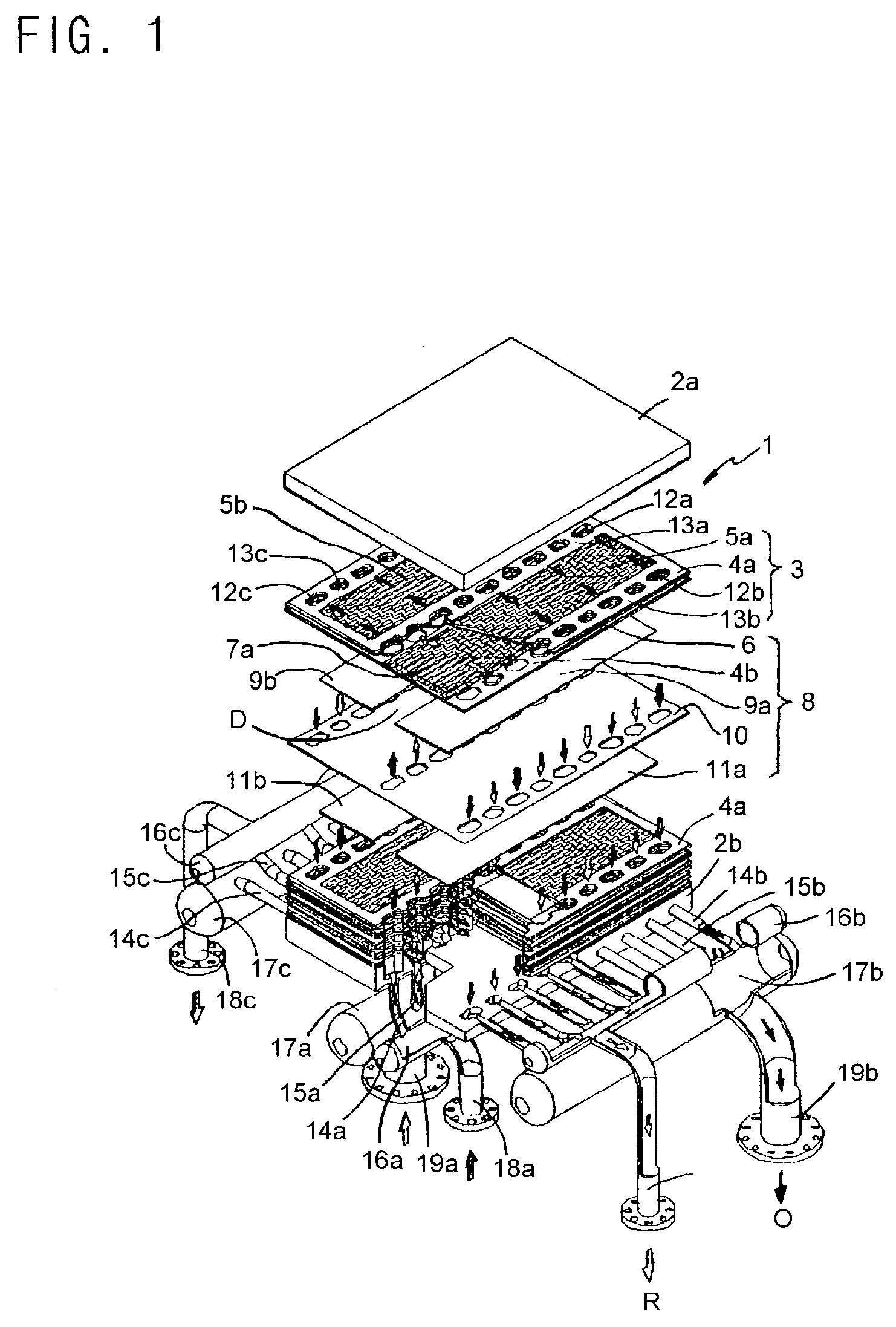

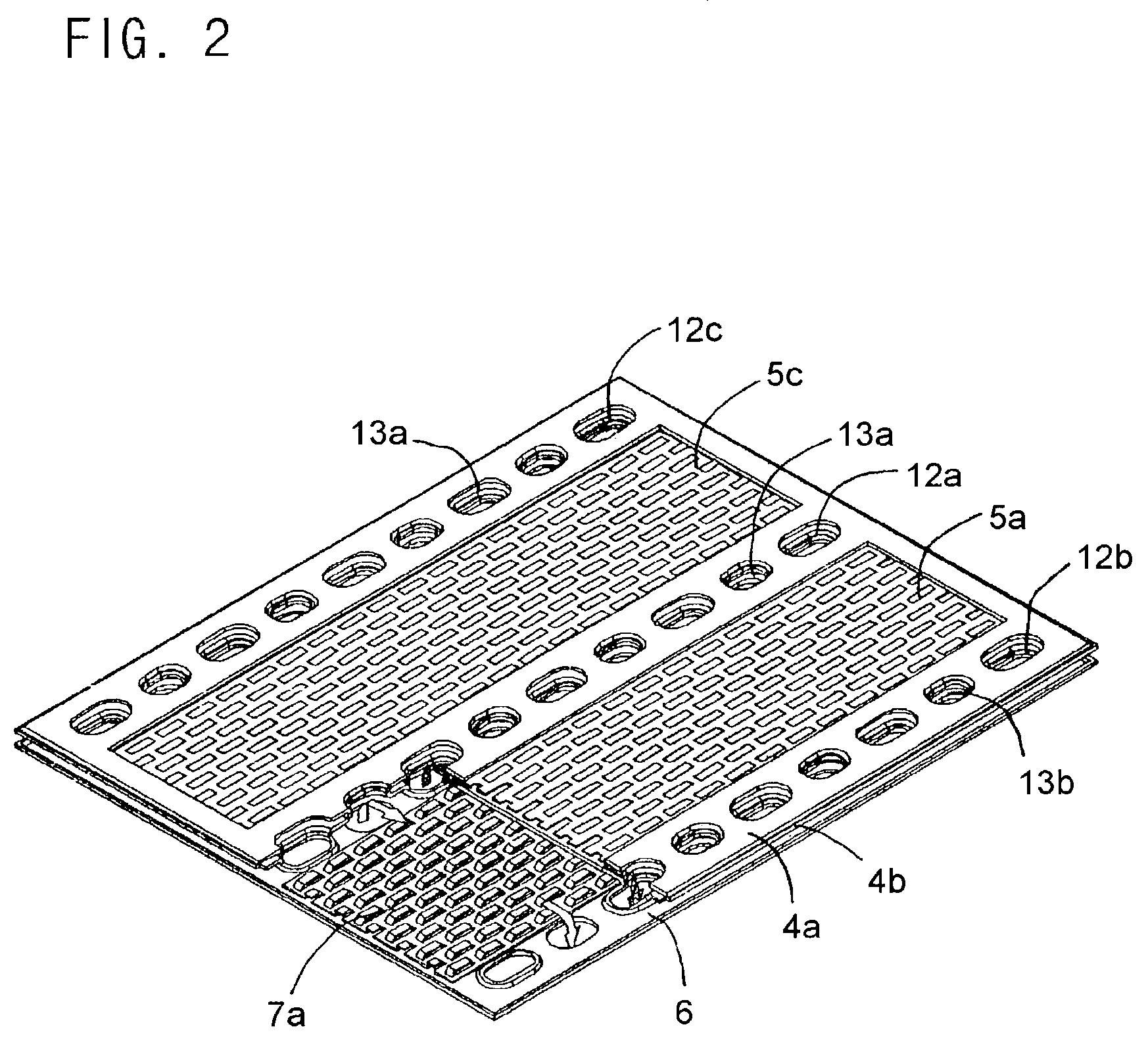

Molten carbonate fuel cell

ActiveUS7097929B2Prevent fuel leakageImprove reliabilityFuel cells groupingFuel cell auxillariesFuel cellsMolten carbonate fuel cell

Disclosed is a molten carbonate fuel cell capable of preventing the leakage of a fuel gas due to deterioration of material by suppressing a high temperature generated at a hot section within a unit cell, thereby improving the reliability thereof. The present invention provides a molten carbonate fuel cell including a plurality of stacked unit cells 8, and separator plates 3 interposed between the adjacent unit cells, the respective unit cells having porous fuel electrode plates 9a and 9b, air electrode plates 11a and 11b, and electrolyte plates 10 interposed between these electrode plates; wherein the separator plate 3 forming a body 1 of the unit cell 8 is provided with at a center thereof intake internal manifolds 12a and 13a arranged at regular intervals for taking in fuel gas R and oxidant gas O towards a center of the body, and at both sides thereof exhaust internal manifolds 12b, 12c, 13b and 13c for exhausting the reacted fuel gas R and the reacted oxidant gas O, as well as forming passages for the fuel gas R ad the oxidant gas O at both sides thereof.

Owner:KOREA ELECTRIC POWER CORP

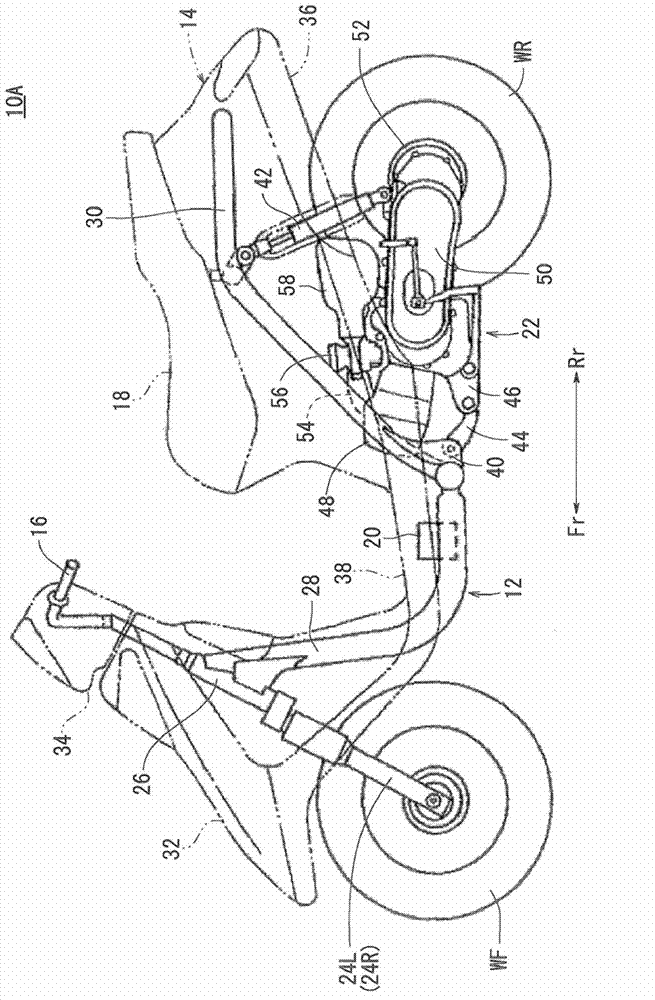

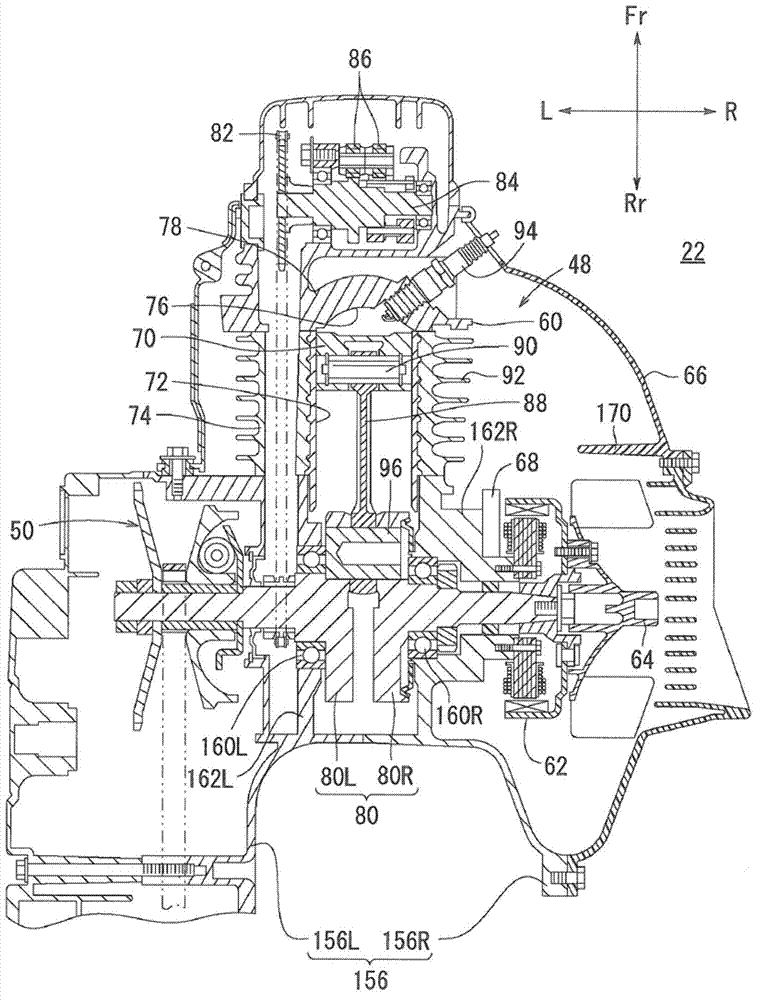

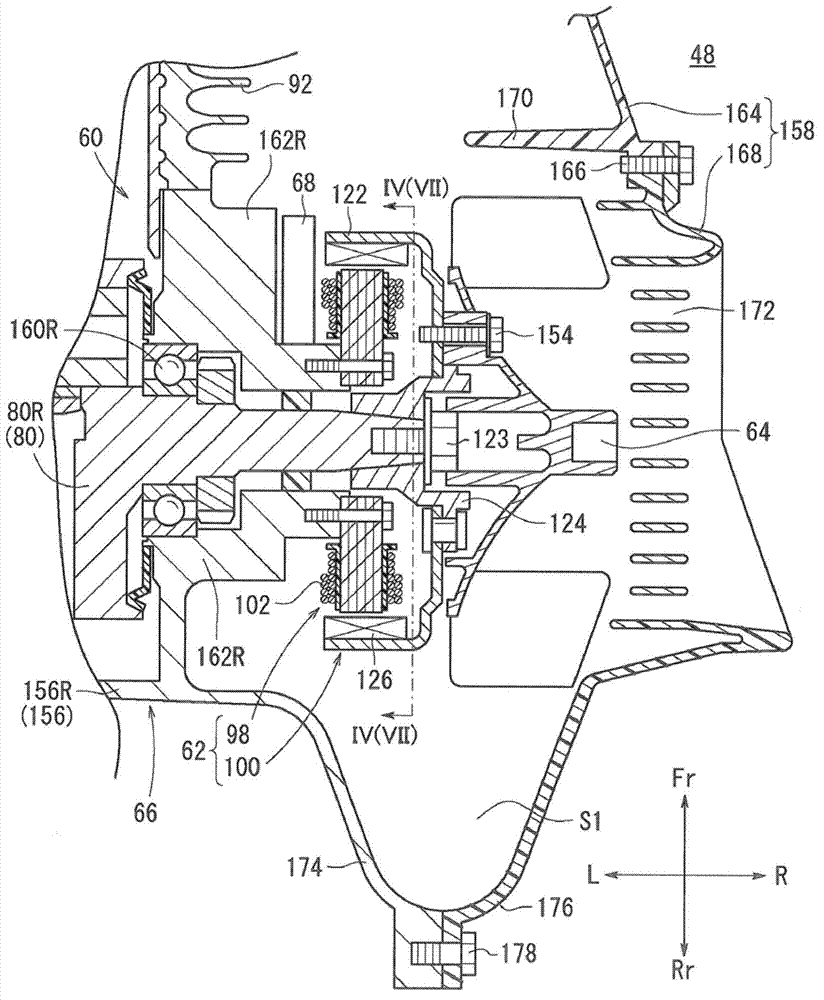

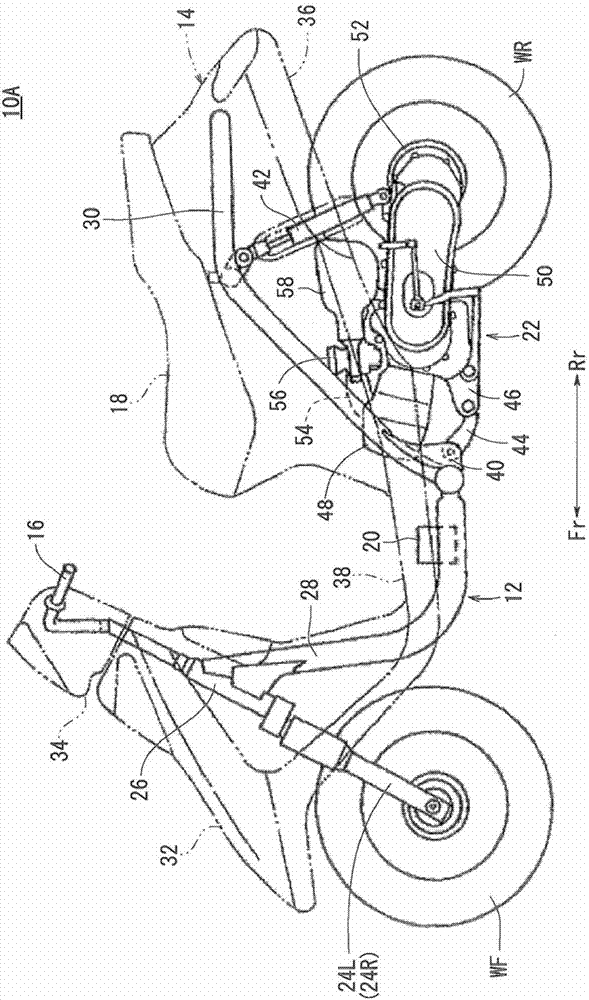

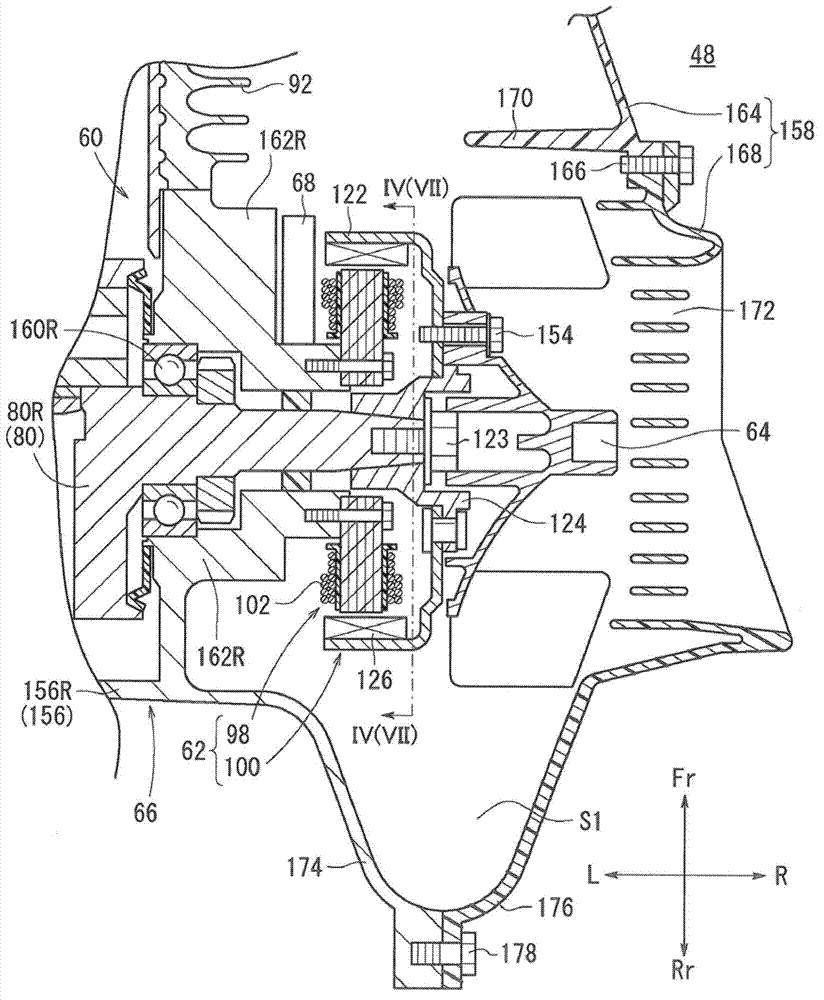

Vehicle

ActiveCN103032244AShorten the lengthSave configuration spaceCycle equipmentsElectric motor startersElectricityVehicle frame

The invention provides a vehicle which controls accommodation space of wires into a minimum limit by shortening the length between a plurality of coils forming a rotary motor stator and a control unit, and allows the control unit to be compactly mounted on an engine. A two-wheeled motor vehicle (10A) is provided with a swinging unit (22) which is disposed on a vehicle frame (12) and comprises an engine (48). The engine (48) comprises a rotary motor (62) which comprises a stator (98) and an outer rotor (100) comprising a plurality of coils (110); a storage battery (20) electrically connected with the plurality of coils (110); a crankshaft (80) rotatably connected with the outer rotor (100) for rotation; and a control unit (68) which controls power current by switching on and off the connection of the plurality of coils (110) with the storage battery (20), and thus allows the rotary motor (62) to act as a motor or a generator. The control unit (68) is disposed near the rotary motor (62).

Owner:HONDA MOTOR CO LTD

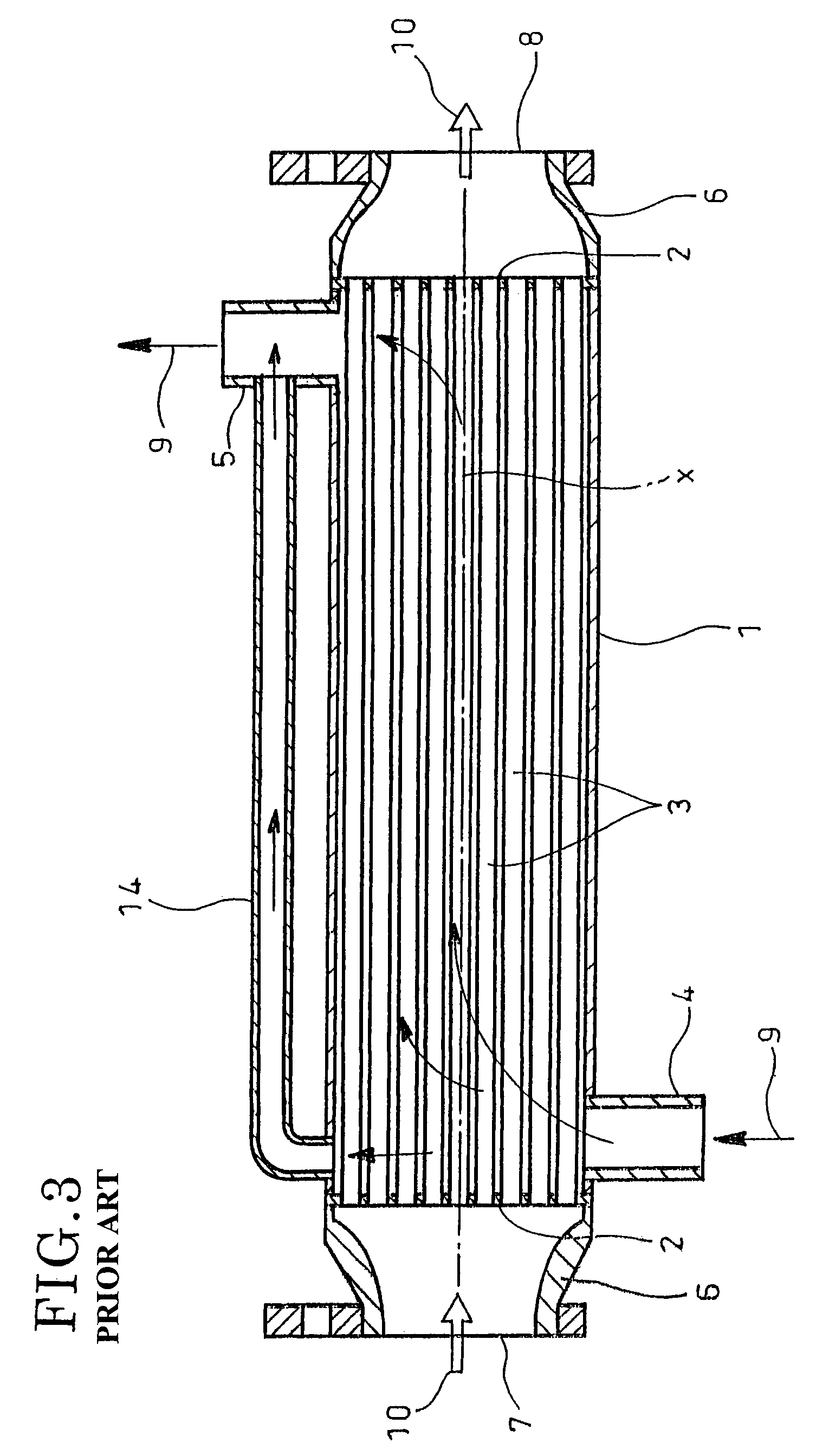

EGR cooler

InactiveUS7594536B2Suppress high temperatureImprove installabilityAir-treating devicesNon-fuel substance addition to fuelDiesel engineChiller

An EGR cooler including tubes and a shell enclosing the tubes. Cooling water is supplied into and discharged from the shell. Exhaust gas is guided from a diesel engine into the tubes for thermal exchange of the exhaust gas with the cooling water. A bypass flow path for guiding the cooling water is constituted within the shell so as to prevent stagnation of the cooling water in the shell.

Owner:HINO MOTORS LTD +2

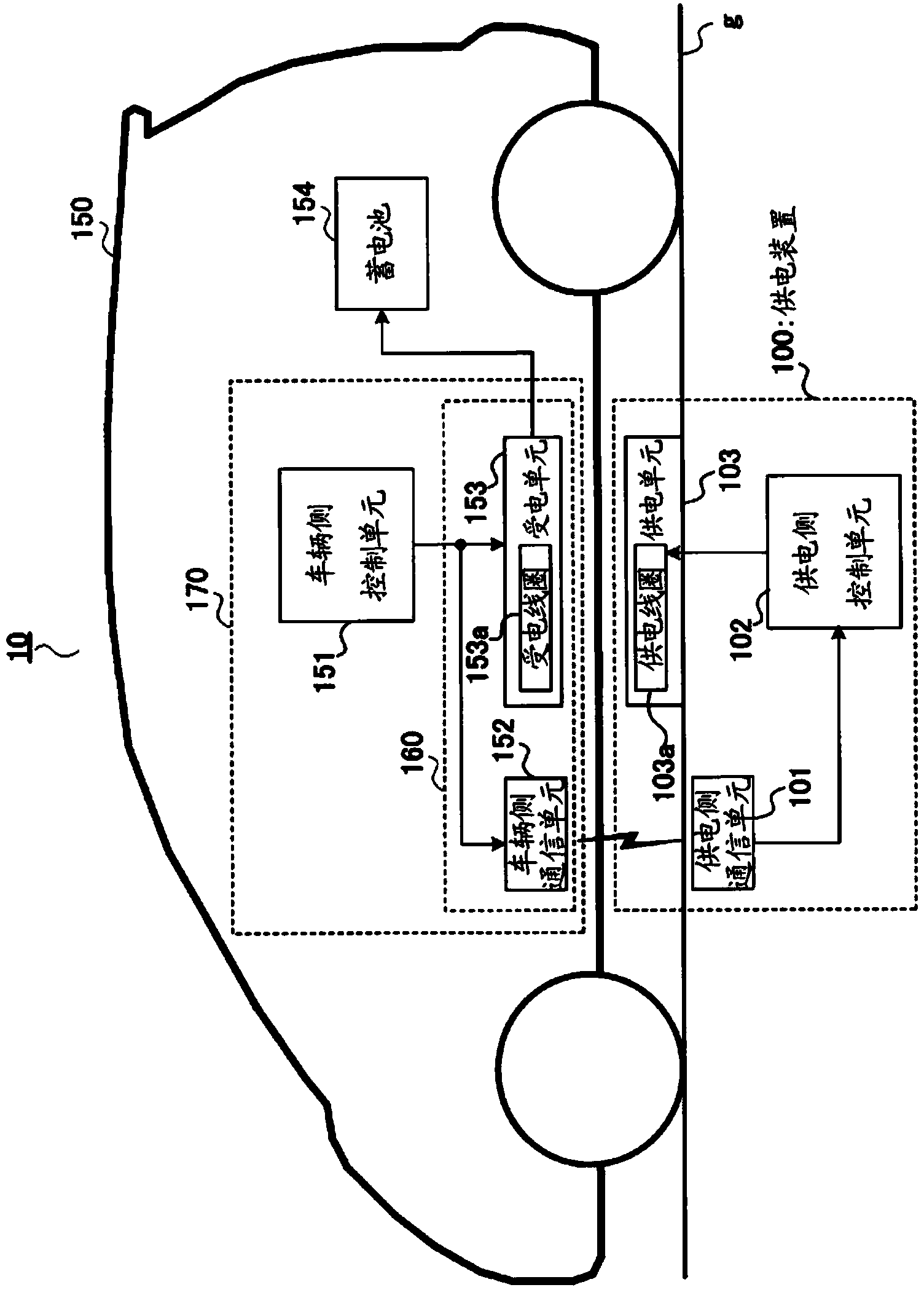

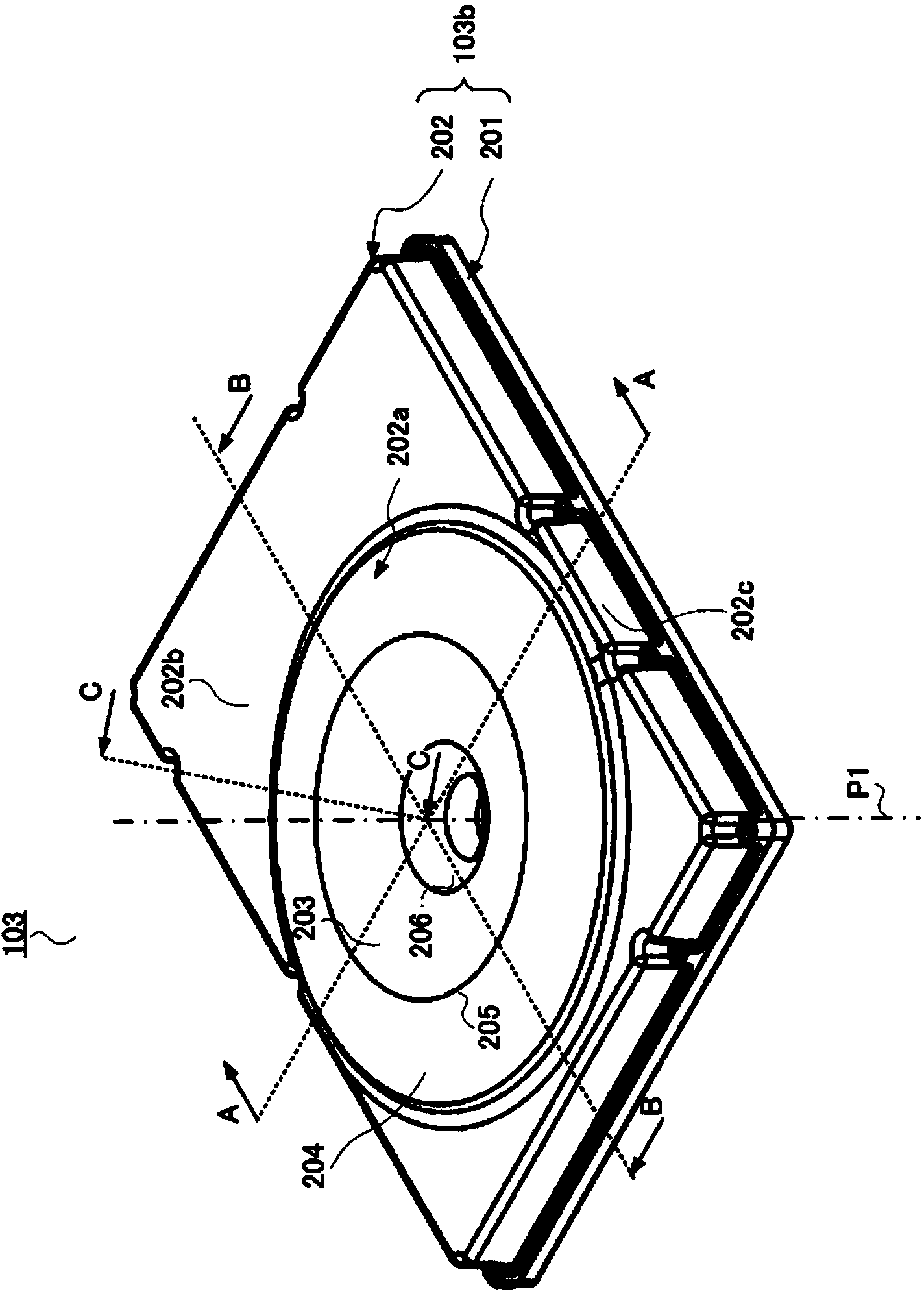

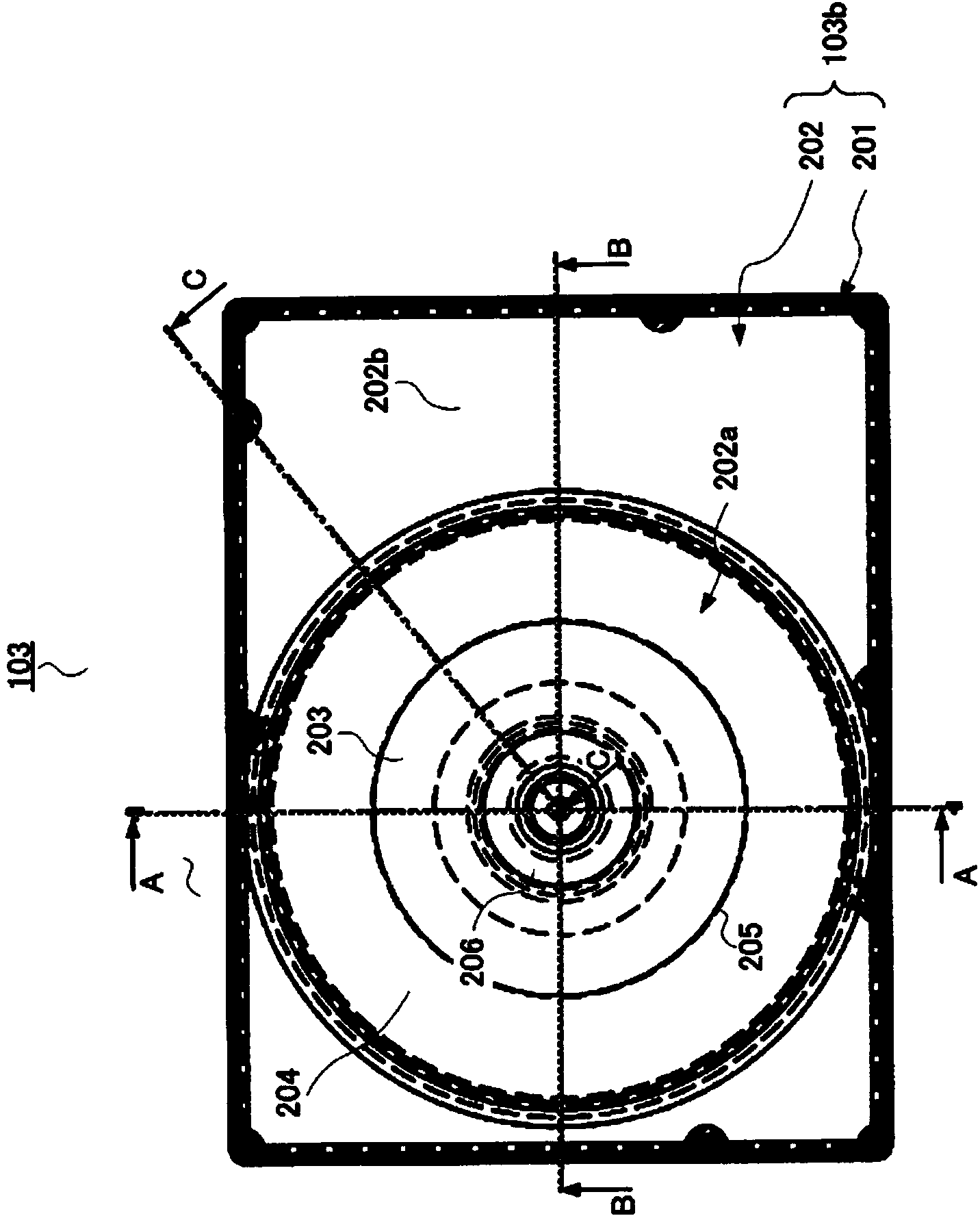

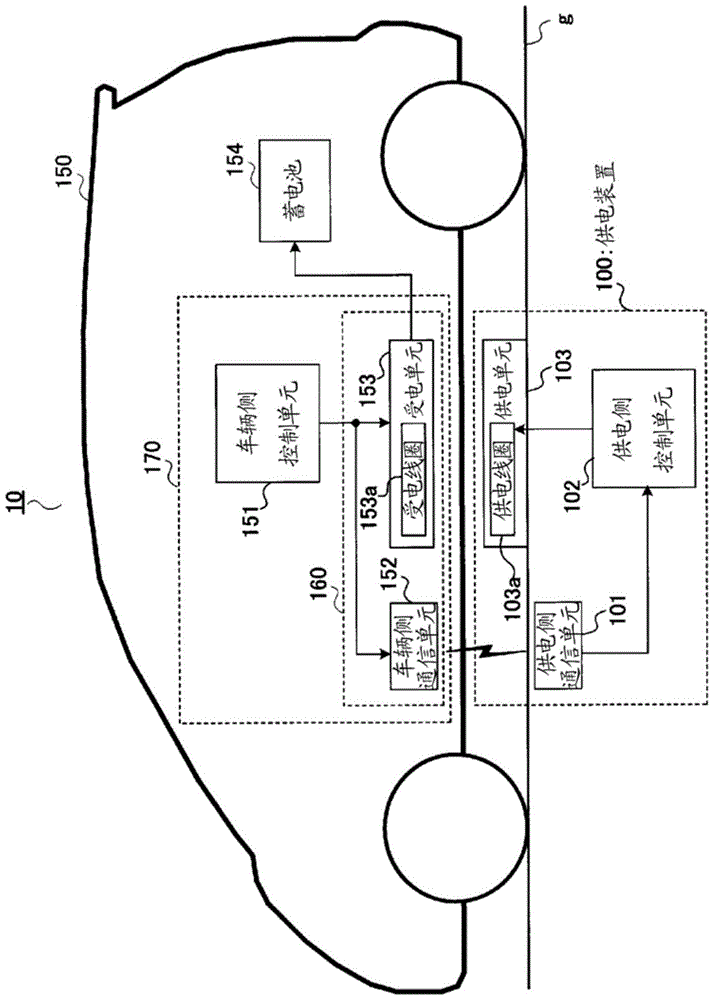

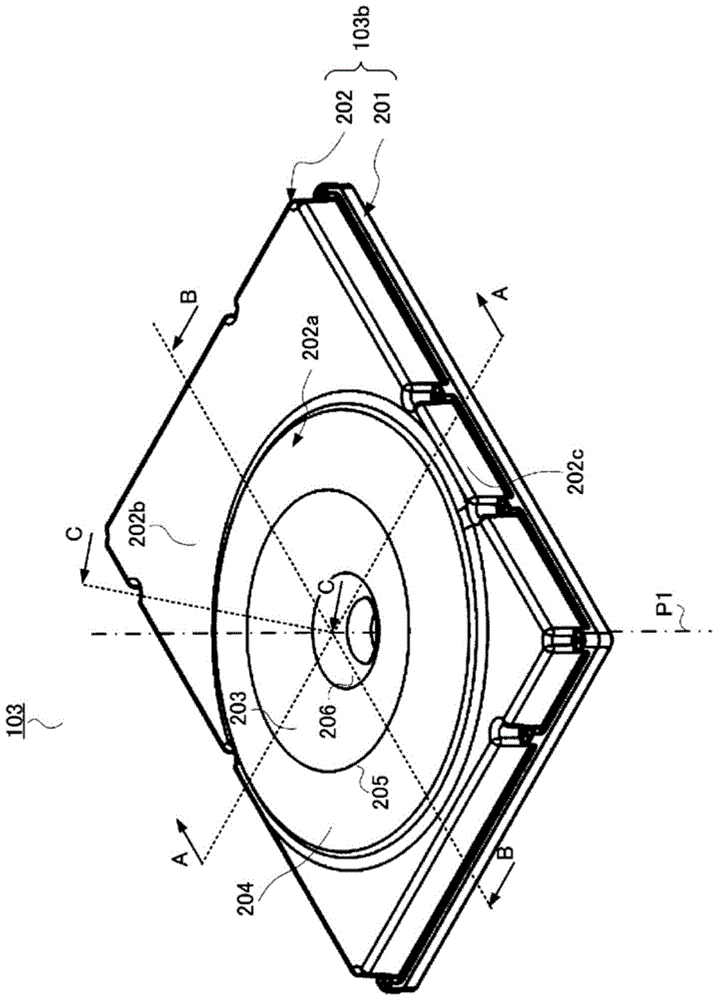

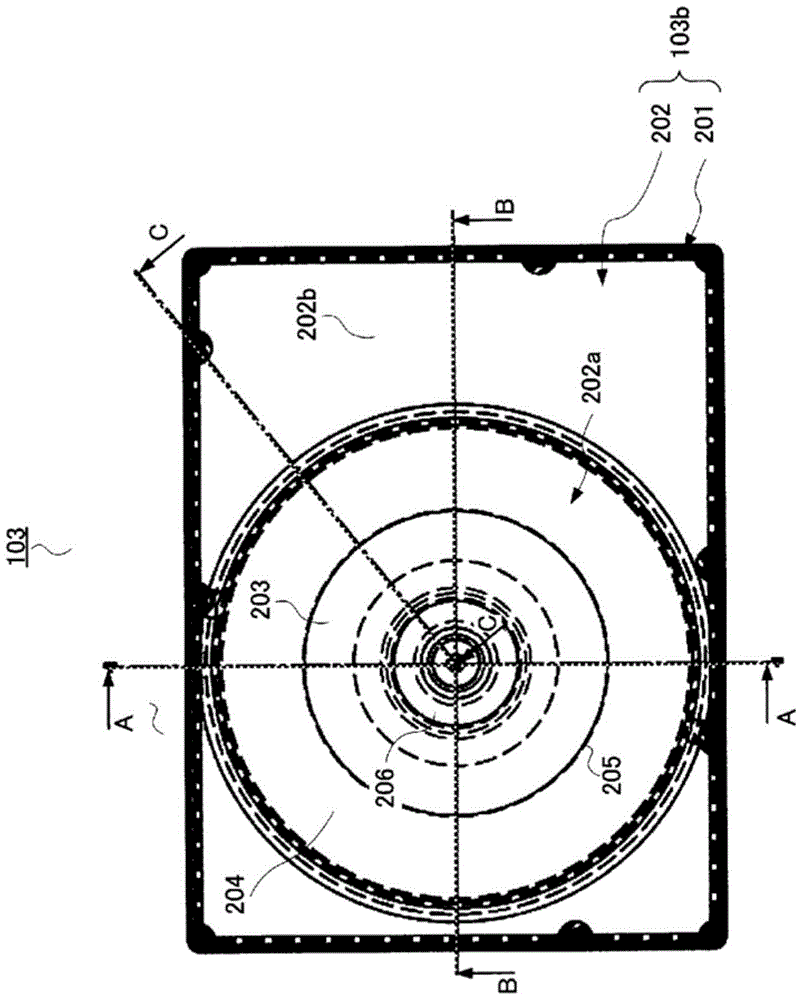

Power supply apparatus

ActiveCN104170210ASuppress high temperatureCharging stationsElectromagnetic wave systemElectricityForeign substance

A power supply apparatus capable of inhibiting temperature increase of a foreign substance heated during power supply while suppressing the thickness of a cabinet surface. In the power supply apparatus (100), on a top surface (202a), which is the surface opposing the power-receiving unit (153) of a cabinet (103b), in the portion where a power supply coil (103a) is projected when the power supply coil (103a) is projected on the cabinet (103b) toward the direction of the power-receiving unit (153), a first inclined part (203) gradually approaching the power supply coil (103a) from the top section (205) toward the inner edge section (211) of the power supply coil (103a) is formed in the radial direction of the power supply coil (103a), and in the portion where the power supply coil (103a) is projected, a second inclined part (204) gradually approaching the power supply coil (103a); from the top section (205) toward the outer periphery (212) of the power supply coil (103a) is formed in the radial direction of the power supply coil (103a).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

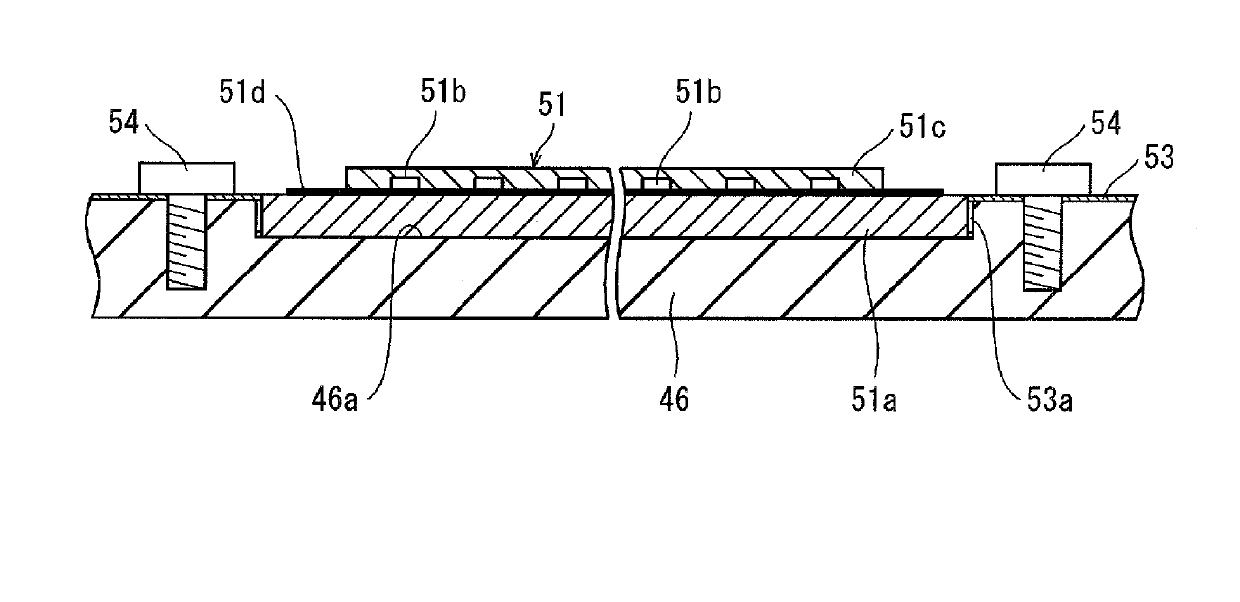

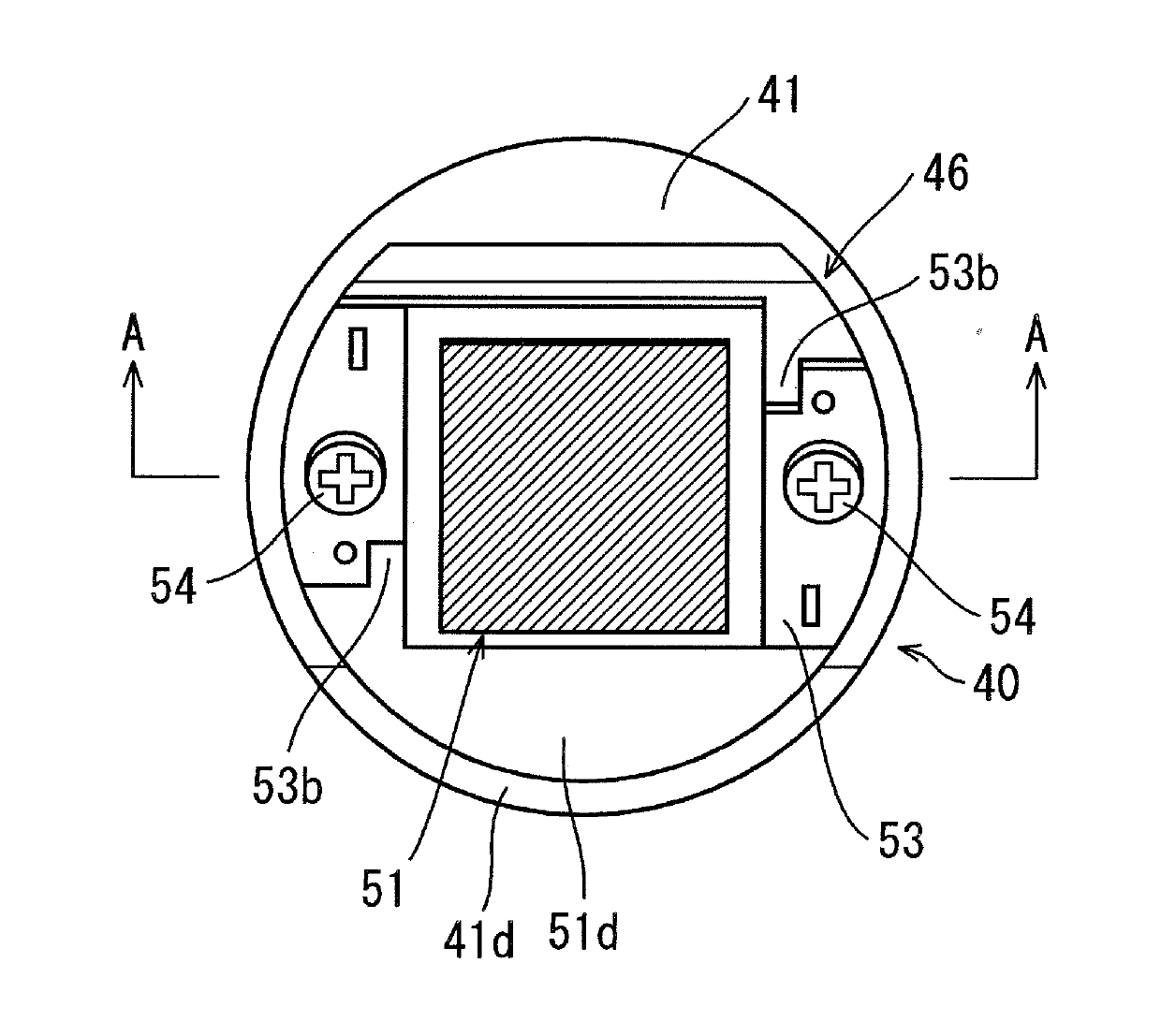

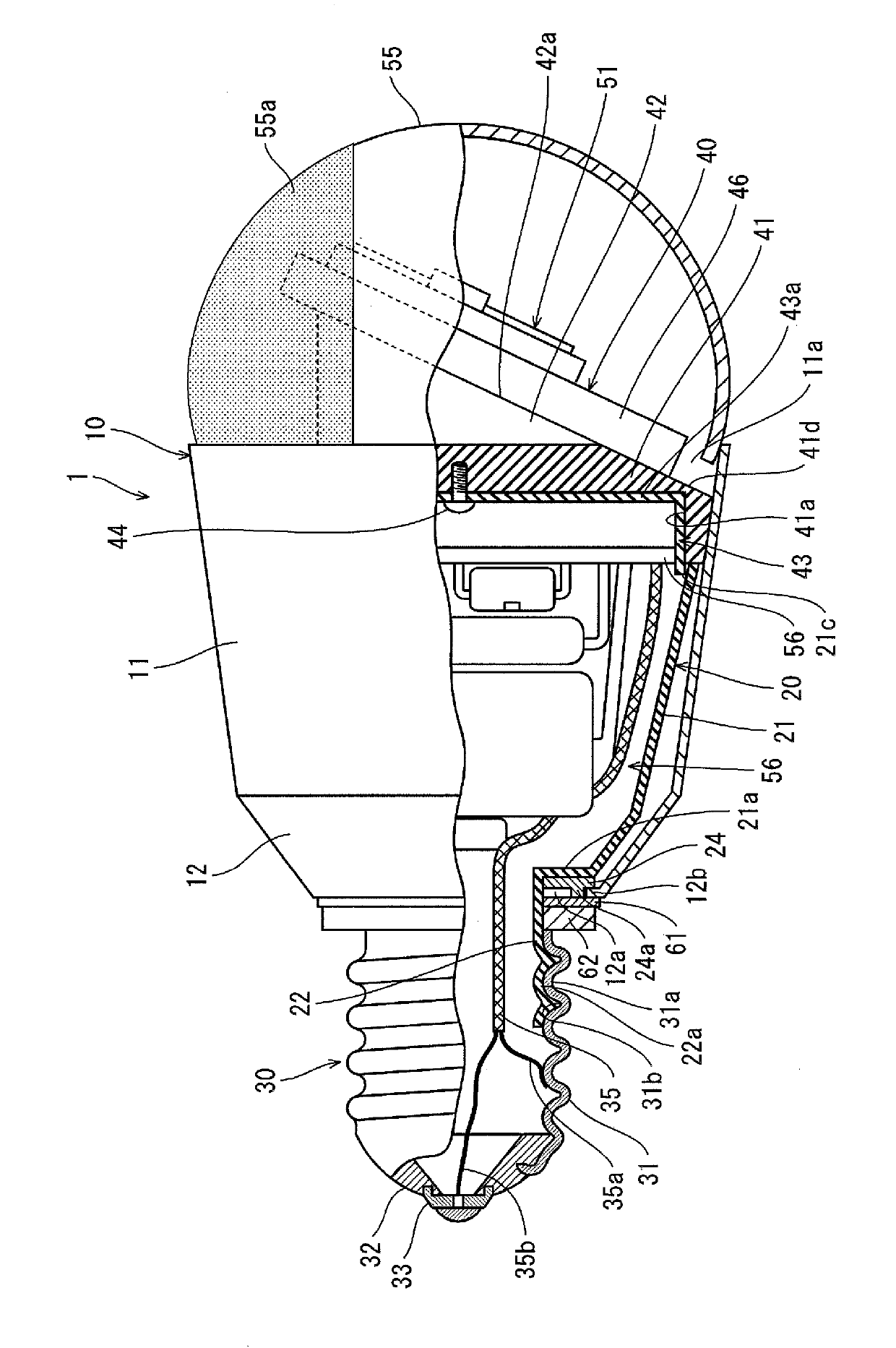

Bulb-shaped lamp

ActiveCN102472458AEasy to adjustIncrease the areaPoint-like light sourceElectric circuit arrangementsEngineeringLight head

Disclosed is a bulb-shaped lamp wherein one end of a tube-shaped seat (10) is rotatably attached around an end of a cylindrical base (30) fitted into a socket of a lighting fixture. A support mount (40) is attached to the other end of the seat (10) so as to be able to rotate as a single unit with said seat (10). An LED module (51) that has a plurality of LED chips is attached to the support mount (40). The support mount (40) is provided with an end face (43a) to which the LED module (51) is attached. The end face (43a) is configured such that light emitted from the LED chips provided in the LED module (51) is inclined at a prescribed angle with respect to the axis of the base (30).

Owner:PANASONIC CORP

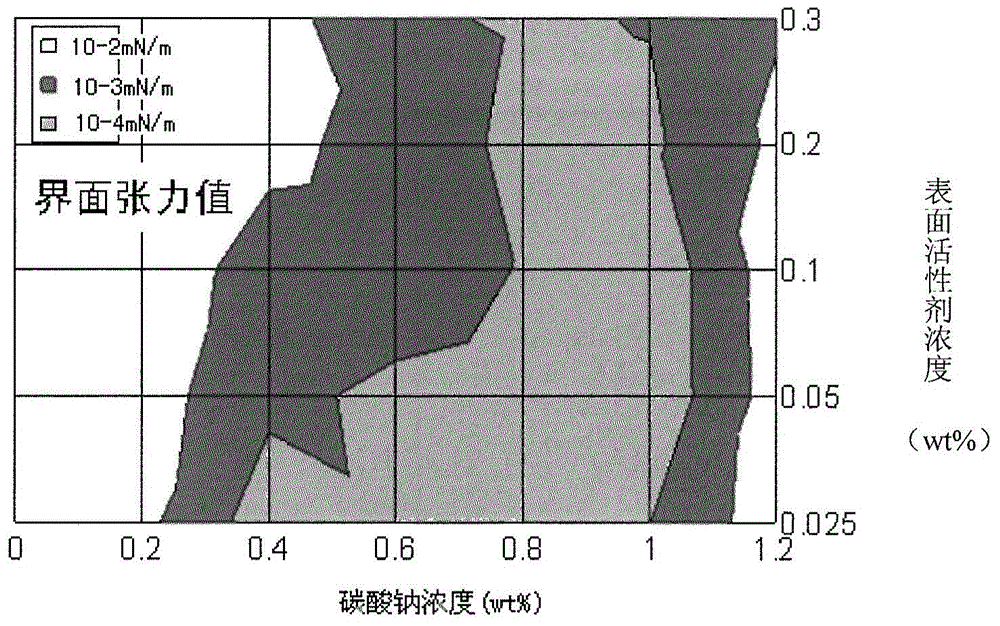

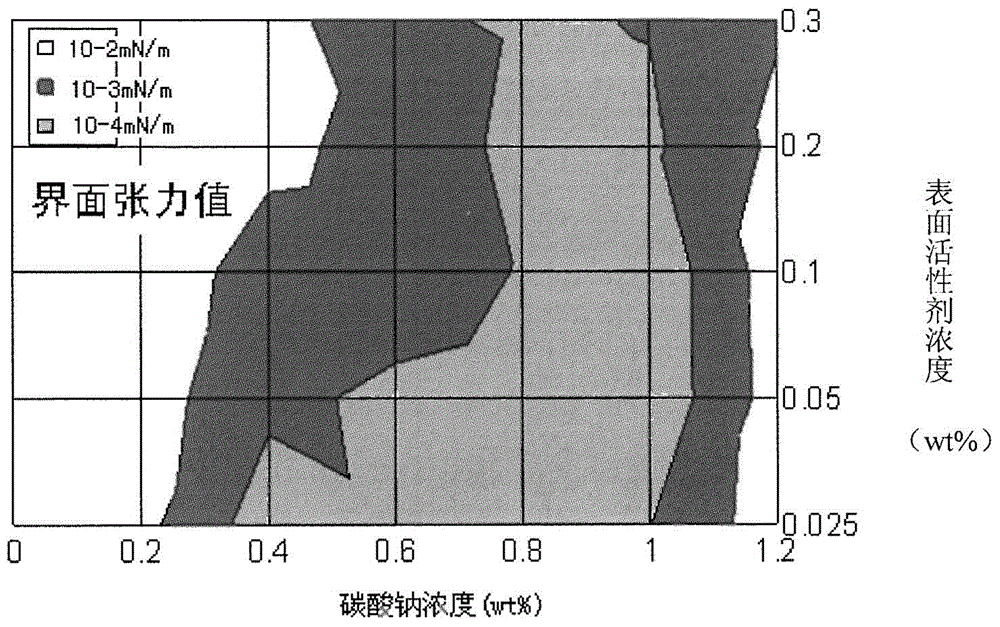

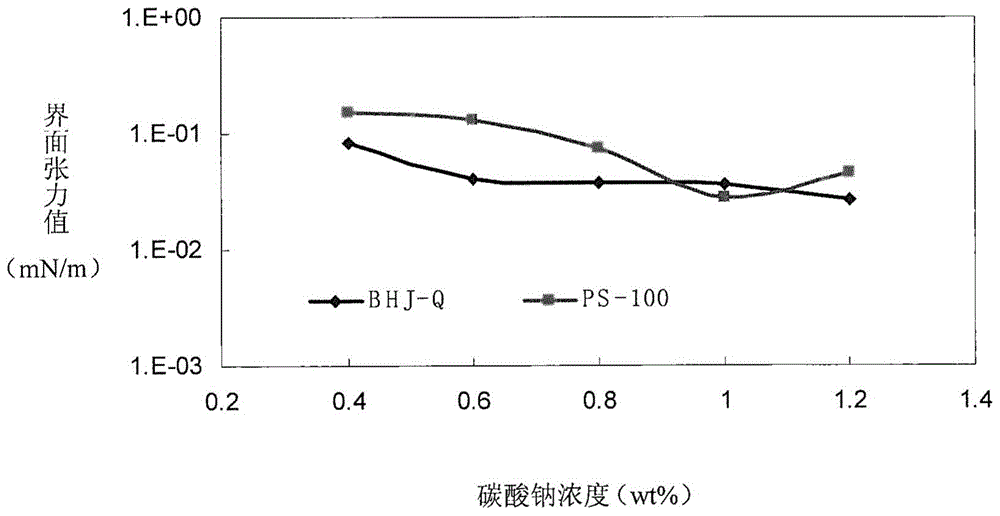

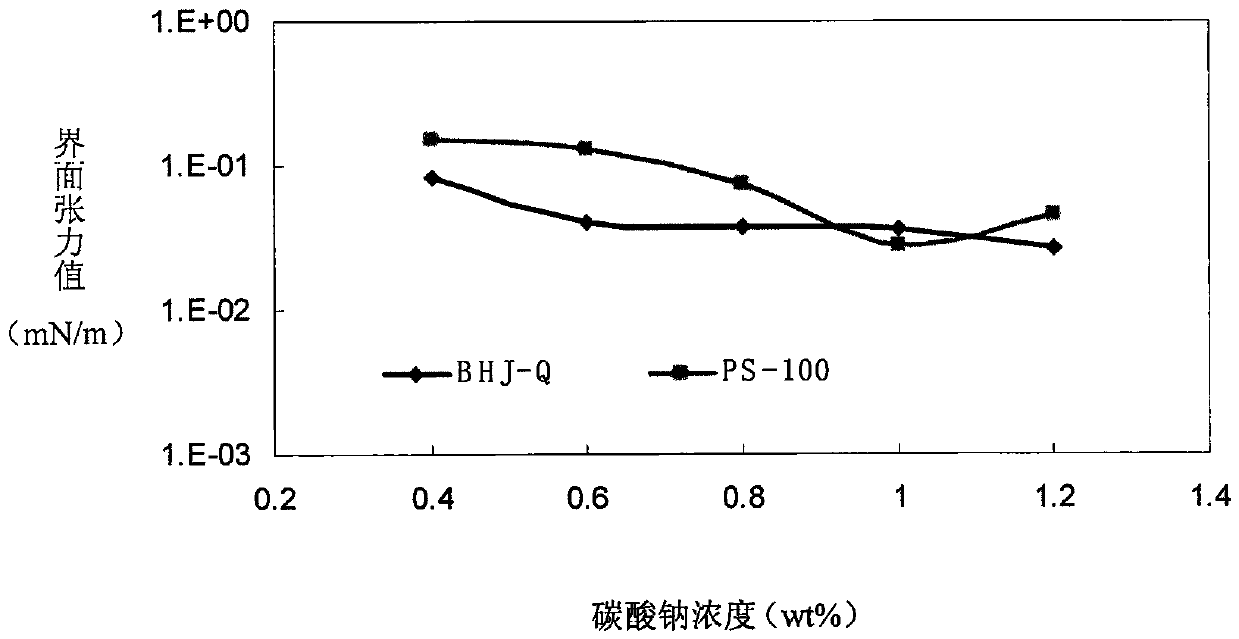

Ternary composite system suitable for high-temperature and high-salinity oil reservoir, and preparation method thereof

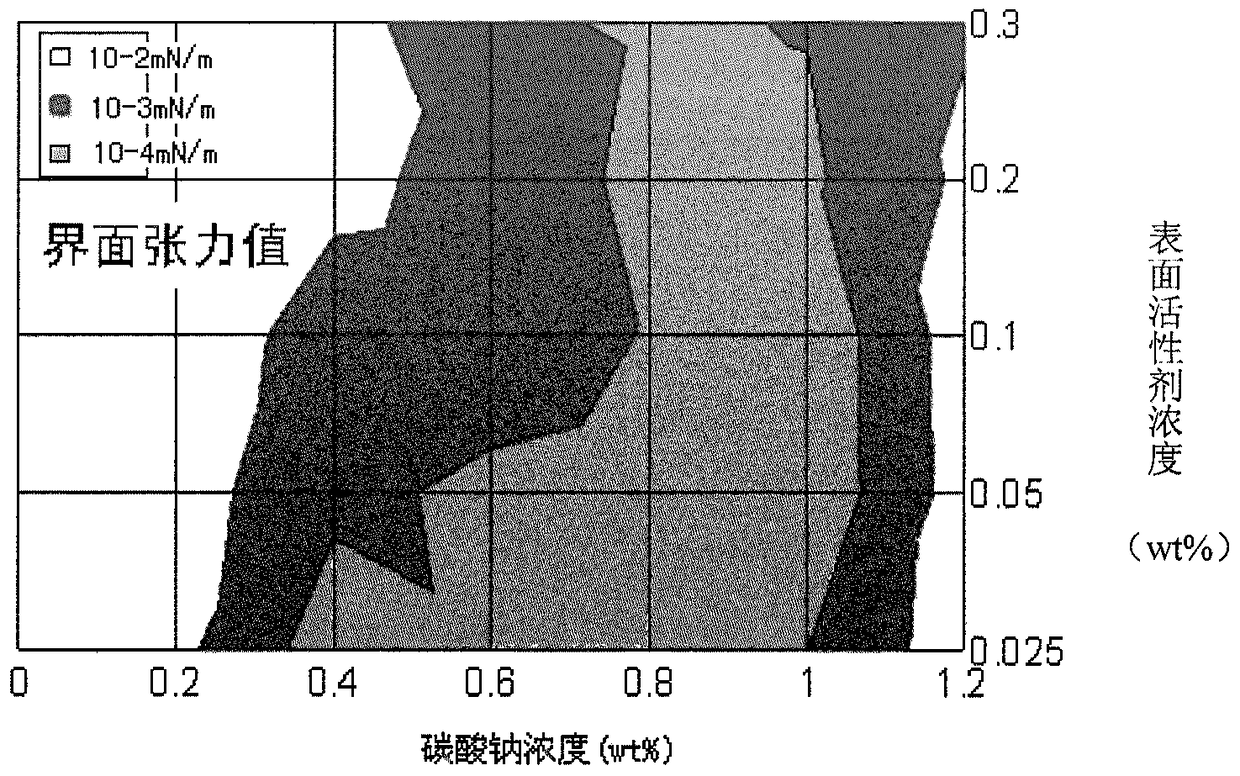

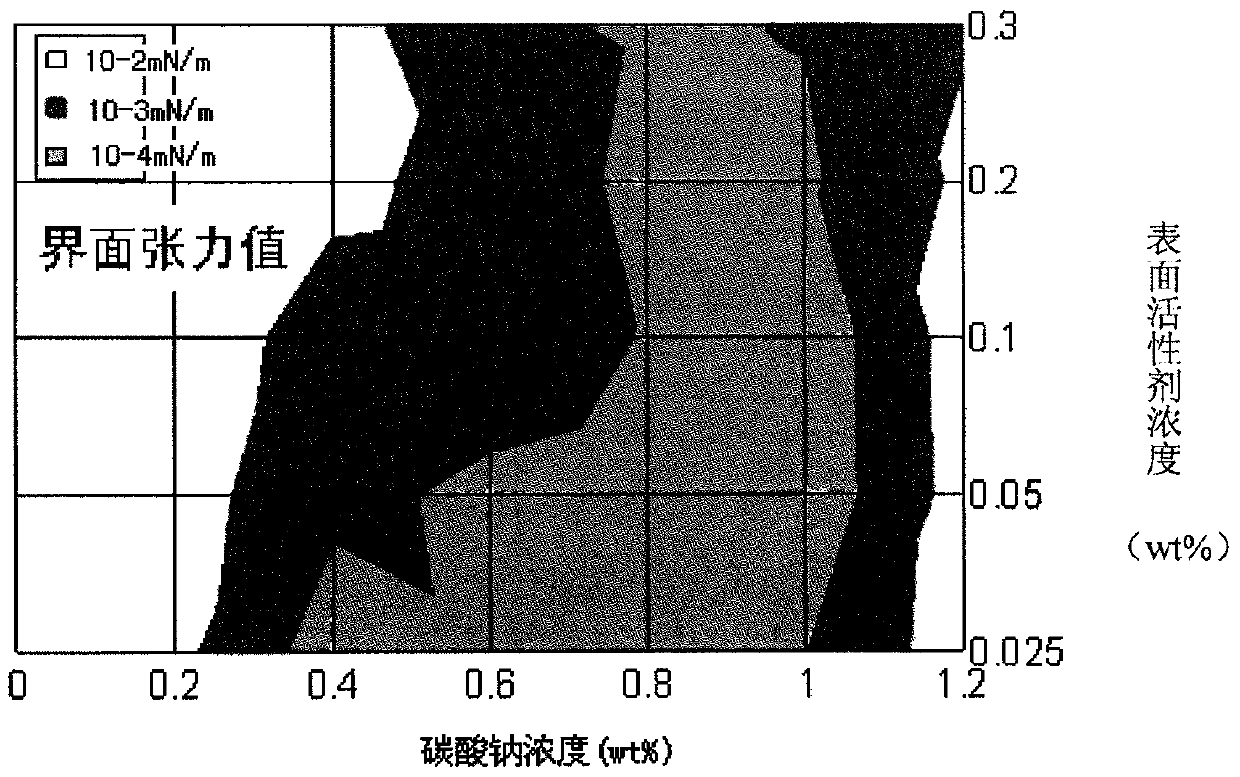

ActiveCN105038754AGood chemical stabilityImprove salt toleranceFluid removalDrilling compositionChemical structureSalt resistance

The present invention discloses a ternary composite system suitable for high-temperature and high-salinity oil reservoir, and a preparation method thereof. The ternary composite system comprises a polymer, a surfactant and sodium carbonate, wherein the chemical structure formula of the polymer is defined in the specification, and the polymer has a network structure and has the effect of effective inhibition of high temperature and oxidation degradation so as to effectively improve salt resistance and strengthen thickening capacity. According to the present invention, after the polymer is introduced into the ternary composite system, the ternary composite system has good chemical stability and excellent salt resistance under the conditions of high temperature and high salinity, makes the crude oil / stratum water interface tension be reduced to an ultra-low level under the weak base sodium carbonate condition, and can improve the recovery rate by more than or equal to 20%, such that the ternary composite system of the present invention can be used for the extreme high-temperature and high-salinity oil reservoir conditions.

Owner:PETROCHINA CO LTD +1

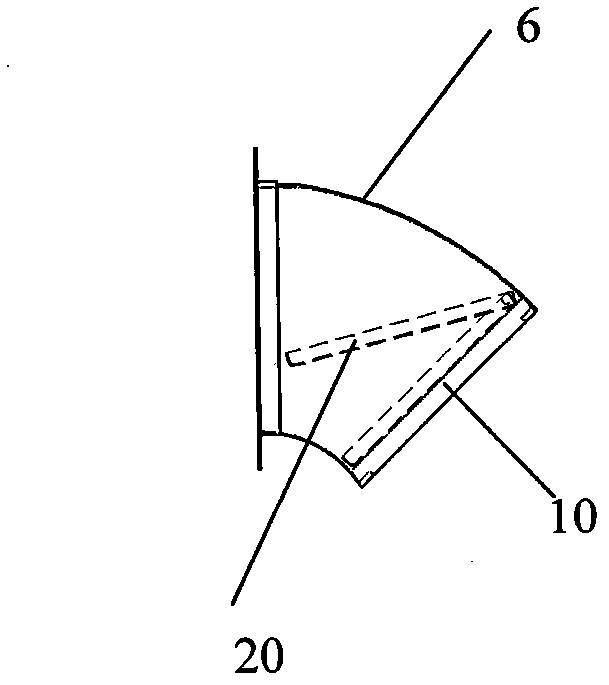

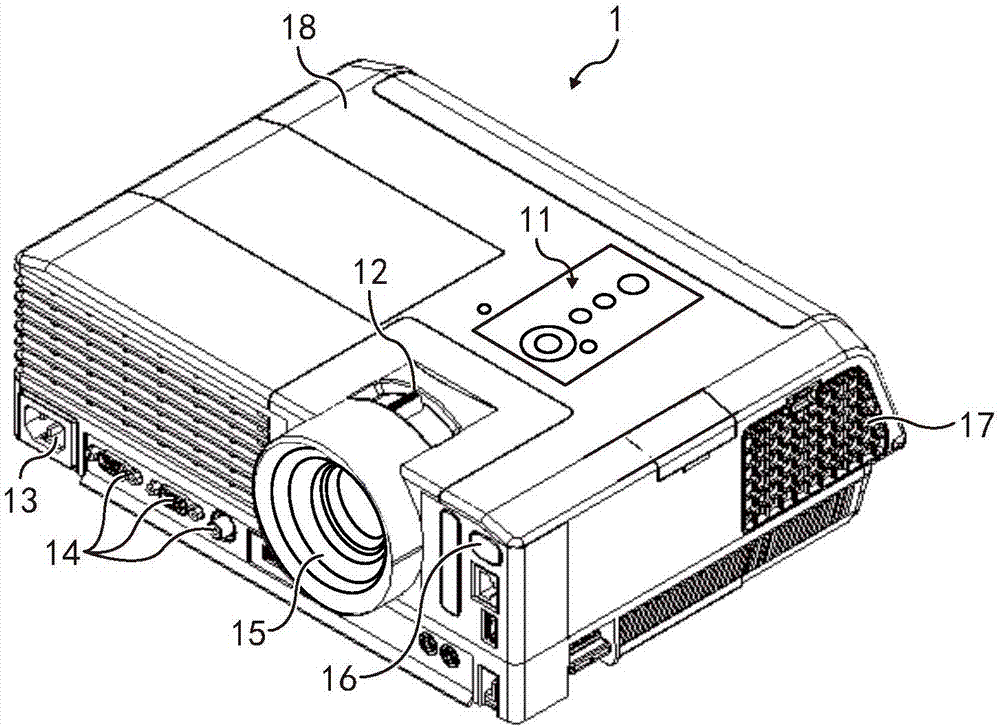

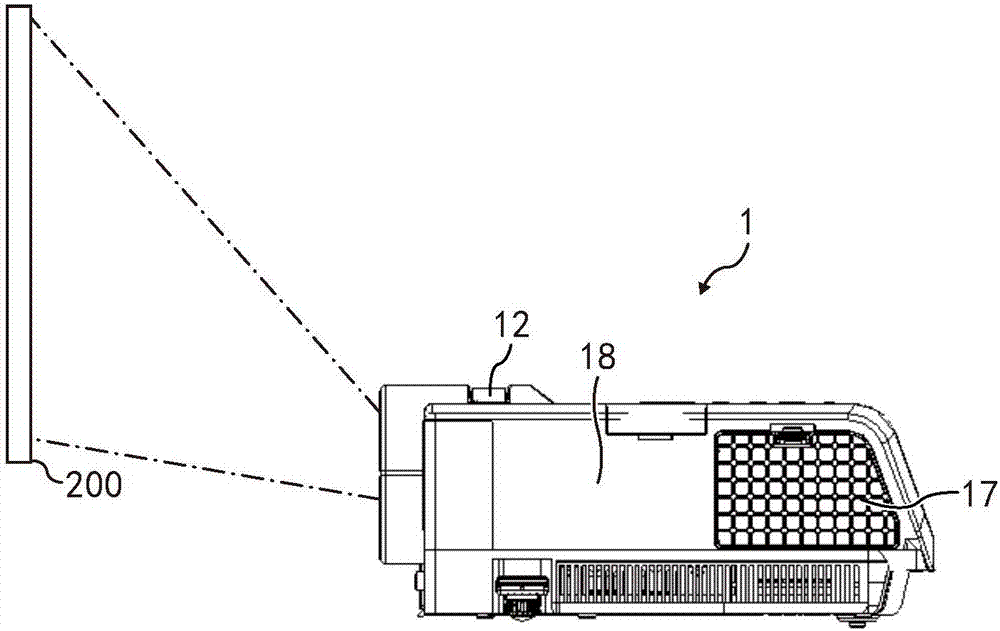

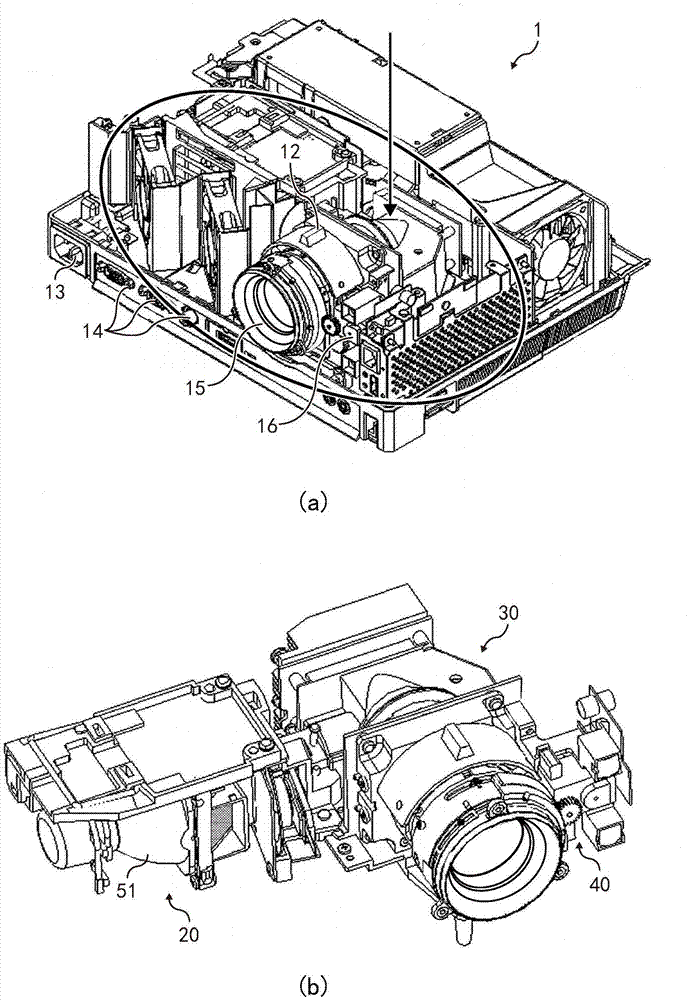

Image projecting device and light source assembly

The invention relates to an image projection device and a light source assembly with a light source and a cover component which are integrally formed. The image projection device and the light source assembly aim to suppress high temperature of the cover component caused by high temperature of the light source in the light source assembly with the light source and the cover component which are integrally formed. The image projection device is provided with the light source assembly (50) which can be detached on the device body through a light source assembly taking-out opening (18a) of the device body. A discharging lamp (51) in the light source assembly is used for transmitting a light projection image. A light source assembly cover (52) of the light source assembly taking-out opening is integrally formed with the light source in a state that relative displacement relative to the light source can be performed. In a mounting state that the light source assembly is mounted on the device body, a direct connecting part or indirect connecting part between the light source and the cover component is restricted to a direct connecting part or indirect connecting part when relative displacement between the light source and the cover component occurs in a non-mounting state in which the light source assembly is not mounted on the device body.

Owner:RICOH KK

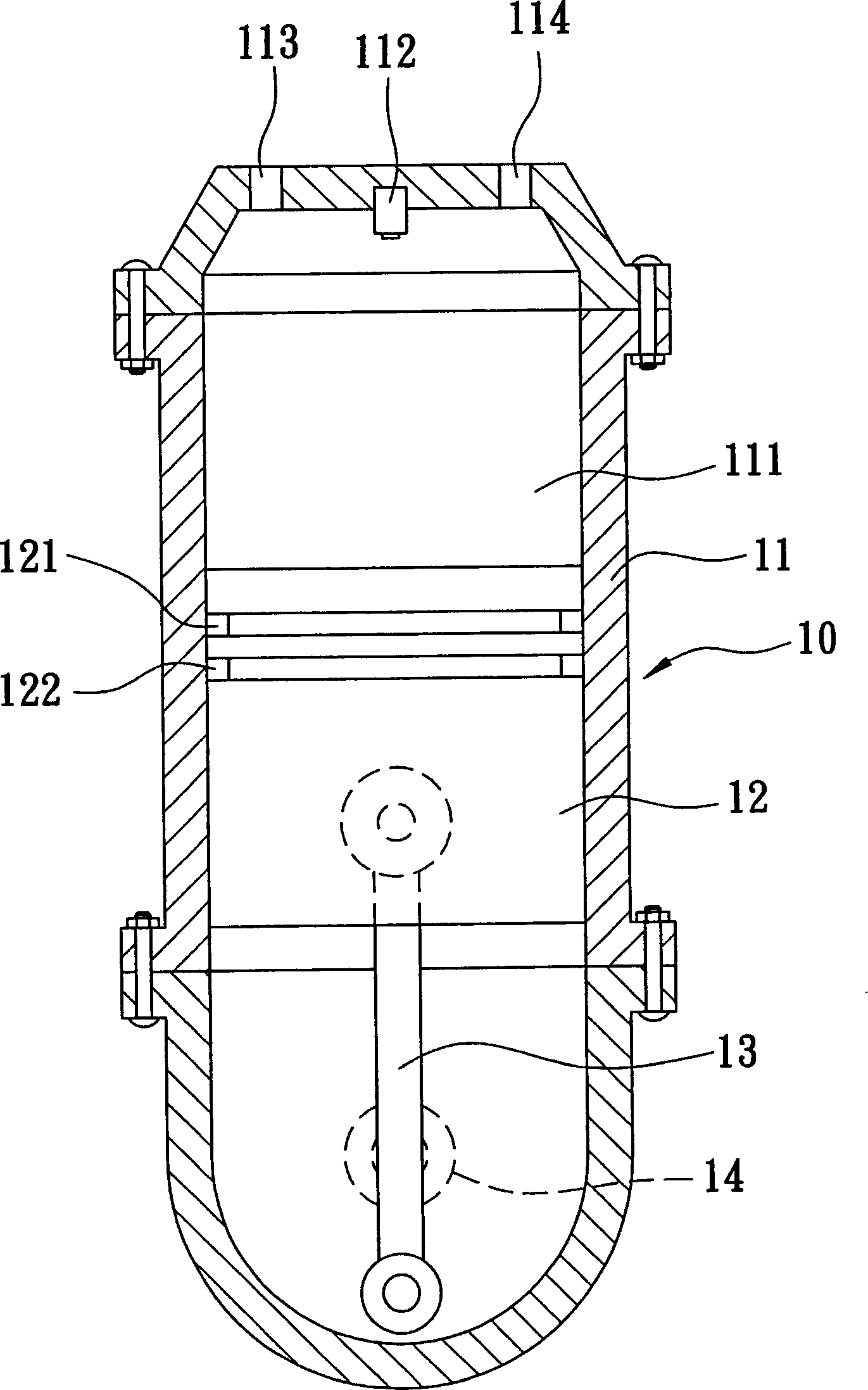

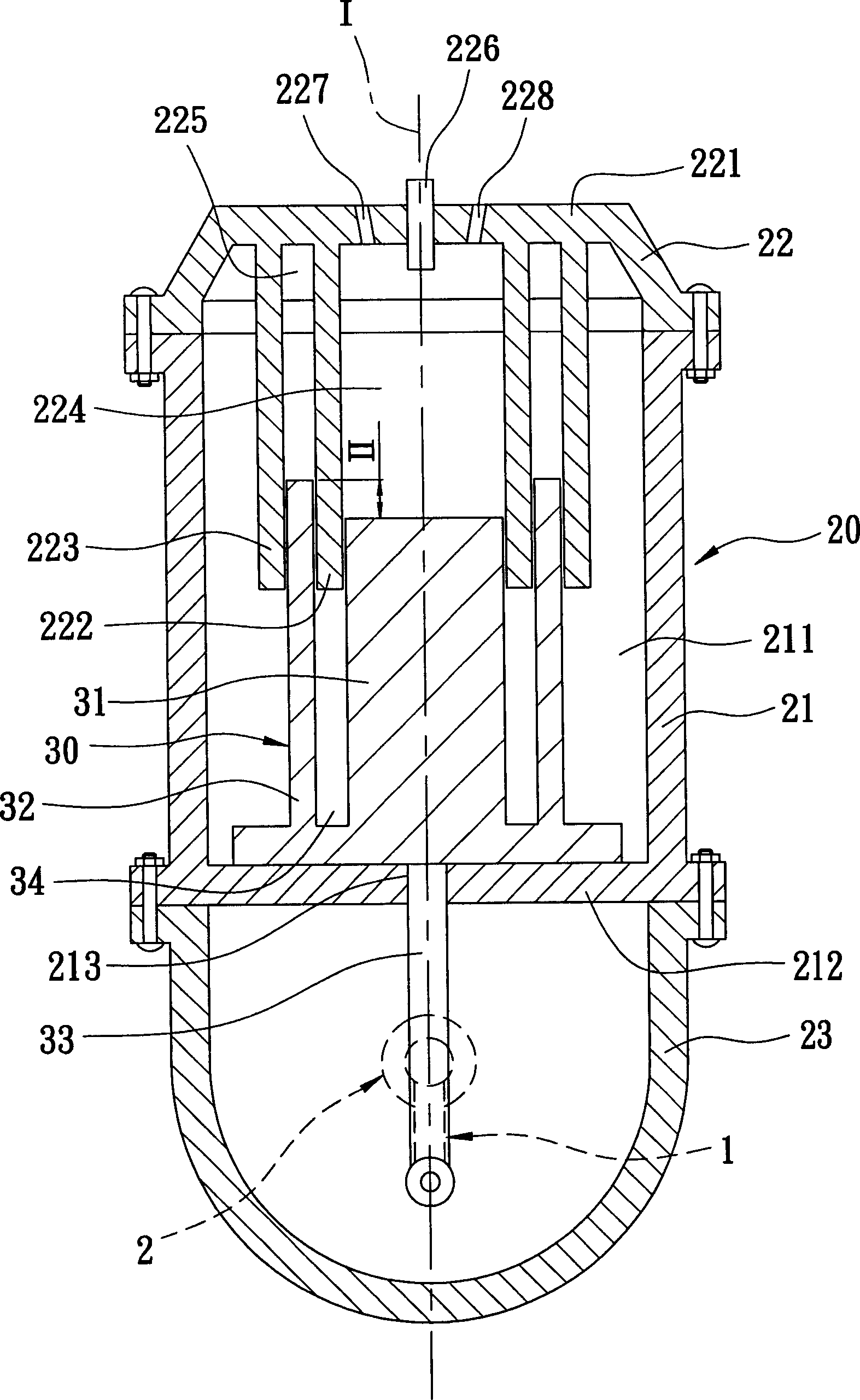

Non-friction air-compression and power generator

InactiveCN1896461AGuaranteed high speed operationSuppress high temperatureMulti-stage pumpsReciprocating piston enginesPistonEngineering

This is a kind of non-friction type air compressing, power generating device. It mainly includes a body element and a piston element. There is a partition wall in the body element. The partition wall encloses a piston air chamber. There are a central ring cover and a sidewall in the piston element. The central ring cover can enter into the piston air chamber. The sidewall is at the outer side of central ring cover. Air in the air chamber is compressed by partition wall to obstruct the air in the air chamber not to leak. Thus, it makes piston element can run up under null friction mode. It also does not generate high temperature.

Owner:林耀章

Vehicle

ActiveCN103032244BSimple configurationAvoid conductionCycle equipmentsEngine controllersElectricityVehicle frame

The invention provides a vehicle which controls accommodation space of wires into a minimum limit by shortening the length between a plurality of coils forming a rotary motor stator and a control unit, and allows the control unit to be compactly mounted on an engine. A two-wheeled motor vehicle (10A) is provided with a swinging unit (22) which is disposed on a vehicle frame (12) and comprises an engine (48). The engine (48) comprises a rotary motor (62) which comprises a stator (98) and an outer rotor (100) comprising a plurality of coils (110); a storage battery (20) electrically connected with the plurality of coils (110); a crankshaft (80) rotatably connected with the outer rotor (100) for rotation; and a control unit (68) which controls power current by switching on and off the connection of the plurality of coils (110) with the storage battery (20), and thus allows the rotary motor (62) to act as a motor or a generator. The control unit (68) is disposed near the rotary motor (62).

Owner:HONDA MOTOR CO LTD

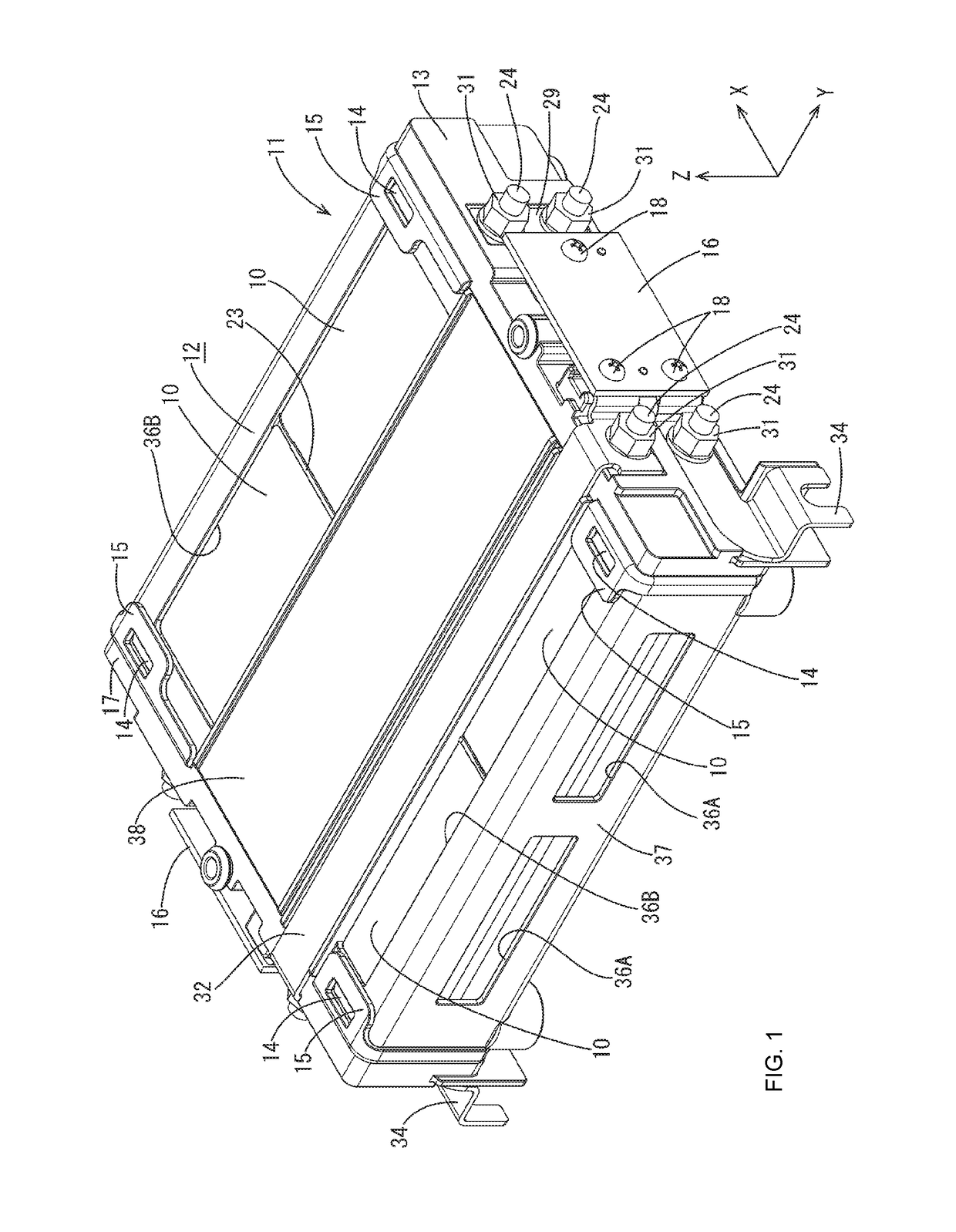

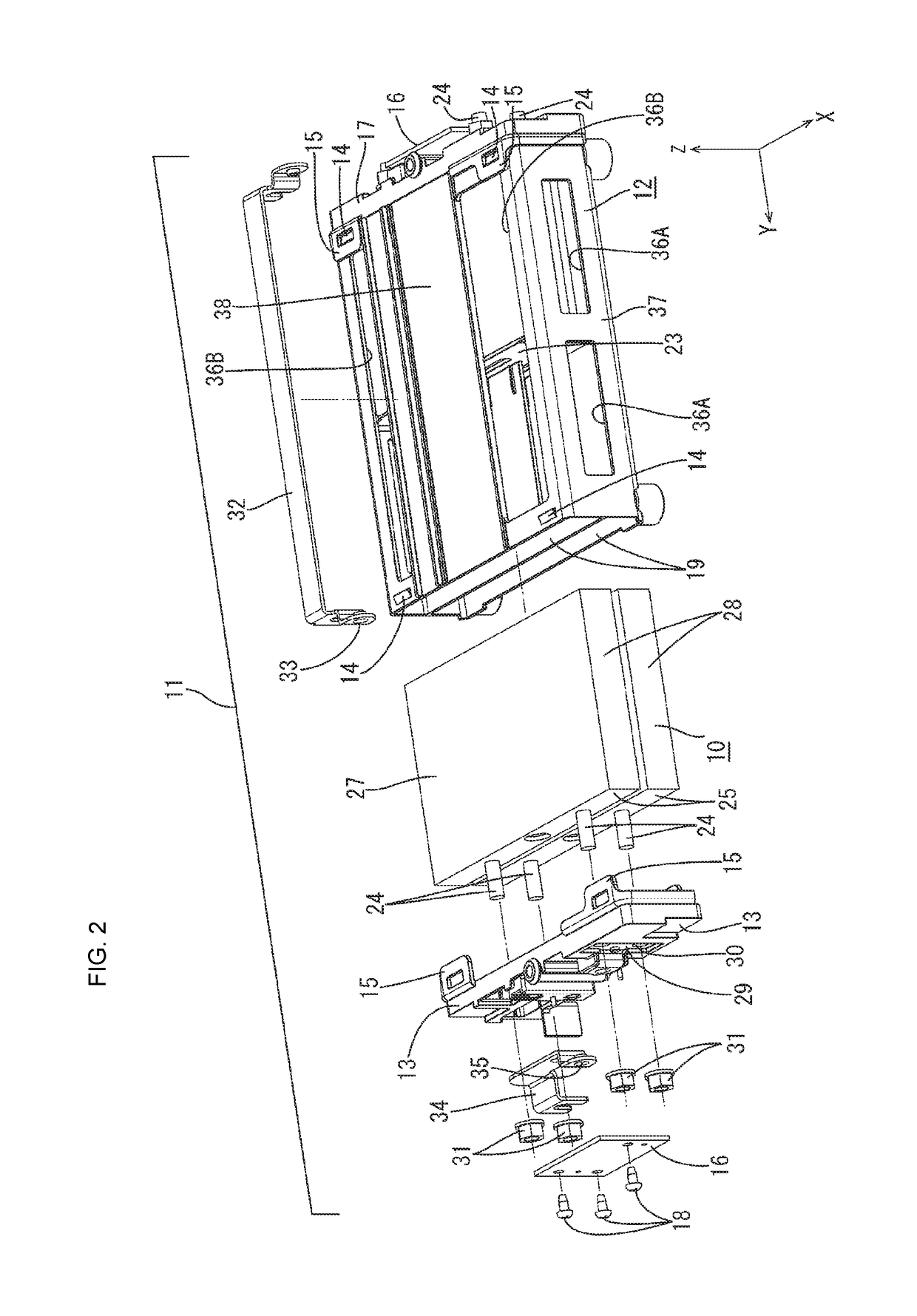

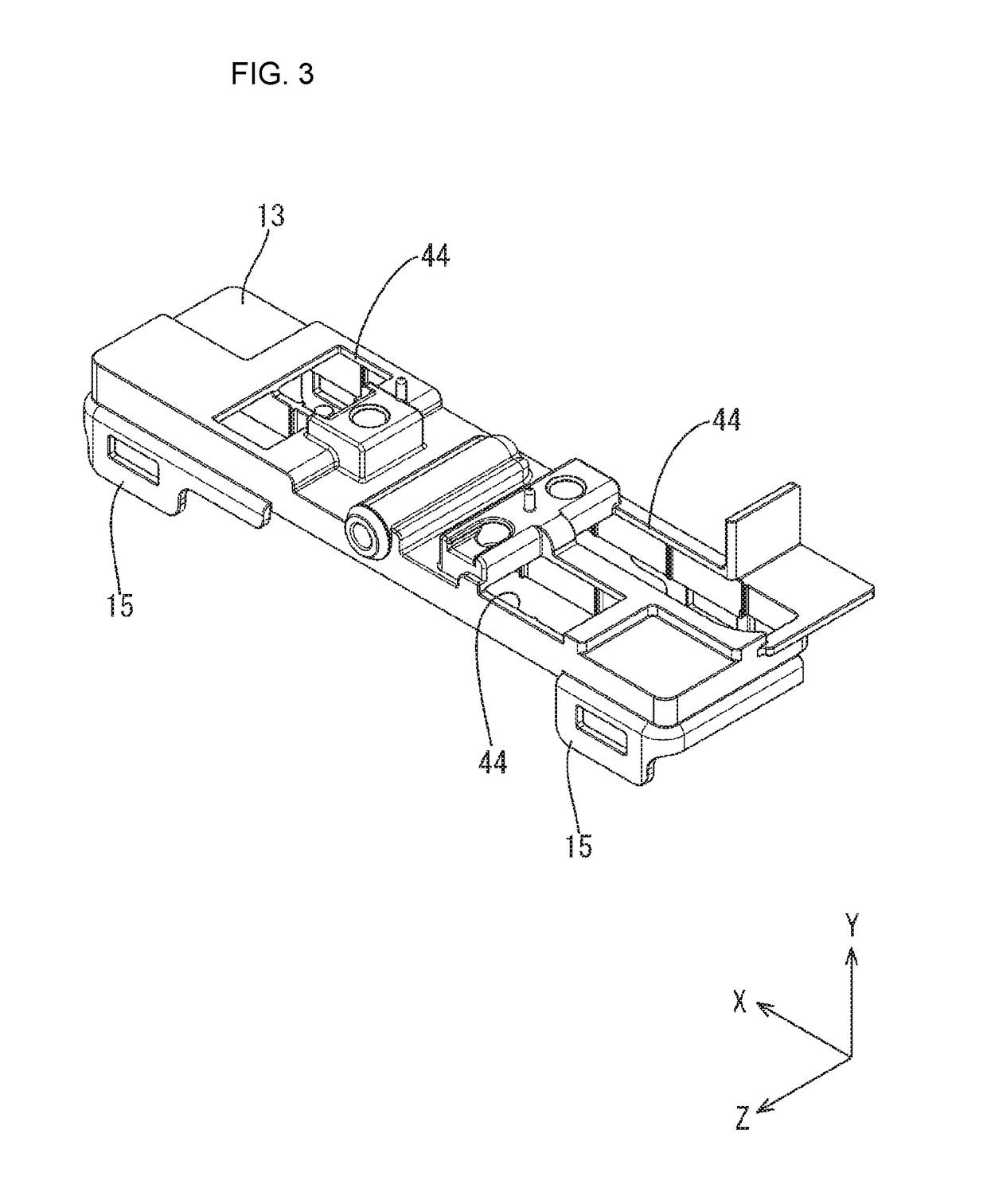

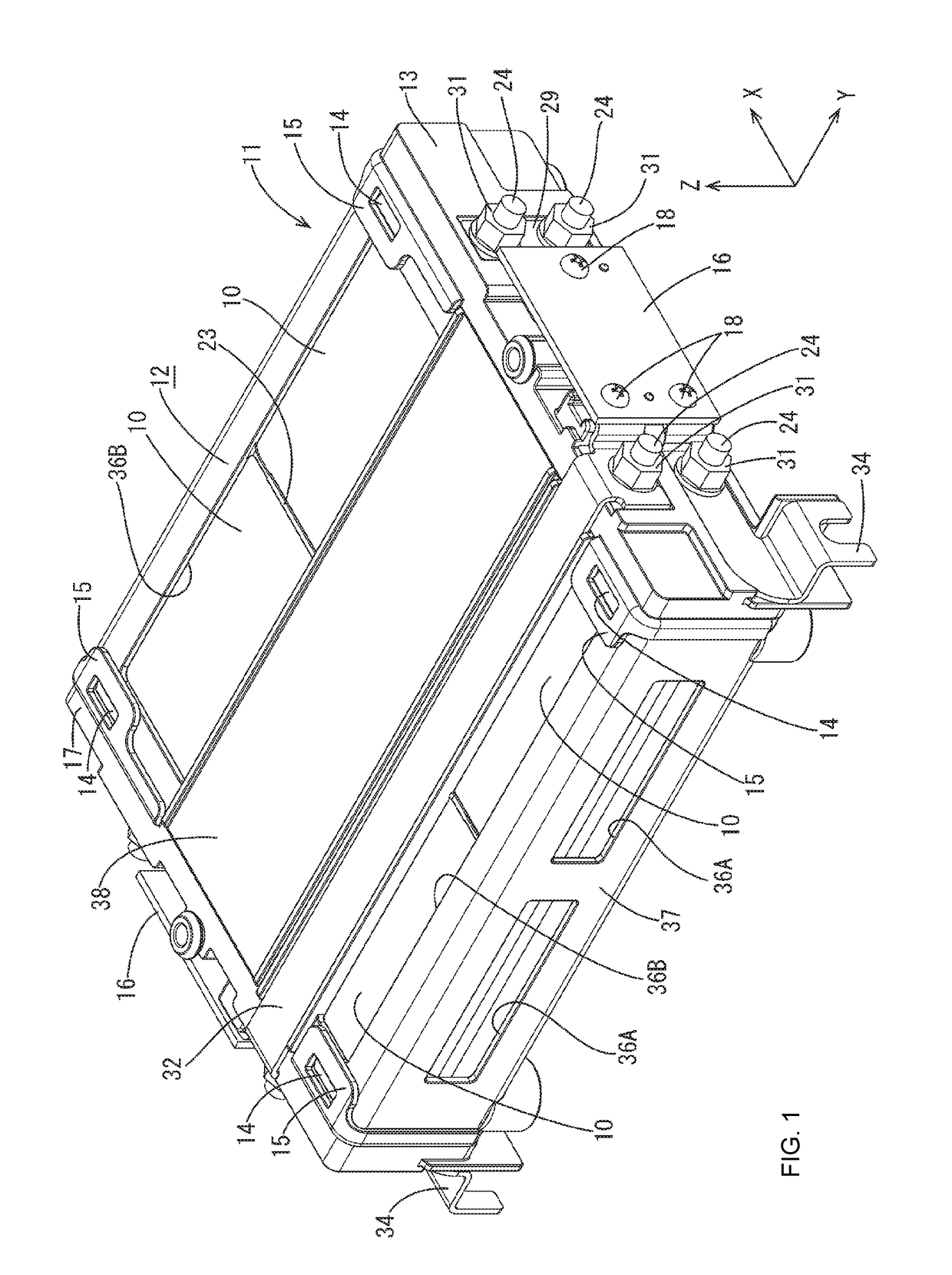

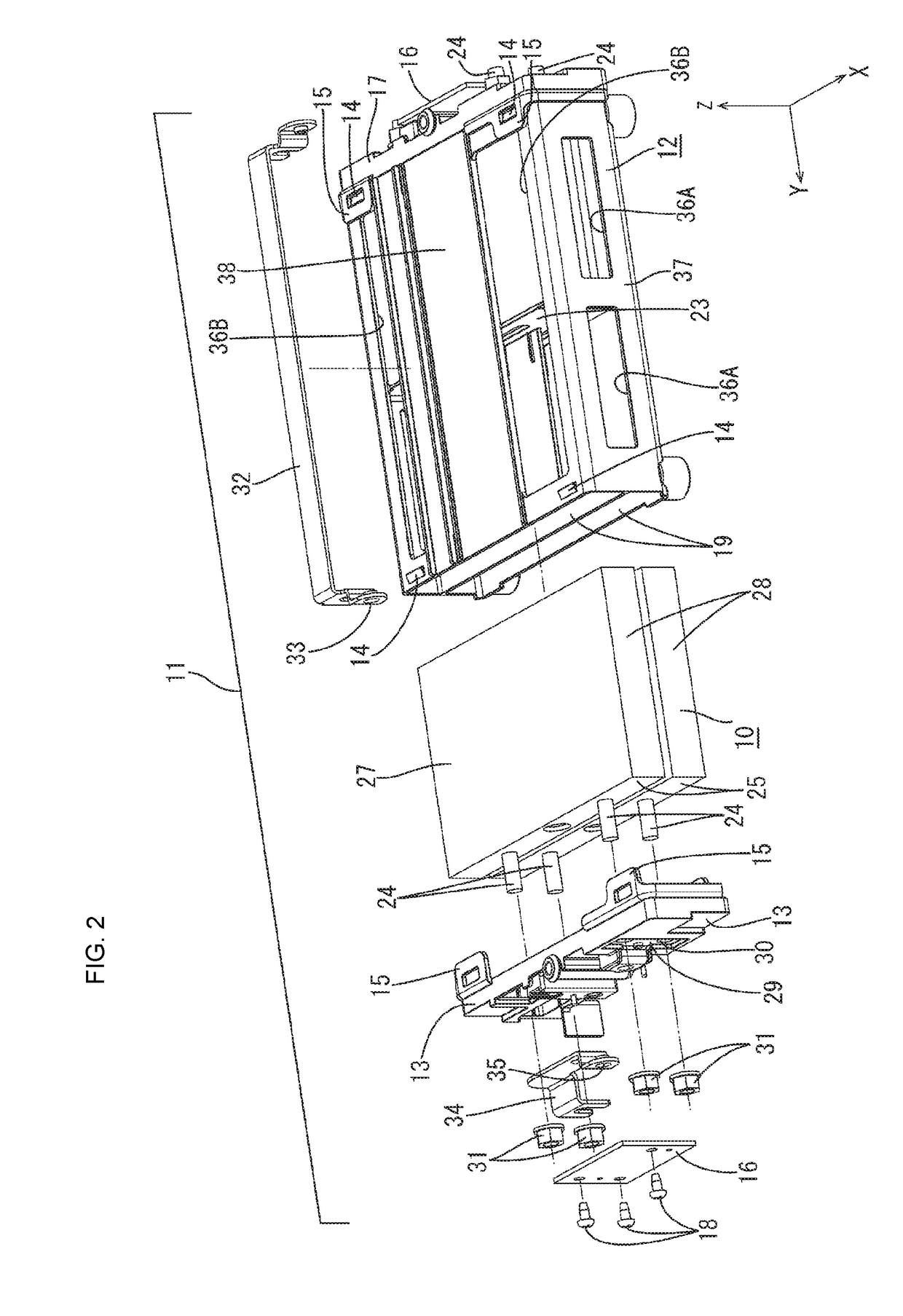

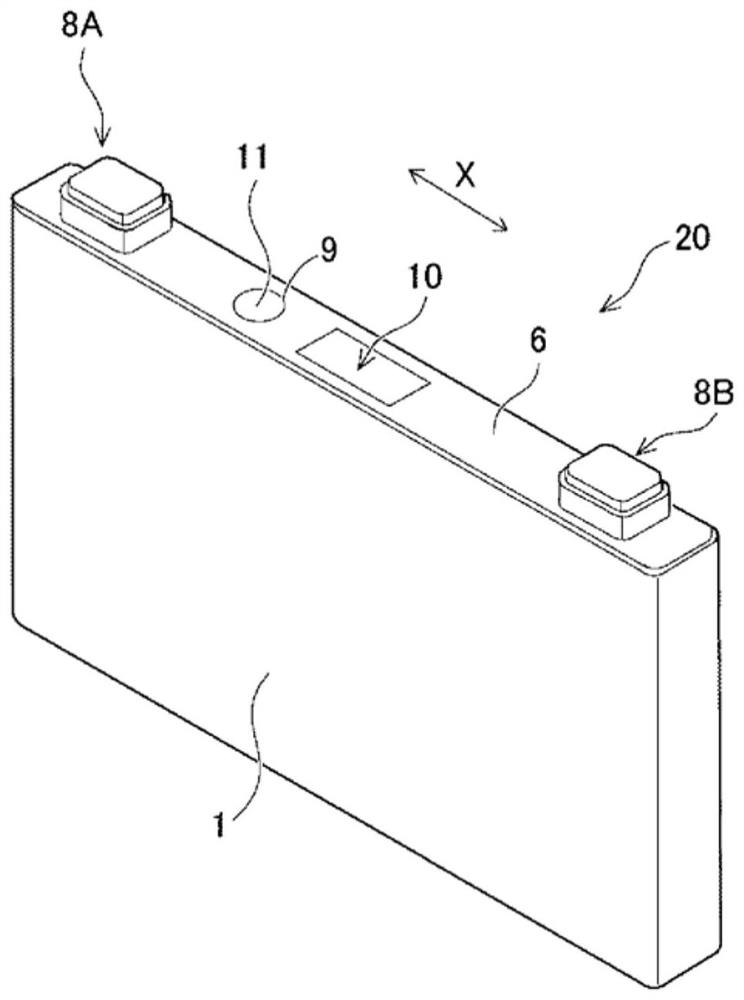

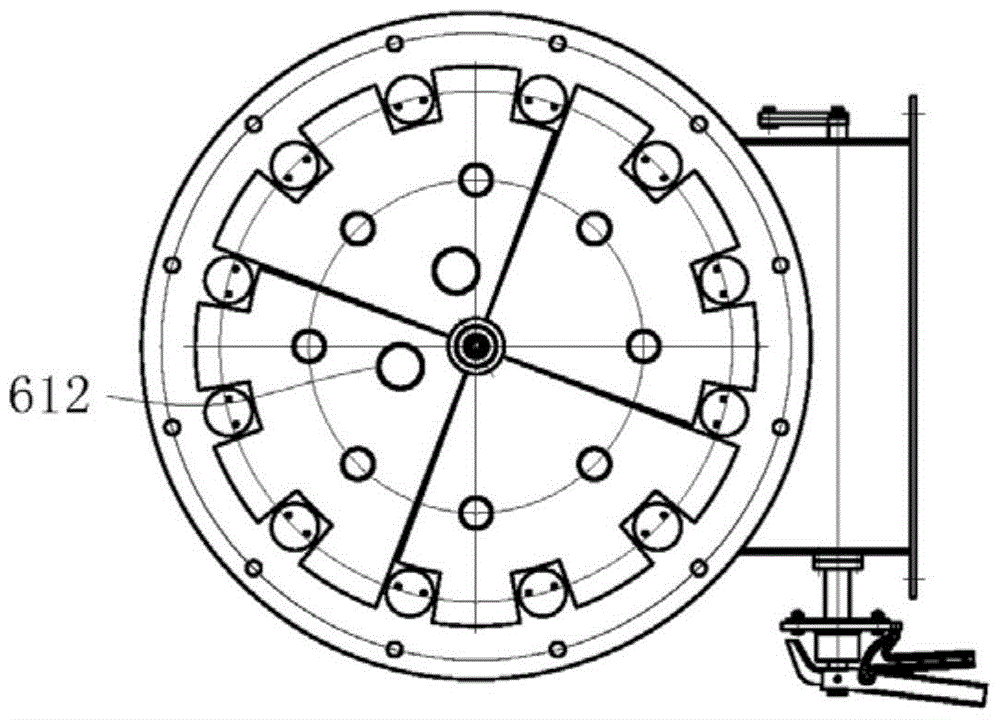

Electricity storage module

ActiveUS10236545B2Improve cooling effectReliable coolingProtecting/adjusting hybrid/EDL capacitorMultiple hybrid/EDL capacitorsElectricityMechanical engineering

An electricity storage module includes: multiple electricity storage elements; and a holding member formed by aligning multiple cavities in which the multiple electricity storage elements are stored, wherein an outer wall of the holding member has outer wall opening portions through which the multiple cavities communicate with the exterior, and outer surfaces of the multiple electricity storage elements stored in the multiple cavities are exposed to the exterior from the outer wall through the outer wall opening portions, and the holding member has a first cavity column in which cavities among the multiple cavities are aligned in two levels in an alignment direction, and a second cavity column in which cavities among the multiple cavities are aligned in two levels in the alignment direction at positions shifted in a direction intersecting with the alignment direction.

Owner:AUTONETWORKS TECH LTD +2

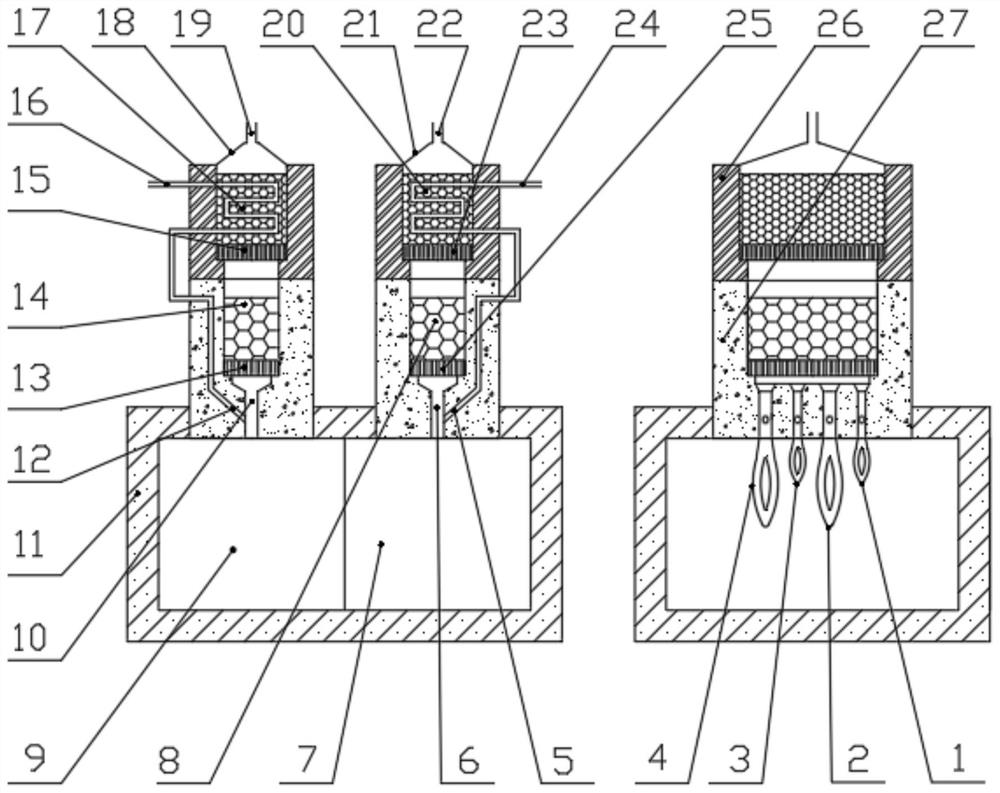

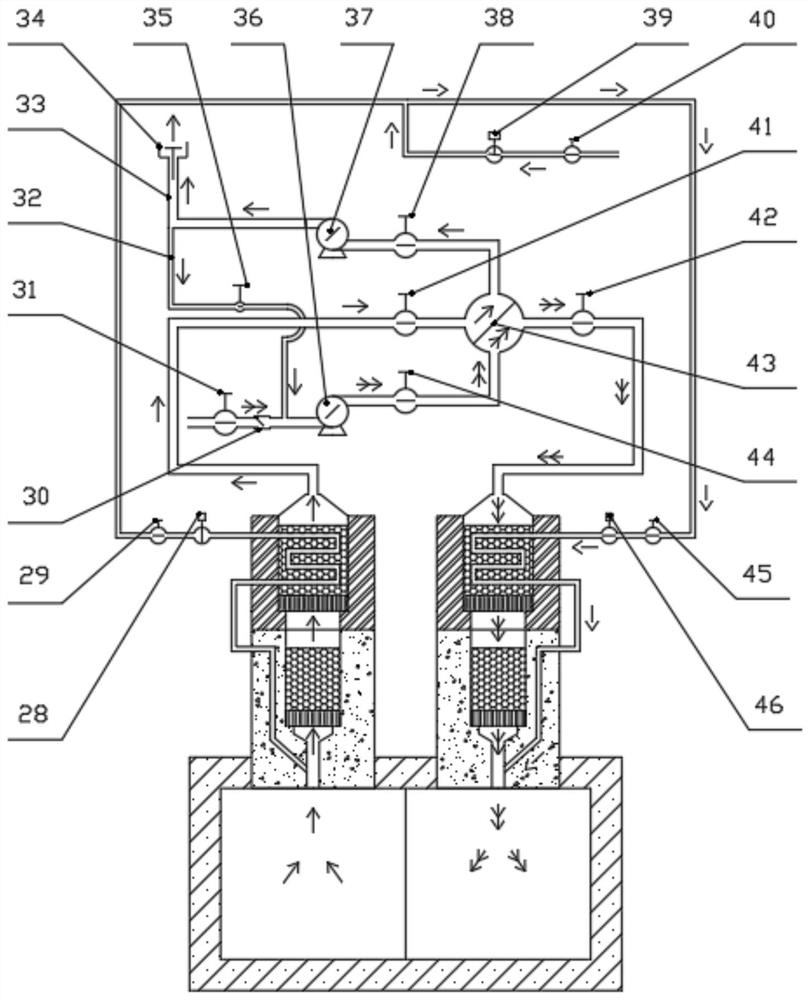

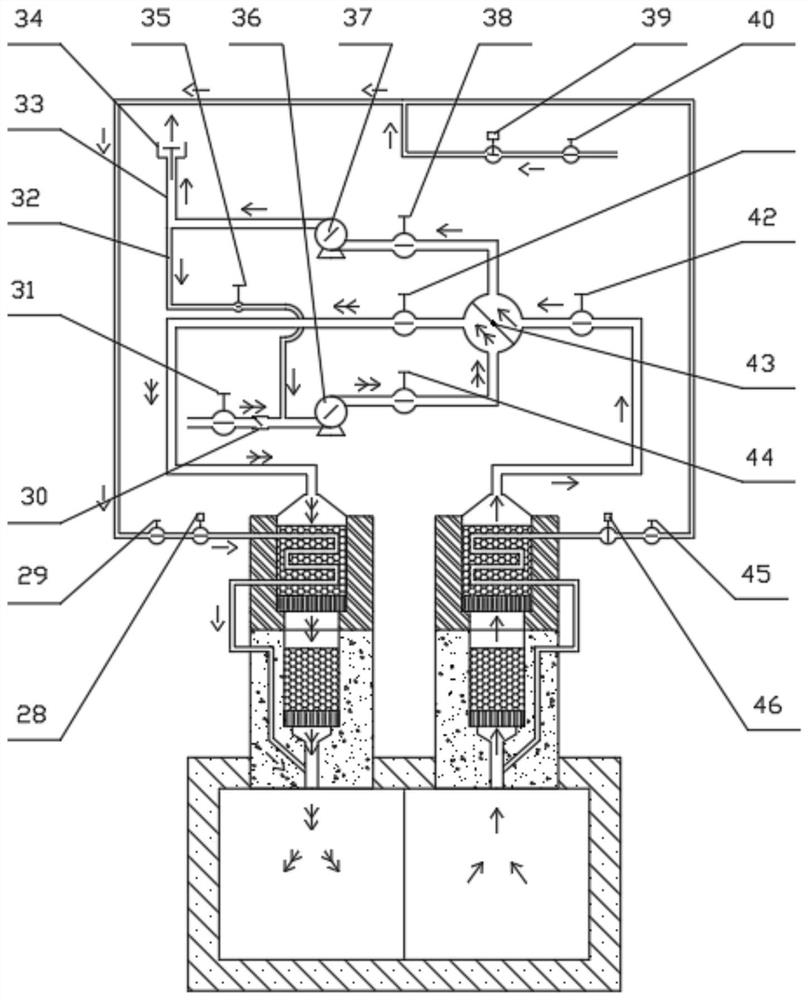

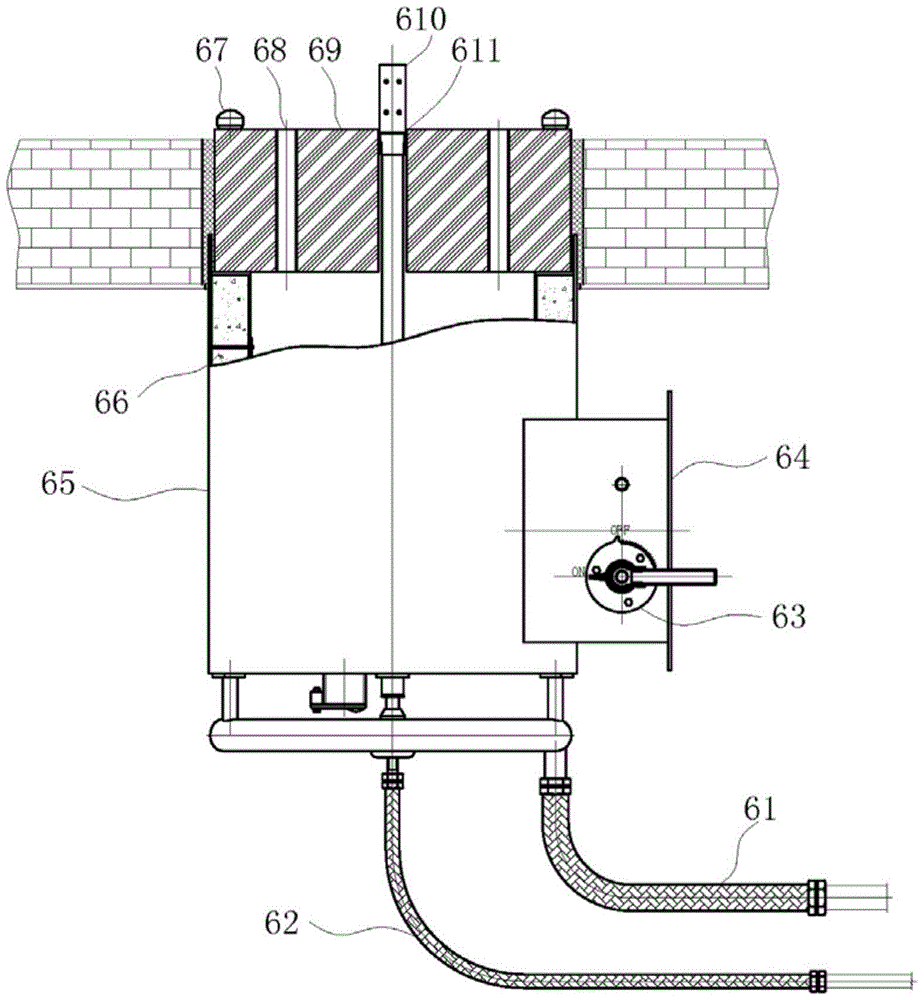

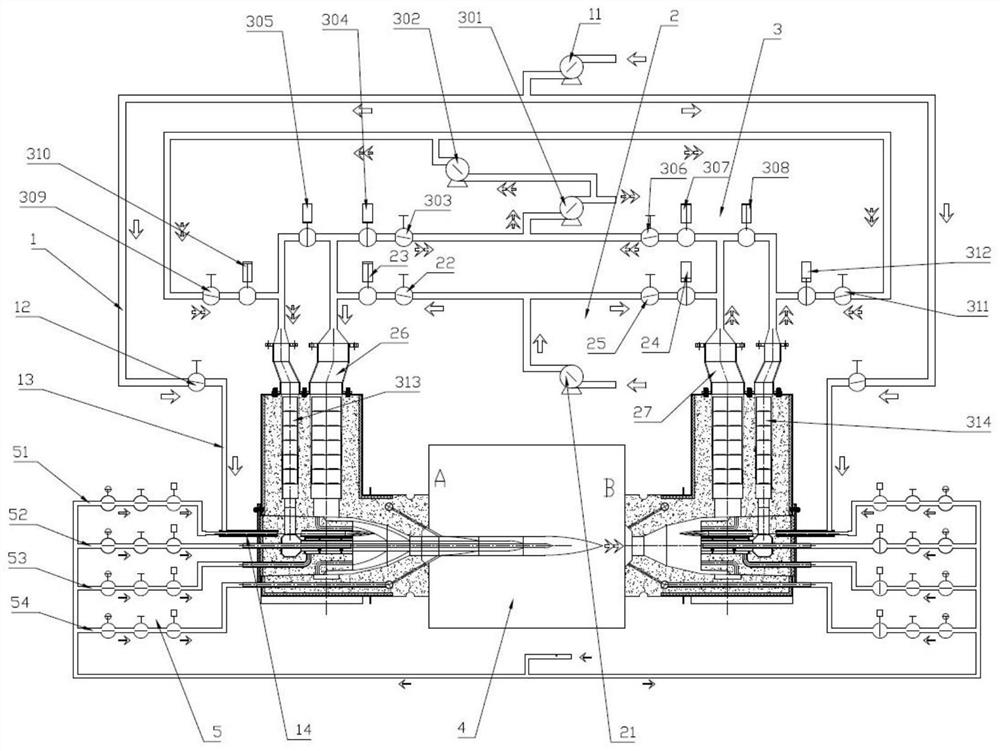

Low-nitrogen double-heat-storage natural gas burner

PendingCN112963835AHigh thermal efficiencySuppress high temperatureHeat storage plantsGaseous fuel burnerThermodynamicsProcess engineering

The invention provides a low-nitrogen double-heat-storage natural gas burner, and relates to the field of industrial heating furnace burners. The low-nitrogen-based double-heat-storage natural gas burner comprises a furnace body, wherein the interior of the furnace body is divided into a hearth area B and a hearth area A, two high-temperature heat storage chambers are symmetrically arranged at the top of the furnace body and communicated with the hearth area B and the hearth area A correspondingly, and medium-temperature heat storage chambers are fixedly connected to the tops of the two high-temperature heat storage chambers correspondingly. According to the low-nitrogen double-heat-storage natural gas burner, the heating technology is further optimized, the gap between energy conservation, emission reduction and the like and the international advanced level is reduced, and the development of a heating furnace has a sustainable development road with high technological content, good economic benefit, low energy consumption and less environmental pollution.

Owner:SHANDONG YIRAN ENVIRONMENTAL PROTECTION TECH CO LTD

Anti-explosion tank

ActiveCN101844657BAntiknock equivalentStrong anti-knock abilityLarge containersEngineeringExplosive material

The invention relates to an anti-explosion tank which belongs to the field of anti-explosion equipment. A high polymer energy-absorbing material is adopted as a buffer layer in the invention, and a fire-extinguishing liner is configured on the inner wall of an inner barrel, thereby not only the weight of a tank body can be lightened, but also high temperature and flames generated by explosion canbe effectively inhabited, thereby solving the defects of heavy tank body, maneuverability lack and the like existing in a traditional anti-explosion tank and the problems of difficult inhabitation ofhigh temperature and flames generated by explosion. The anti-explosion tank comprises a top cover, a seal ring, the fire-extinguishing liner, the inner barrel, the buffer layer, an outer barrel, a foaming material layer, a shell and a truckle, wherein the inner barrel, the outer barrel and the buffer layer form three layers of protection, thereby the protecting capability is improved, and the personnel and property safety can be ensured. The invention is mainly used for tank-shaped equipment which is flexibly moved and conveniently transferred and used for temporarily storing or transporting explosive substances.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +2

power supply

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

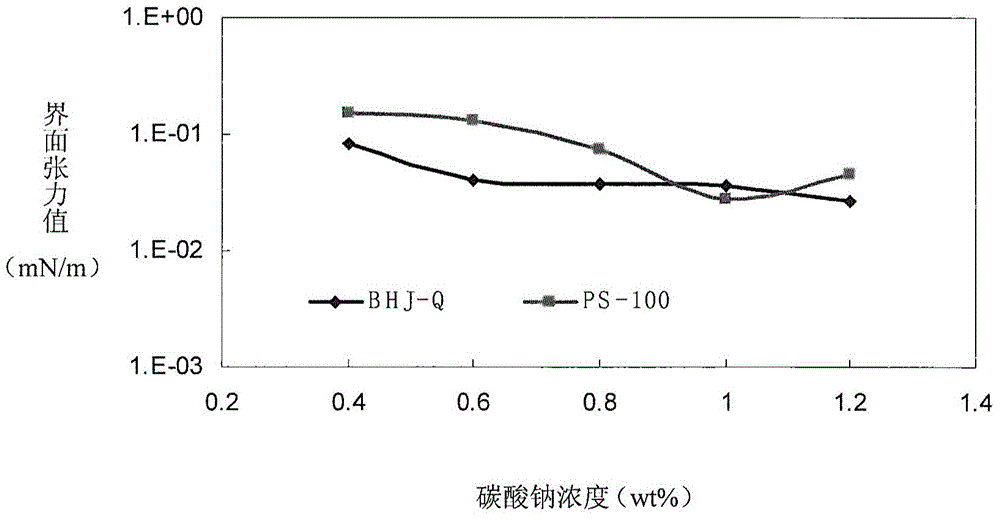

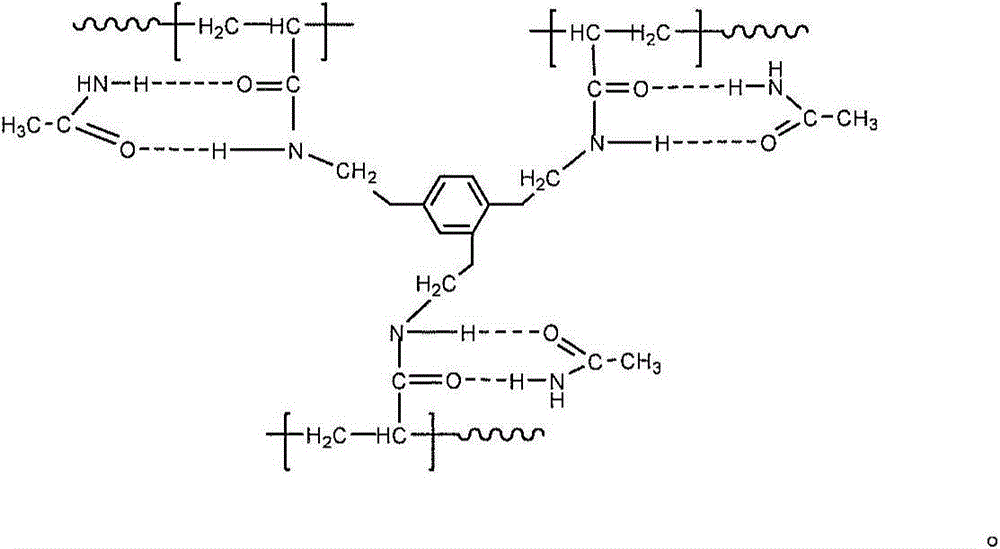

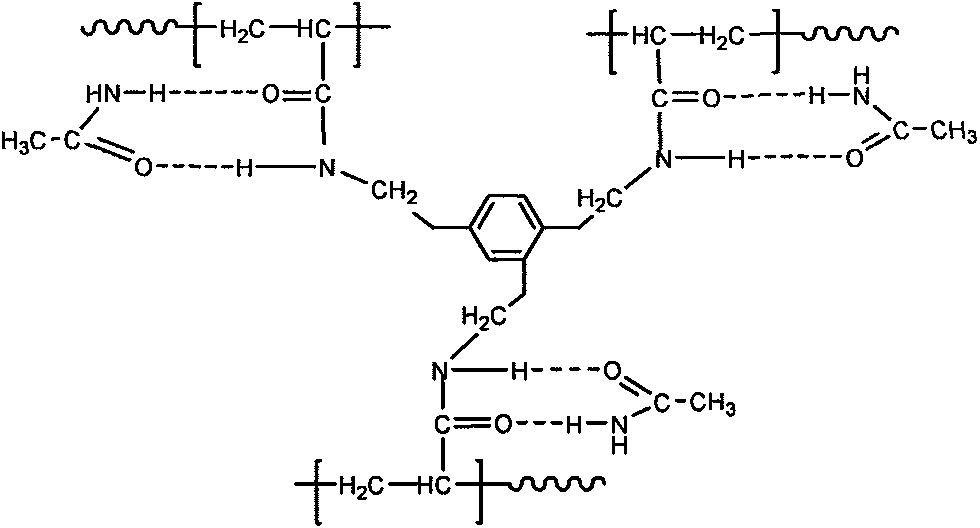

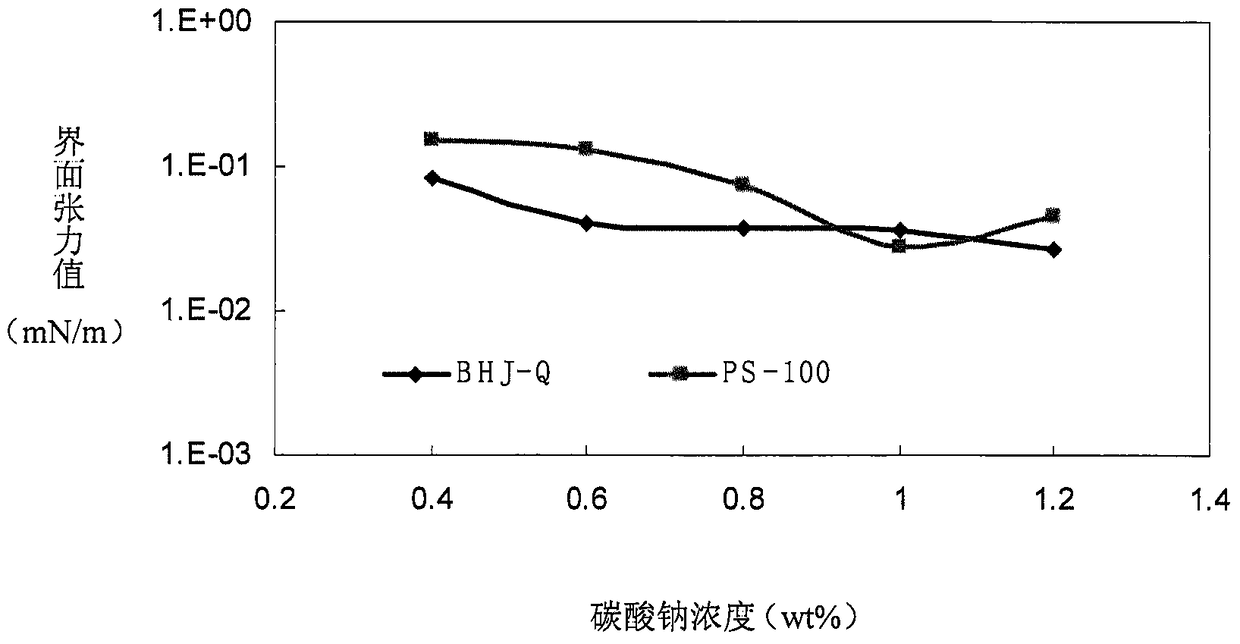

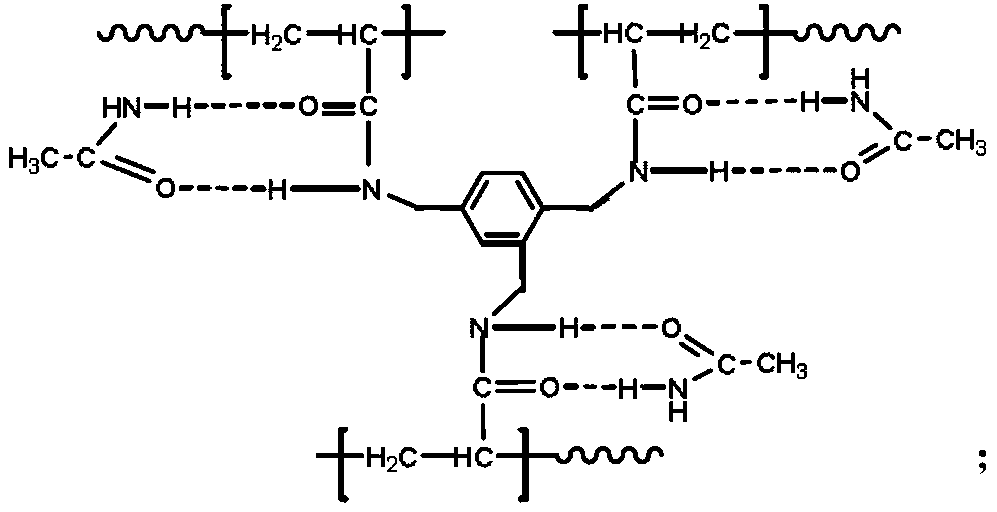

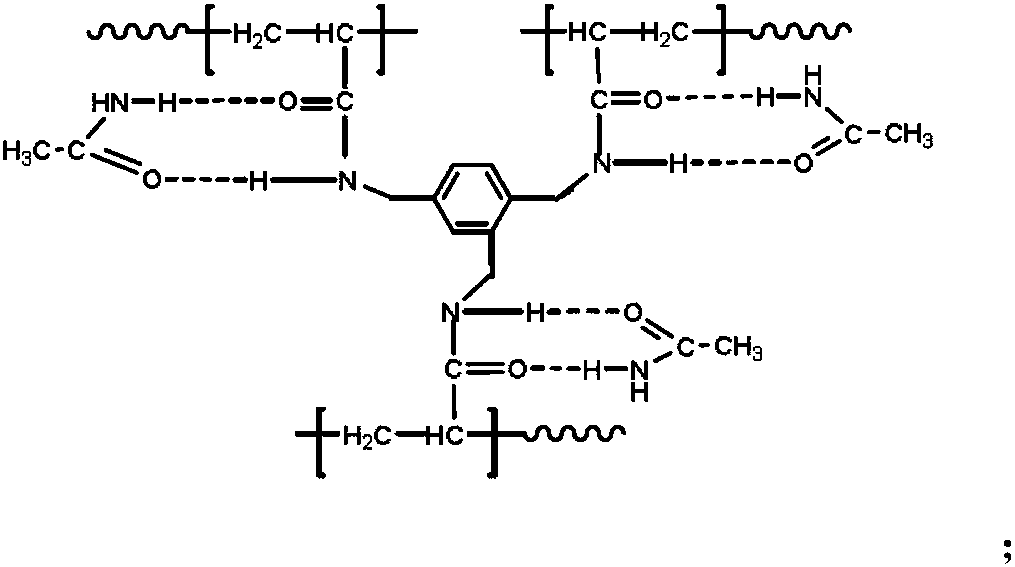

Polymer suitable for high-temperature and high-salinity oil deposits and preparation method of polymer

ActiveCN104892802AGood chemical stabilityImprove salt toleranceFluid removalDrilling compositionPolymer scienceStructural formula

The invention discloses a polymer suitable for high temperature and high salinity oil deposits and a preparation method of the polymer. The chemical structural formula of the polymer is shown in the description. The polymer has a net structure and is capable of effectively inhibiting high temperature and oxidative degradation, thus effectively improving salt resistance and enhancing viscosity increasing capacity. After the polymer disclosed by the invention is introduced into a ternary compound system, the ternary compound system has good chemical stability and excellent salt resistance under high temperature and high salinity conditions, the interfacial tension of crude oil / formation water is reduced to ultra low under weak base and sodium carbonate conditions, the recovery ratio can be increased by 20% or more, and thus the obtained ternary compound system can be applied to extremely high temperature and high mineralized oil deposits.

Owner:PETROCHINA CO LTD +1

Electricity storage module

ActiveUS20170324131A1Reliable coolingImprove cooling effectProtecting/adjusting hybrid/EDL capacitorMultiple hybrid/EDL capacitorsElectricityPosition shift

An electricity storage module includes: multiple electricity storage elements; and a holding member formed by aligning multiple cavities in which the multiple electricity storage elements are stored, wherein an outer wall of the holding member has outer wall opening portions through which the multiple cavities communicate with the exterior, and outer surfaces of the multiple electricity storage elements stored in the multiple cavities are exposed to the exterior from the outer wall through the outer wall opening portions, and the holding member has a first cavity column in which cavities among the multiple cavities are aligned in two levels in an alignment direction, and a second cavity column in which cavities among the multiple cavities are aligned in two levels in the alignment direction at positions shifted in a direction intersecting with the alignment direction.

Owner:AUTONETWORKS TECH LTD +2

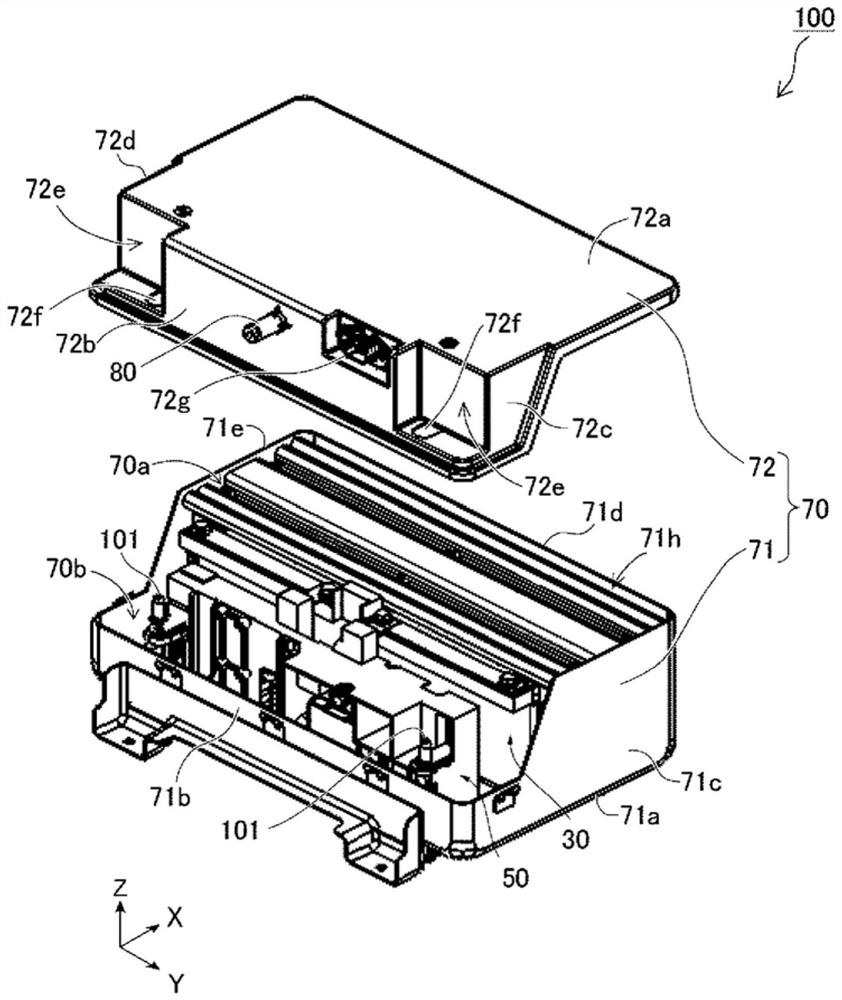

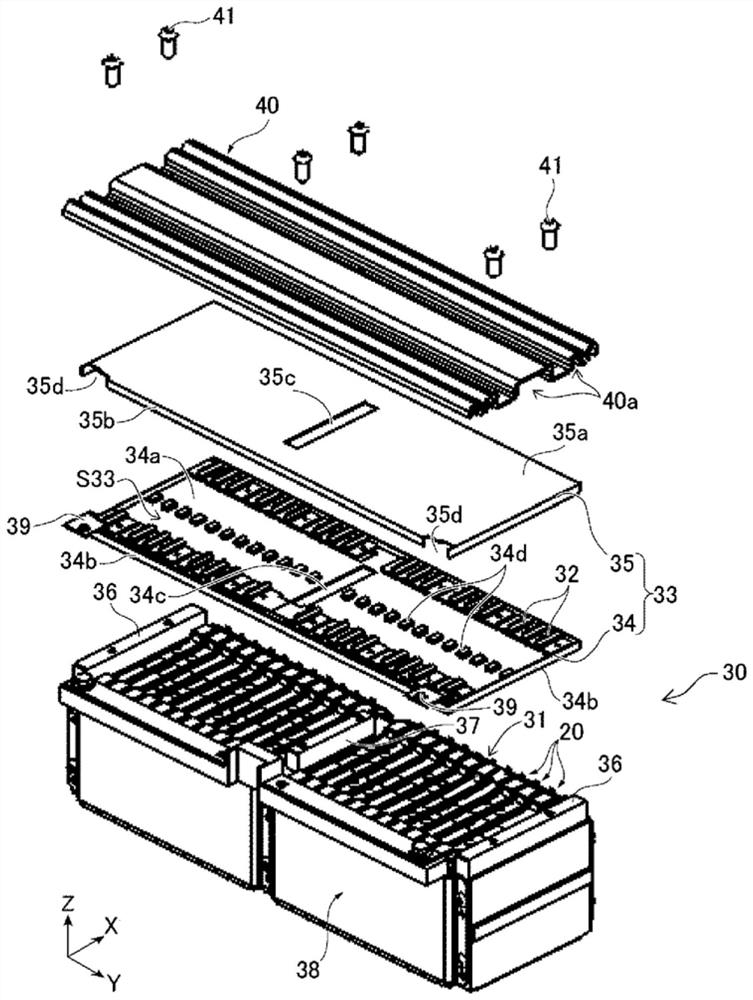

Battery pack

PendingCN114223091ASuppress high temperatureVent arrangementsCell lids/coversThermodynamicsMechanical engineering

The invention provides a battery pack which can prevent other battery cells from becoming high temperature due to gas discharged from the battery cells and store the gas in the battery pack as much as possible. This battery pack (100) is provided with a battery module (30), an electric unit (50), and a case (70). A first housing space (70a) for housing a battery module (30) and a second housing space (70b) for housing an electric unit (50) are provided inside a case (70), a duct (80) for communicating the second housing space (70b) and the outside of the case (70) is provided in a portion of the case (70) forming the second housing space (70b), and a filter (91) for closing a gas passage (80a) of the duct (80) is provided on the duct (80). The filter (91) opens the gas passage (80a) of the duct (80) when the gas pressure in the second housing space (70b) becomes equal to or greater than a predetermined value with respect to the gas pressure outside the housing (70).

Owner:日本汽车能源株式会社

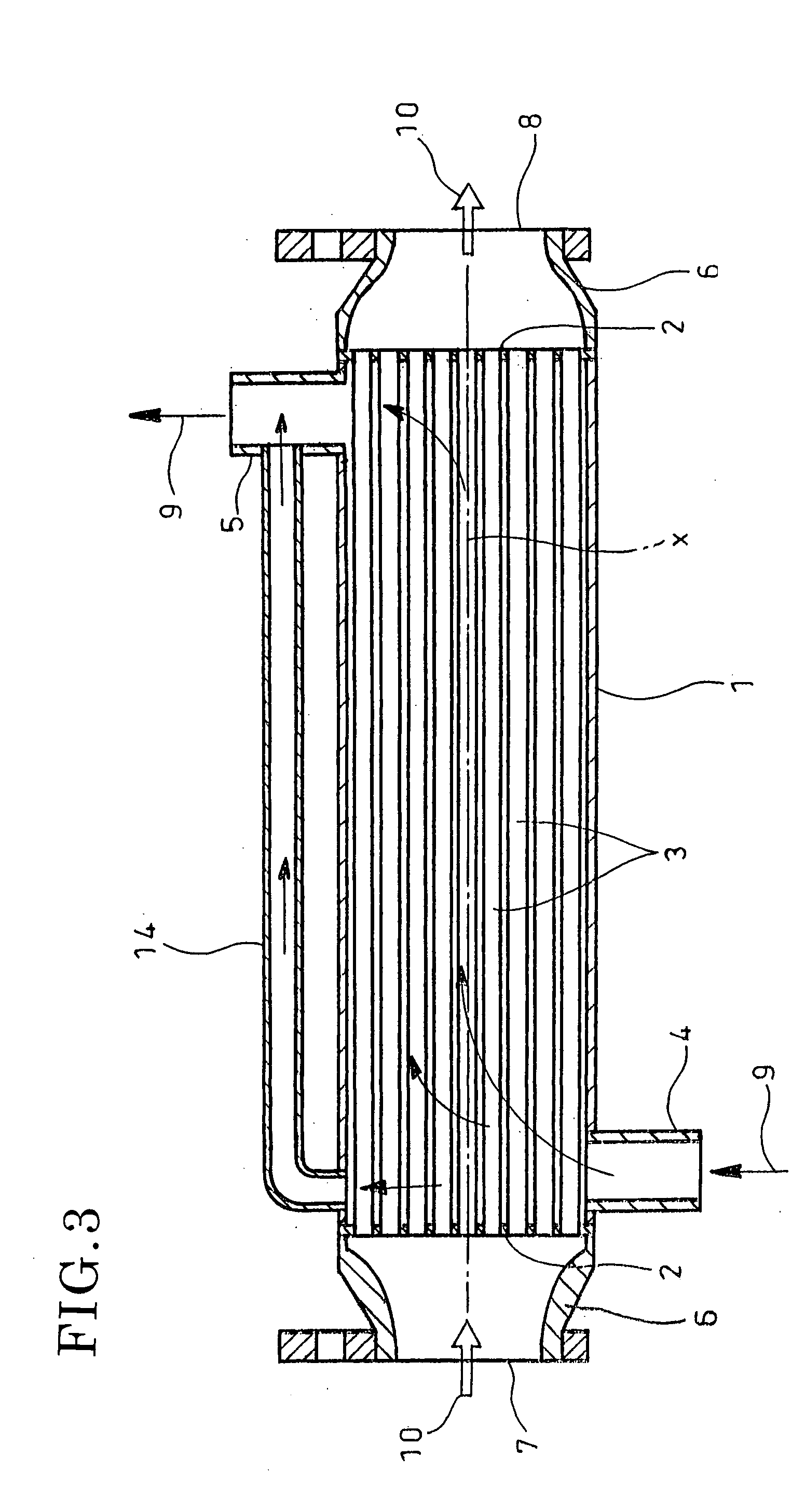

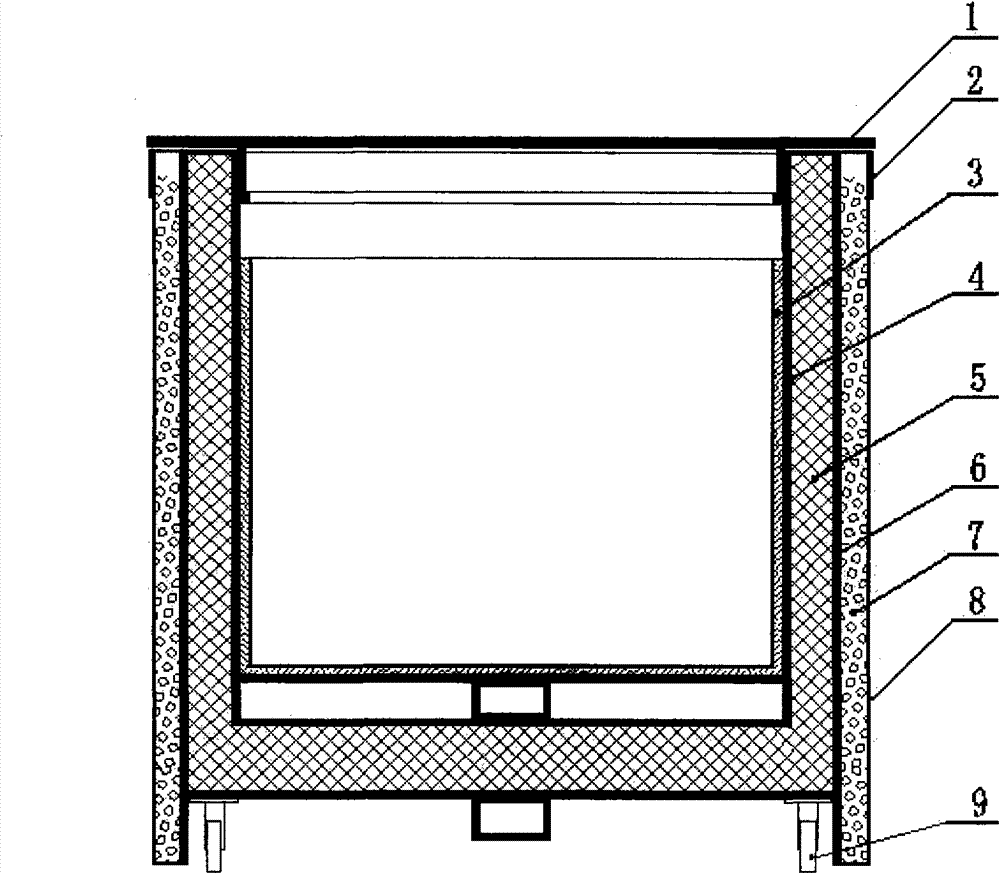

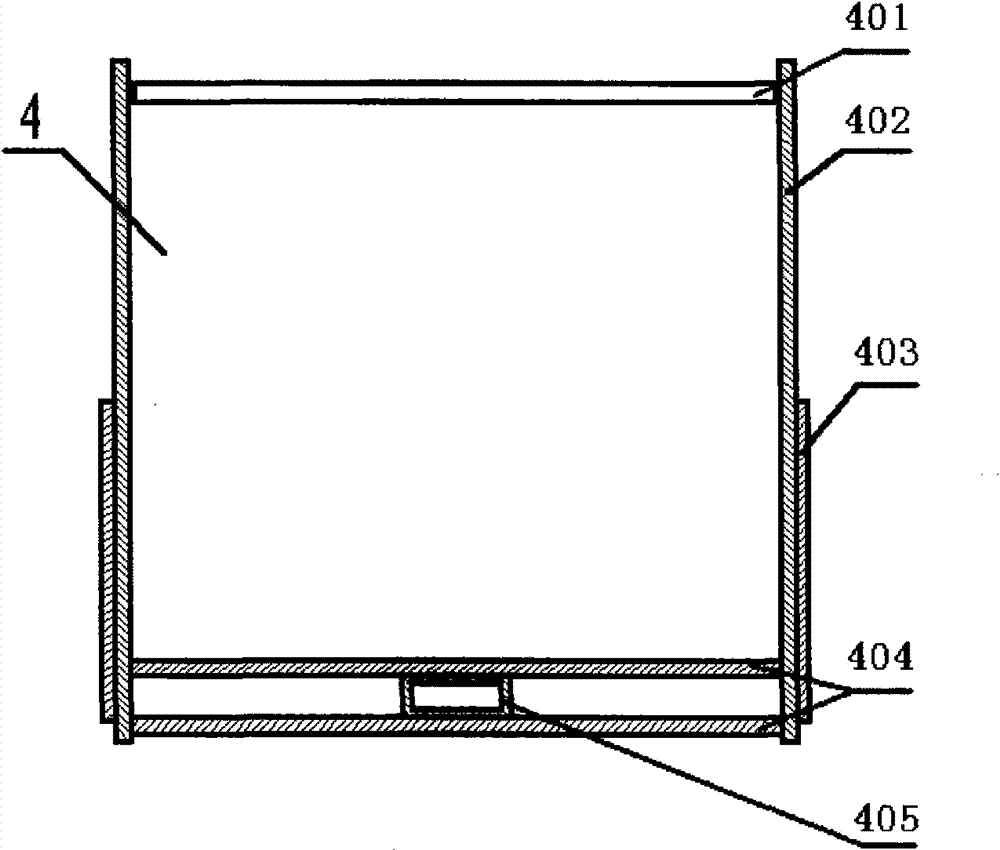

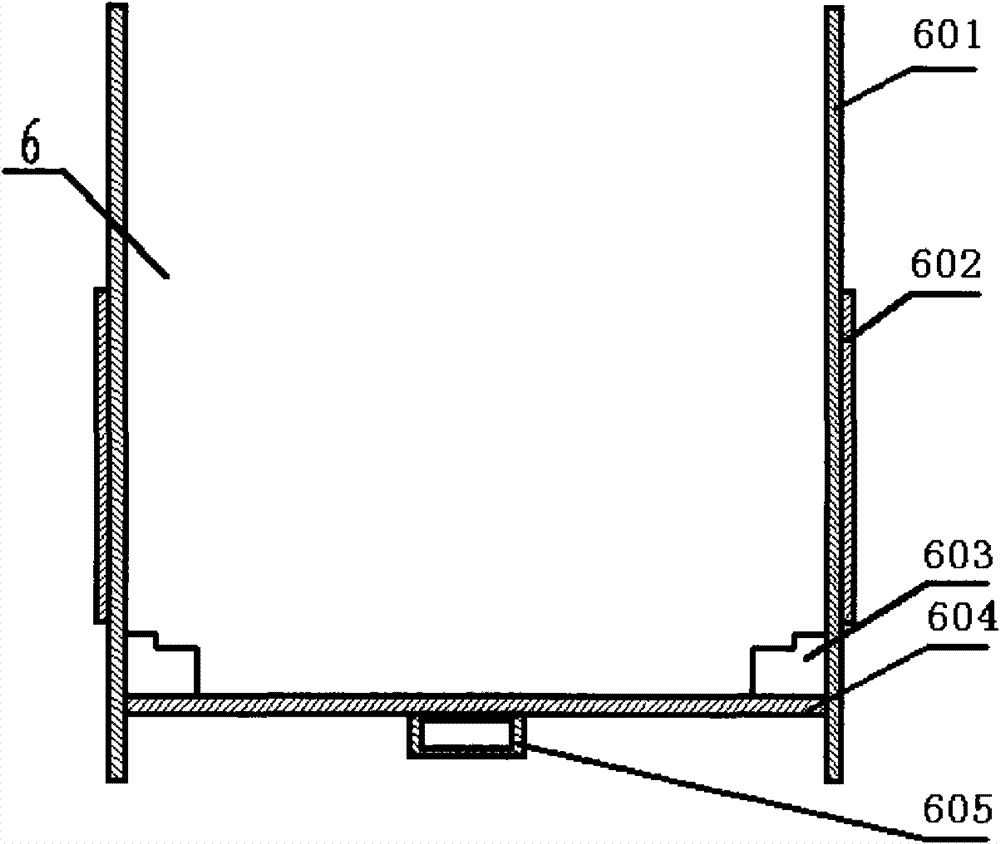

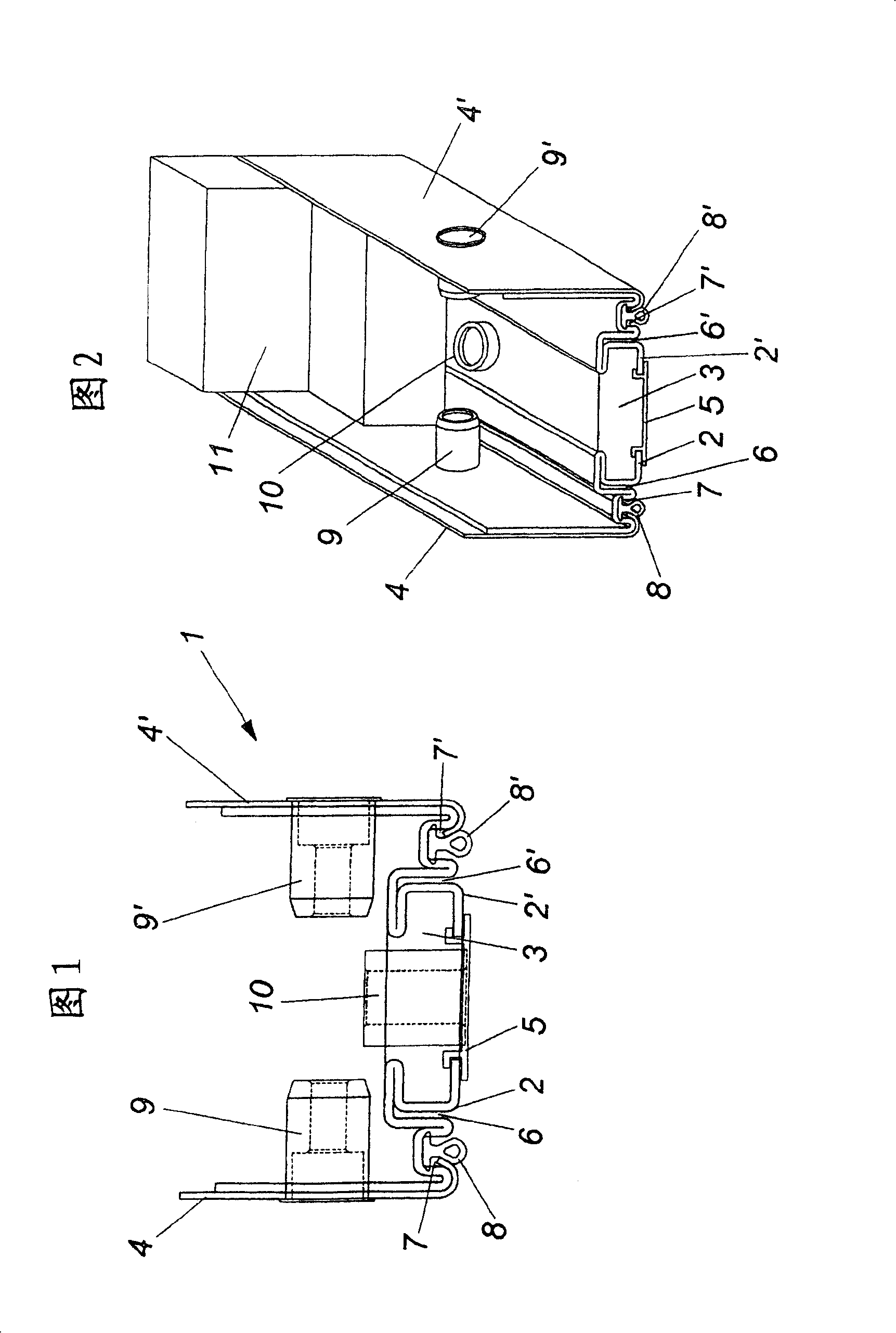

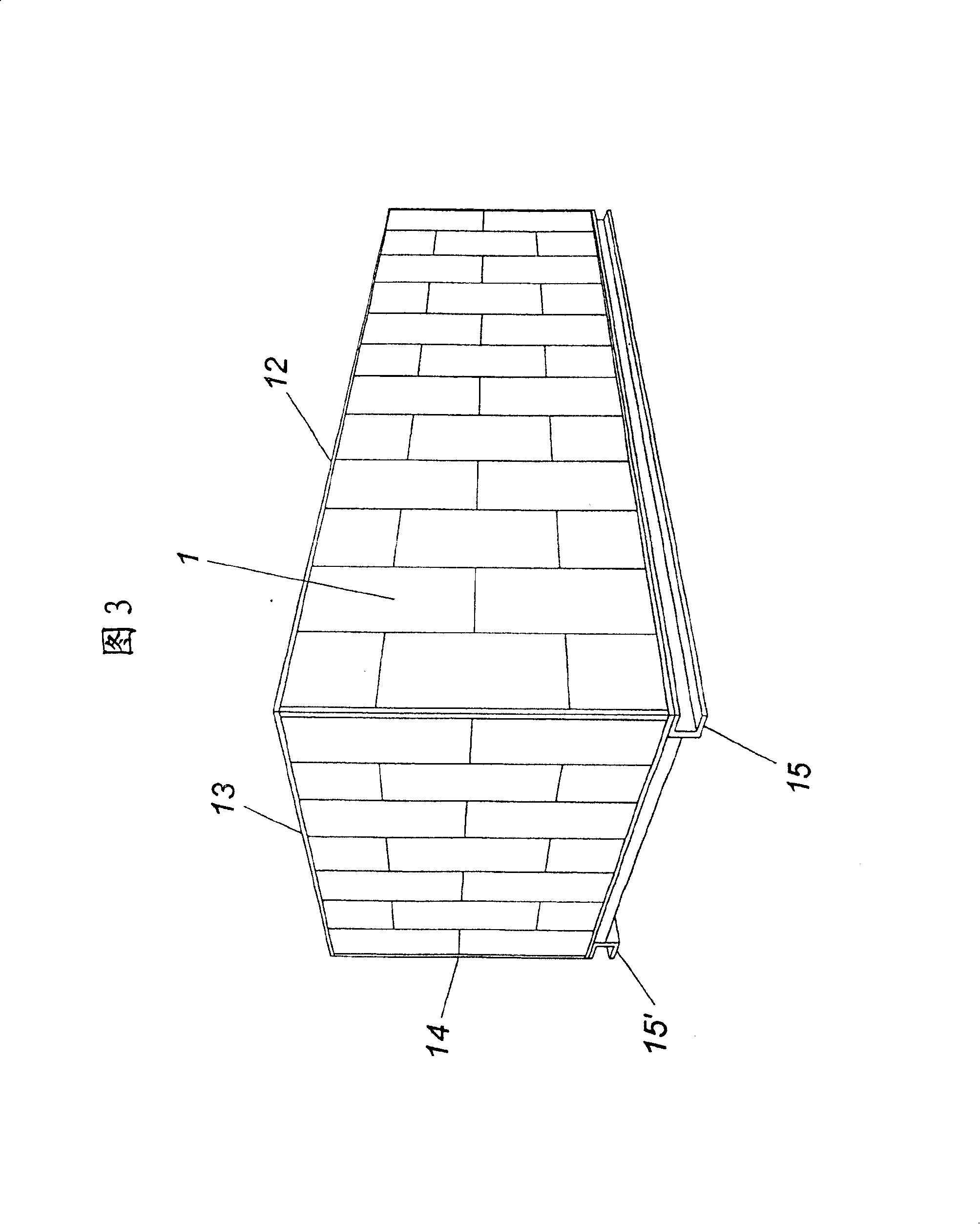

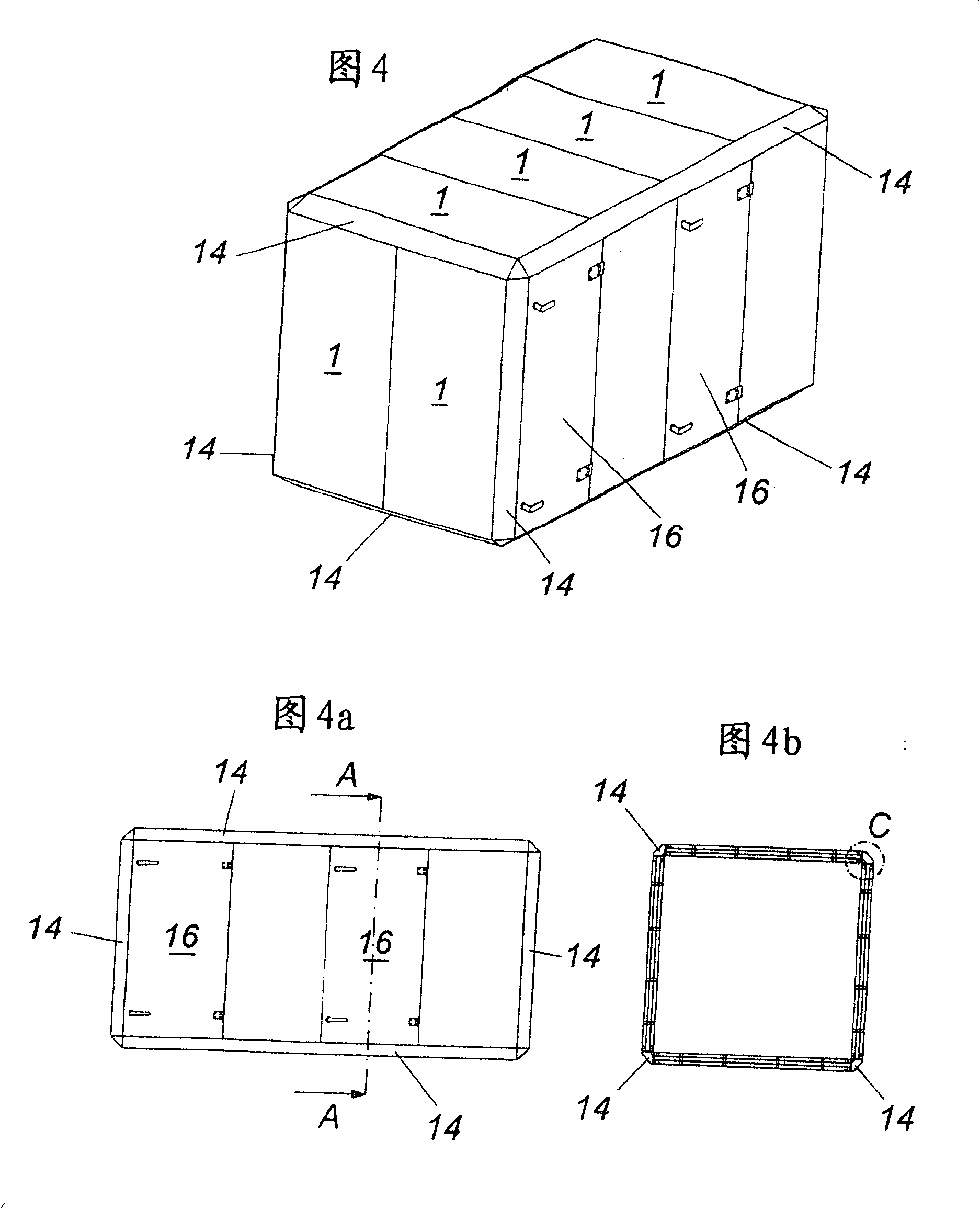

Panel for modular housing construction in particular of ventilating and air conditioning plants

InactiveCN100398933CFixedAchieve stabilityHeating and ventilation casings/coversHeat proofingInsulation layerAir conditioning

The plate element (1) for modular construction, in particular, for the crate of ventilation equipment or an air conditioner is provided in the present invention. The plate element has two parallel side walls (4, 4') having a distance between them and a heat insulation layer (11) between the two side walls, and an end surface distributed with a ring plate element (1) vertical to the side walls (4, 4'), wherein, the transverse section of the end surface having two metal sections (2, 2') between which a distance exists and a heat insulation material (3) is positioned between the two metal sections.

Owner:EUROCLIMA APPBAU

A ternary composite system suitable for high temperature and high salinity reservoirs and its preparation method

ActiveCN105038754BGood chemical stabilityImprove salt toleranceFluid removalDrilling compositionSalt resistanceChemical structure

The present invention discloses a ternary composite system suitable for high-temperature and high-salinity oil reservoir, and a preparation method thereof. The ternary composite system comprises a polymer, a surfactant and sodium carbonate, wherein the chemical structure formula of the polymer is defined in the specification, and the polymer has a network structure and has the effect of effective inhibition of high temperature and oxidation degradation so as to effectively improve salt resistance and strengthen thickening capacity. According to the present invention, after the polymer is introduced into the ternary composite system, the ternary composite system has good chemical stability and excellent salt resistance under the conditions of high temperature and high salinity, makes the crude oil / stratum water interface tension be reduced to an ultra-low level under the weak base sodium carbonate condition, and can improve the recovery rate by more than or equal to 20%, such that the ternary composite system of the present invention can be used for the extreme high-temperature and high-salinity oil reservoir conditions.

Owner:PETROCHINA CO LTD +1

A polymer suitable for high temperature and high salinity oil reservoirs and its preparation method

ActiveCN104892802BGood chemical stabilityImprove salt toleranceFluid removalDrilling compositionChemical structurePolymer science

The invention discloses a polymer suitable for high temperature and high salinity reservoirs and a preparation method thereof. The chemical structural formula of the polymer is as follows:. The polymer has a network structure, which can effectively inhibit high temperature and oxidative degradation, thereby effectively improving salt resistance and enhancing viscosity. After the polymer of the present invention is introduced into the ternary composite system, the ternary composite system has good chemical stability and excellent salt resistance under conditions of high temperature and high salinity, and can be used under the condition of weak alkali sodium carbonate The interfacial tension of crude oil / formation water is reduced to ultra-low, and the recovery rate can be increased by more than 20%, so that the obtained ternary composite system can be applied to extreme high temperature and high salinity reservoir conditions.

Owner:PETROCHINA CO LTD +1

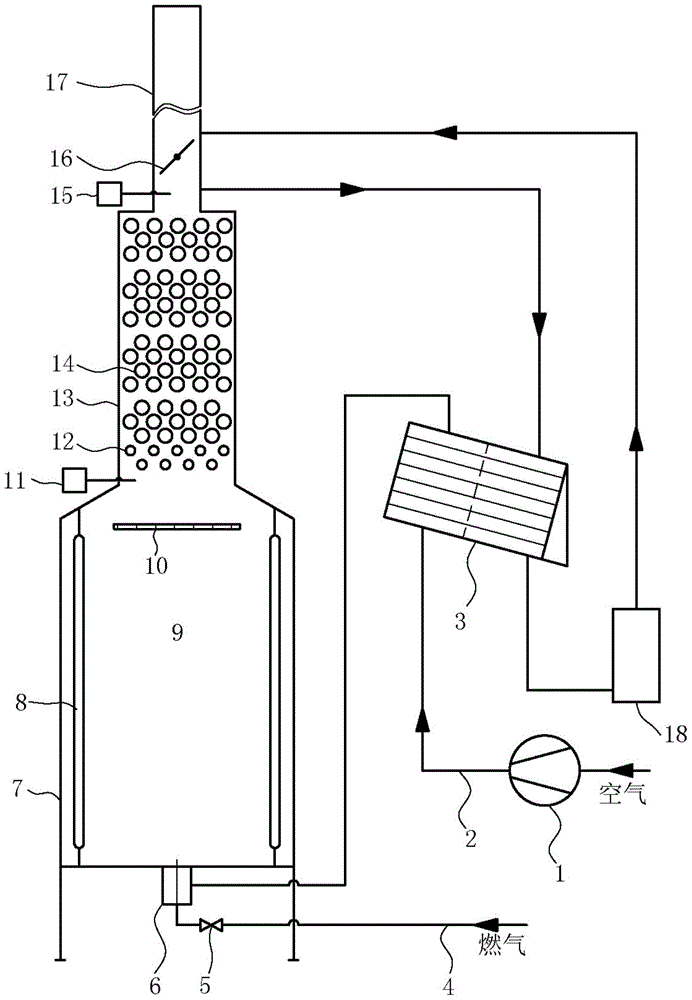

A once-through diffuse combustion tubular heating furnace system and burner

ActiveCN104696965BSuppress generationReduce the intensity of the combustion reactionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberHearth

The invention relates to a straight-flow type dispersion combustion tubular heating furnace system and a combustor. Fuel gas and preheated air are injected into a combustion chamber of a radiation chamber by a high-speed fuel gas combustor; the temperature of a hearth is higher than spontaneous ignition temperature; the injection speed is greater than the flame spreading speed during combustion of the fuel gas, so that visible luminous flame cannot be formed; reaction of combustion is performed in the whole radiation chamber; heat distributed in the radiation chamber is uniform; the maximum temperature of a combustion process is smaller than 1700K; and NOx is restrained effectively. A reflecting plate is arranged on a downstream portion of the radiation chamber, the circumstance that the fuel gas and the hot air are in a short-circuiting state in the radiation chamber and directly enter a convection chamber can be avoided, backflow is formed on a downstream portion of the reflecting plate, standing time of smoke in the convection chamber is prolonged, and combustible ingredients such as CO can be sufficiently burnt out. The straight-flow type dispersion combustion tubular heating furnace system has the advantages of high combustion efficiency, ultra-low pollutant emission, uniform temperature field and the like. Moreover, the straight-flow type dispersion combustion tubular heating furnace system is suitable for building a new tubular heating furnace or modifying an old tubular heating furnace.

Owner:EAST CHINA UNIV OF SCI & TECH

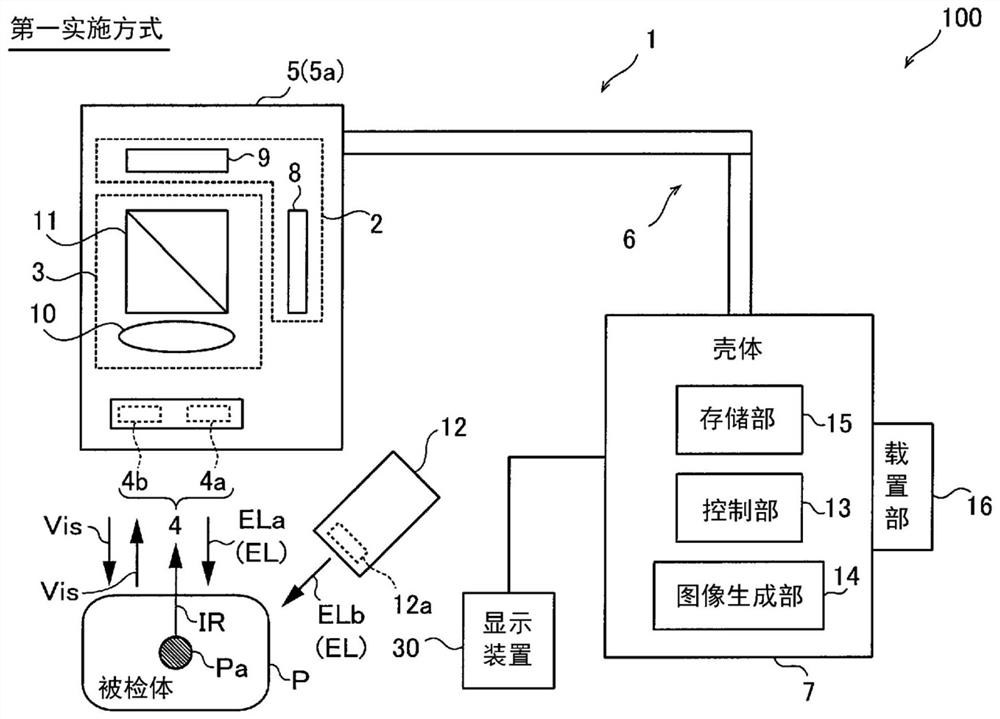

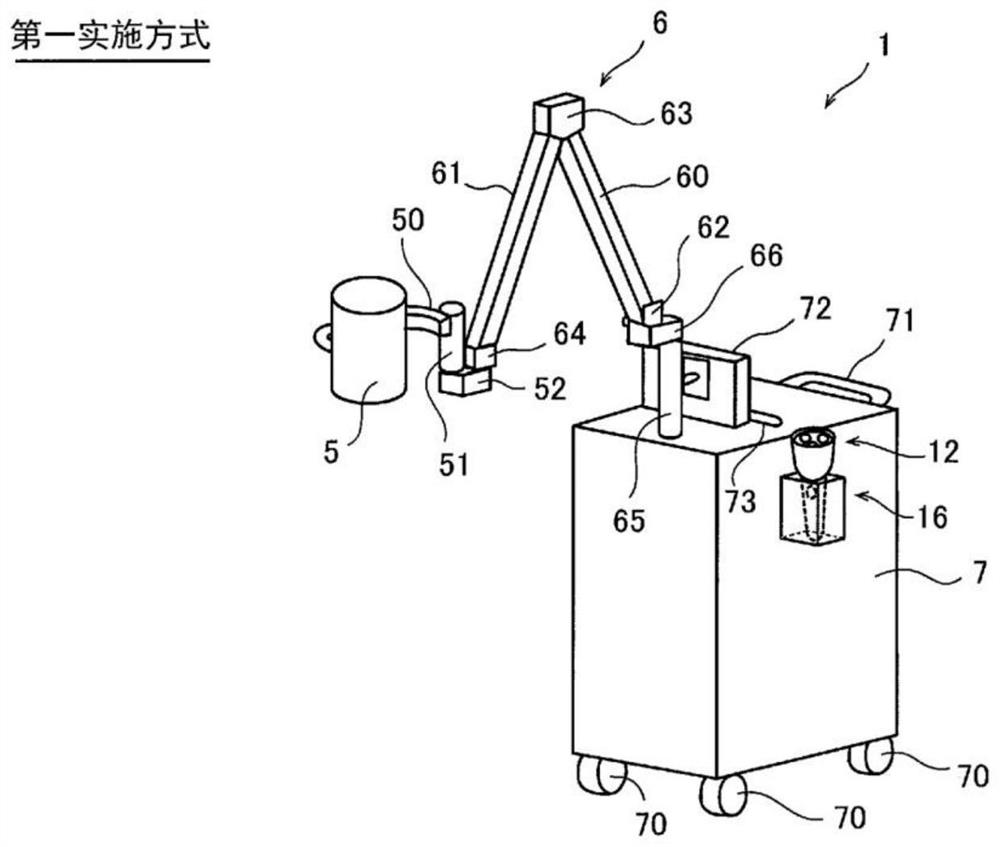

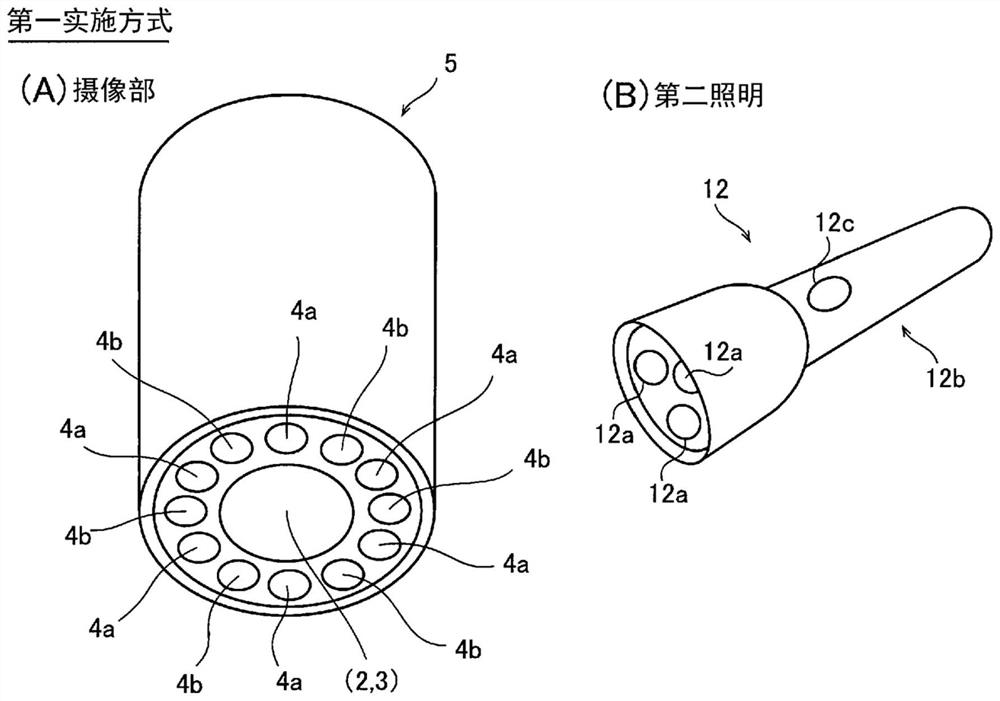

Treatment support device

InactiveCN112153942AHigh strengthGuaranteed exposure rangeSurgeryVaccination/ovulation diagnosticsMedicineFluorescence

A treatment support device (1) comprises: a first light (4) that radiates excitation light (EL) for a fluorescence agent (Pa) at a subject (P); an imaging unit (5) that includes a detection unit (2) that detects fluorescence (IR) that is emitted from the fluorescence agent (Pa) as a result of the radiated excitation light (EL); a portable second light (12) that radiates excitation light (EL) for the fluorescence agent (Pa) at the subject (P); and an image generation unit (14).

Owner:SHIMADZU SEISAKUSHO CO LTD

Electric connection box

InactiveCN101188351BSuppress high temperatureCooling/ventilation/heating modificationsElectrical connectionHemt circuits

Owner:AUTONETWORKS TECH LTD +2

A low-nitrogen combustion system for a regenerative heating furnace and its working method

ActiveCN113154380BThe flow is easy to adjustRaise the theoretical combustion temperatureGaseous fuel burnerCombustion systemFlue gas

A low-nitrogen combustion system for a regenerative heating furnace, including a furnace and burners A and B on both sides of the furnace, and also includes an ignition system, an air supply system, a flue gas circulation system and a gas supply system; the ignition system includes Air induction device and ignition pipe; said air supply system includes air induction device, air supply pipe and the air regenerator on the top of burner A and burner B; said flue gas circulation system includes induced draft fan, flue gas pipe and The flue gas regenerator on the upper part of nozzle A and burner B, two flue gas pipes are connected between the two flue gas regenerators, and an induced draft fan is connected between the two flue gas pipes; the gas supply system includes four Level gas pipelines are respectively the first low-pressure gas pipeline, high-pressure gas pipeline, second low-pressure gas pipeline and medium-pressure gas pipeline, which are connected to the injection port inside the burner and the furnace in layers. It can effectively suppress the local high temperature of the flame caused by concentrated heating, let the combustion temperature of the burner release in layers, and further avoid the local high temperature of the flame.

Owner:SHANDONG YIRAN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com