Electric connection box

A technology for electrical connection boxes and circuit substrates, used in electrical components, cooling/ventilation/heating transformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be specifically described below with reference to the drawings.

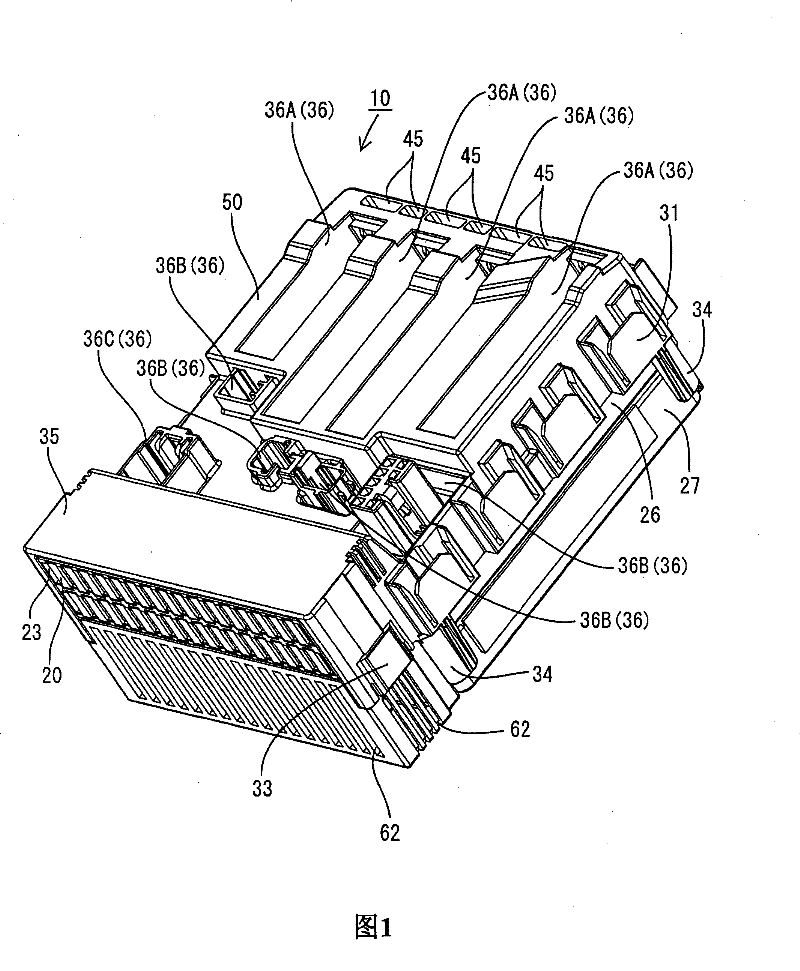

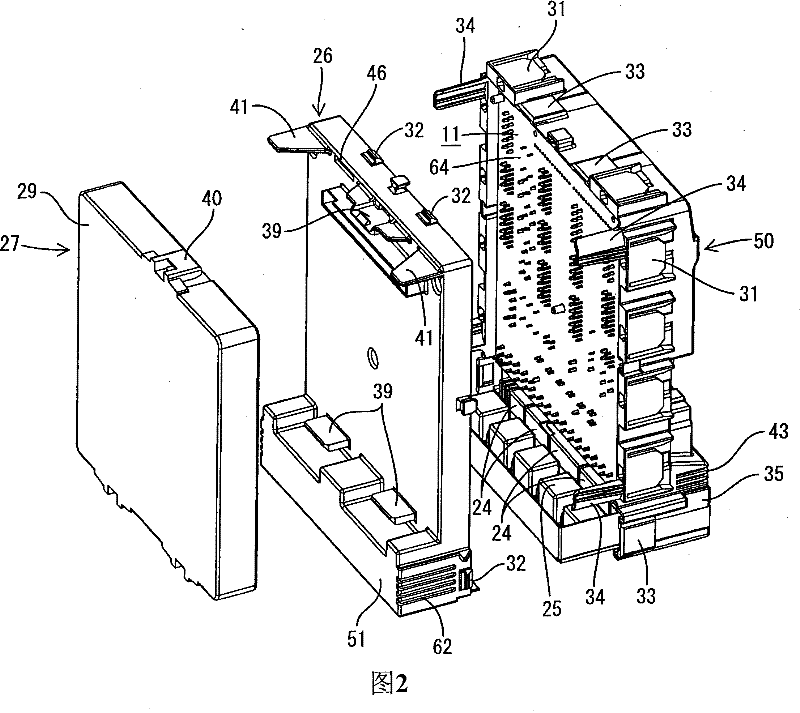

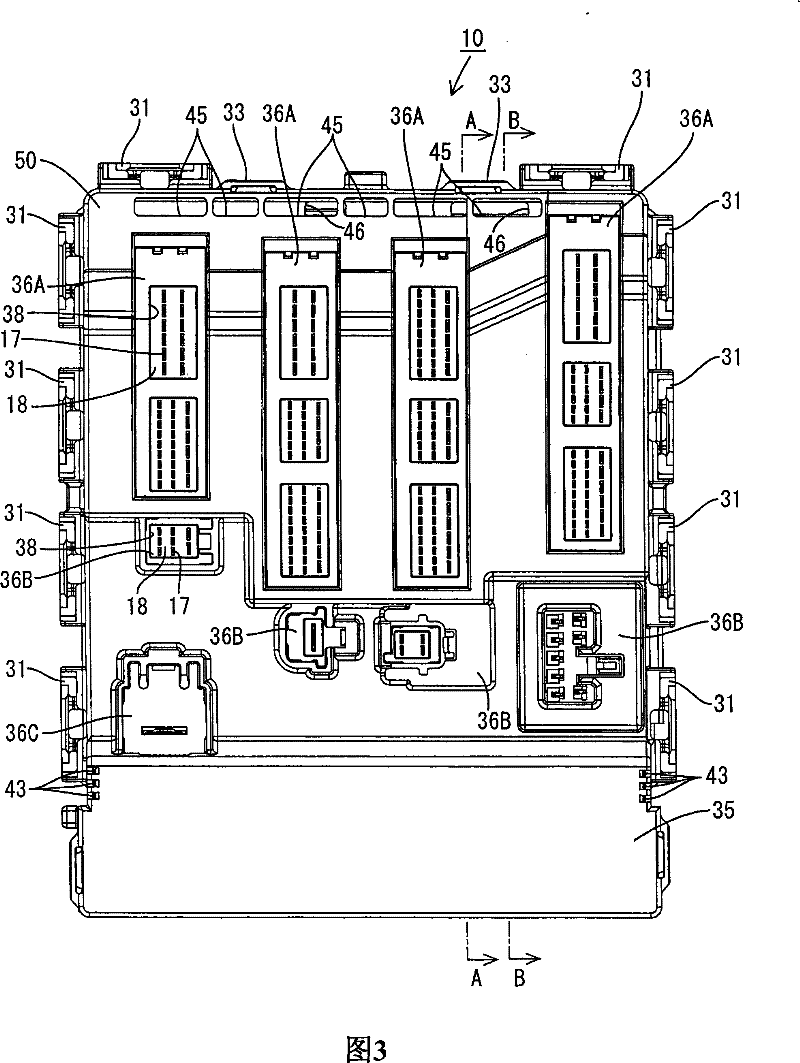

[0035] refer to Figure 1 to Figure 7 The first embodiment of the present invention will be described. The electrical junction box of this embodiment is installed between a battery (not shown) and vehicle electrical components (not shown) such as lamps and power windows, and controls the energization and de-energization of these vehicle electrical components. The electrical connection box is as Image 6 The shown vertical state is installed in the interior of a car (not shown) and used. In this electrical connection box, a circuit board 11 is accommodated in a flat case 10 .

[0036] (circuit board)

[0037] The circuit board 11 is substantially rectangular, and conductive paths (not shown) are formed on both sides thereof by printed wiring technology. In the circuit substrate 11, in Figure 7 On the surface on the middle right side (hereinafter referred to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com