A once-through diffuse combustion tubular heating furnace system and burner

A tubular heating furnace and dispersion combustion technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of limited potential and inapplicability of tubular heating furnaces, achieve simple structure, suppress the formation of NOx, The effect of reducing the intensity of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

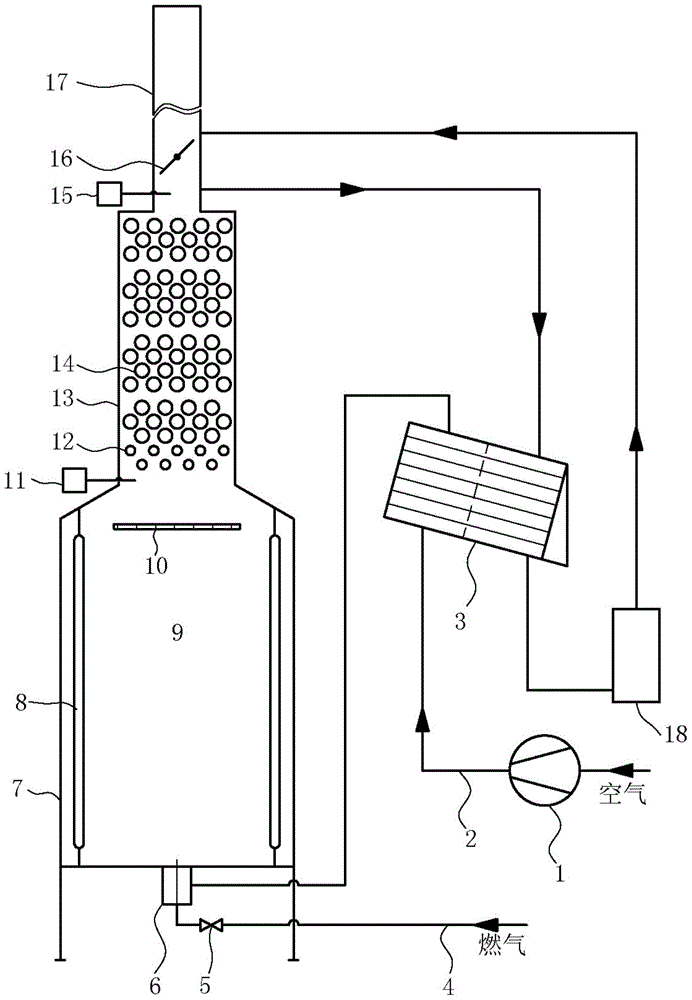

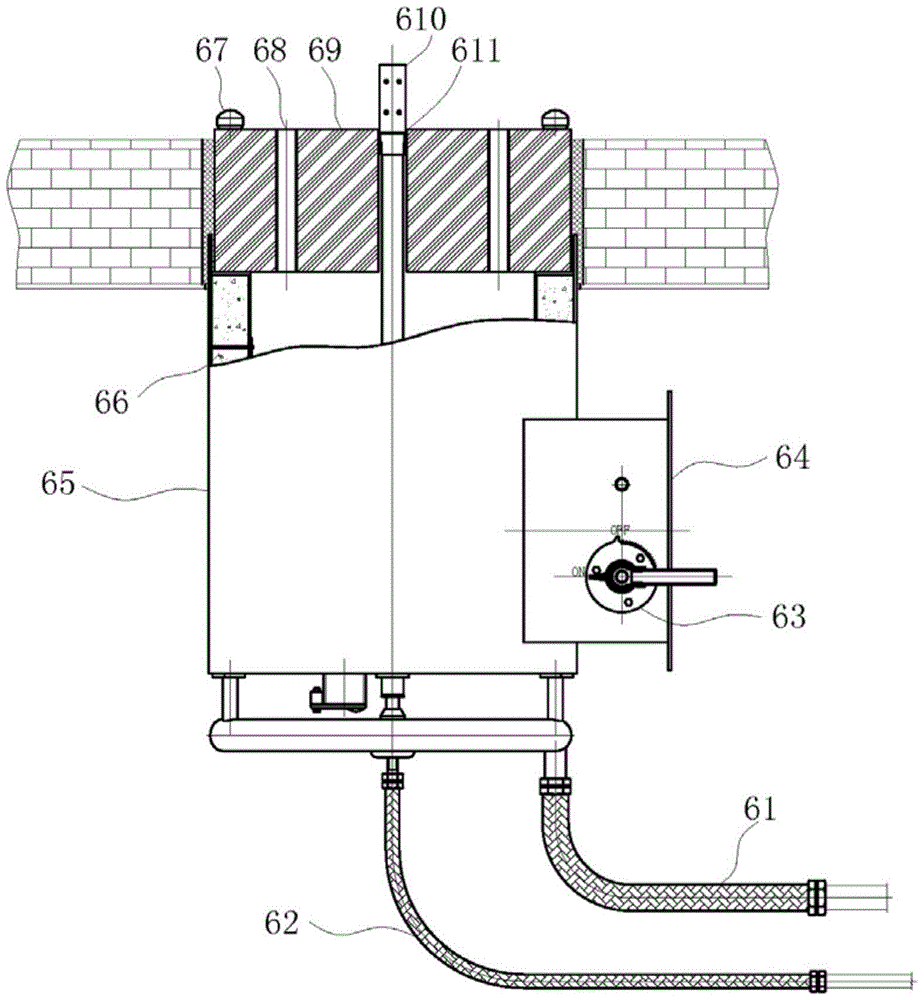

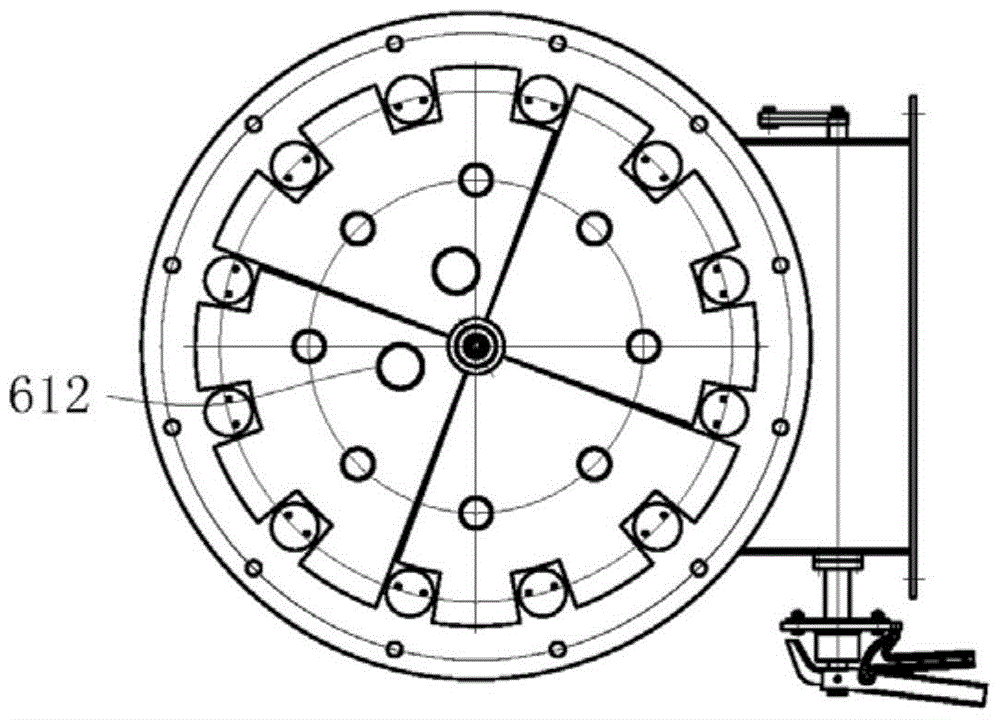

[0040] A direct-flow diffuse combustion tubular heating furnace. The cold air from the blower is heated by the air preheater and then injected into the radiation chamber through the burner. The gas from the gas pipe network is injected into the radiation chamber through the burner. The temperature of the radiation chamber is high. Due to the self-ignition temperature of the gas, hot air and gas entrain the combustion products in the radiation chamber, forming a strong backflow in the radiation chamber, and the jet velocity of the reactants is greater than the flame propagation speed of the gas combustion, so no visible luminous flame can be formed in the radiation chamber. The combustion of gas fills the entire radiant chamber, and the maximum temperature of the combustion process is less than 1700K, which effectively suppresses the formation of NOx; the reflector prevents the high-speed gas and hot air from forming a short circuit in the radiant chamber and directly enters the ...

Embodiment 2

[0049] The tubular heating furnace system and burner structure of Embodiment 2 are consistent with Embodiment 1. With methane as the fuel gas, the excess air coefficient is 1.10, and the velocity field, temperature field and CO and NOx emissions of the diffuse combustion in the combustion chamber 9 of the 37.8MW tubular heating furnace are simulated and studied. The diameter of the combustion chamber 9 is 5400mm, and the height is 10000mm, the volume heat intensity of combustion chamber 9 is 165kW / m 3 , the speed at which methane is ejected from the gas gun 67 is 60m / s, the cold air is heated to 673K by the air preheater 3, the speed at which the hot air is ejected from the air hole 68 is 120m / s, and the diameter of the reflecting plate 10 is 3430mm, It is 0.64 times of the diameter of the combustion chamber. With reference to the operating conditions of general refining and chemical tubular heating furnaces, the temperature of the wall surface of the combustion chamber 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com