Anti-explosion tank

An explosion-proof tank and inner cylinder technology, applied in the direction of container, packaging, transportation and packaging, can solve the problems of the explosion-proof tank being bulky, reducing the weight of the tank, unable to suppress high temperature and flame, etc. Flame, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

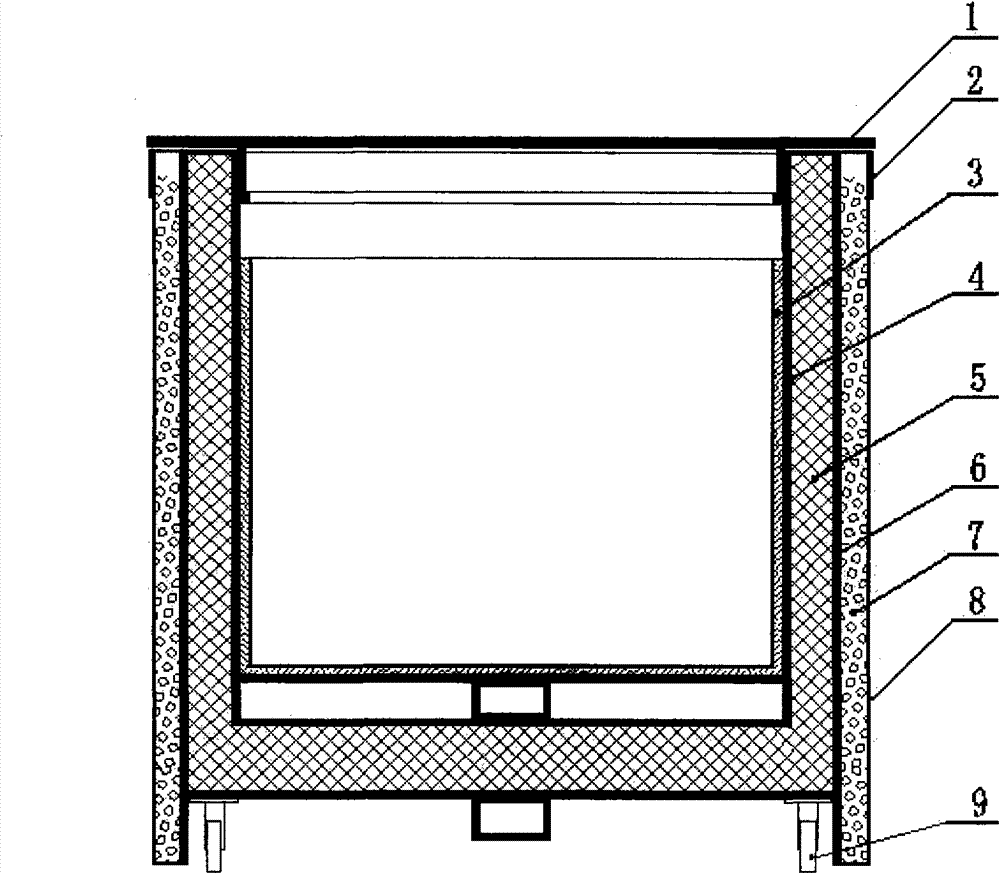

[0016] The specific embodiment of the present invention is described below in conjunction with accompanying drawing, figure 1 It is a schematic diagram of the overall structure of a preferred embodiment of an explosion-proof tank of the present invention.

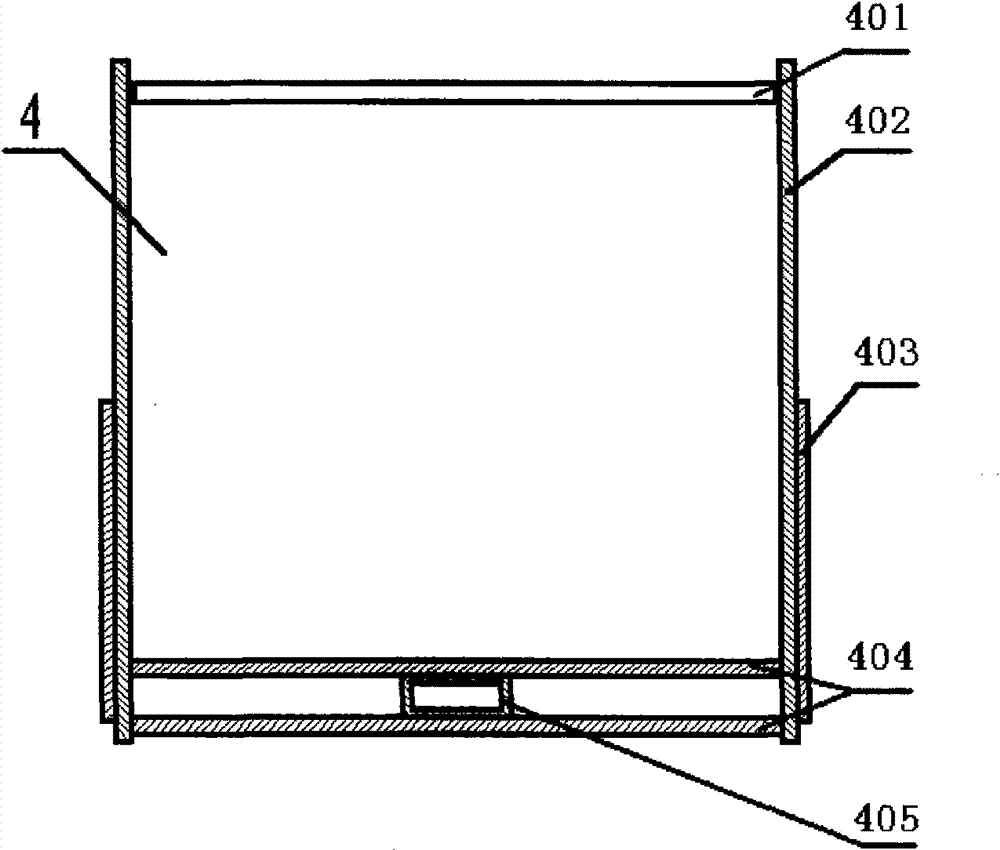

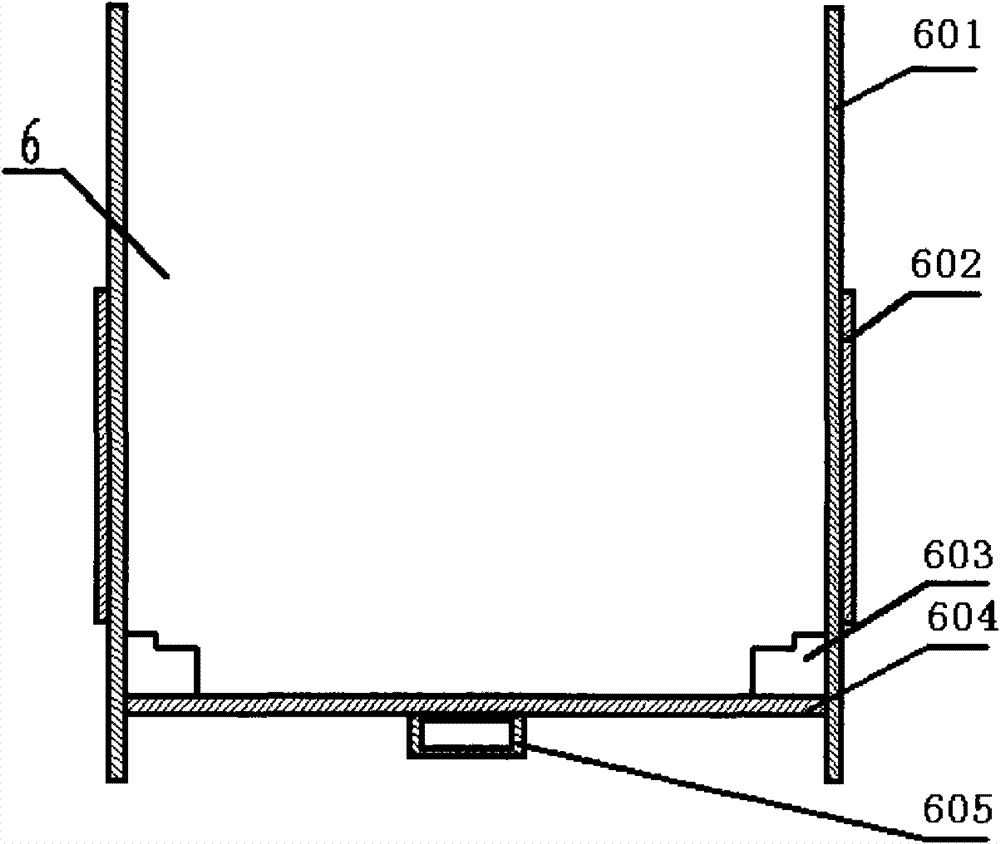

[0017] refer to figure 1 Schematic diagram of the structure of an explosion-proof tank, which consists of a top cover 1, a sealing ring 2, a fire extinguishing lining 3, an inner cylinder 4, a buffer layer 5, an outer cylinder 6, a foam material layer 7, an outer shell 8 and casters 9. The inner cylinder 4 constitutes the inner protective cylinder layer, and the outer cylinder 6 constitutes the outer protective cylinder layer. Between the outer cylinder 6 and the inner cylinder 4 is a buffer layer 5, the buffer layer 5 is made of a filled polymer energy-absorbing material, and the energy-absorbing material is added with expanded granular materials (such as vermiculite, etc.) before the polyester material is molded and soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com