Method for retreading tires

A tire retreading and carcass technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of restricting the scale development of cold retreading industry and overloading tires, and achieve small crown deformation, long service life, and anti-aging performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

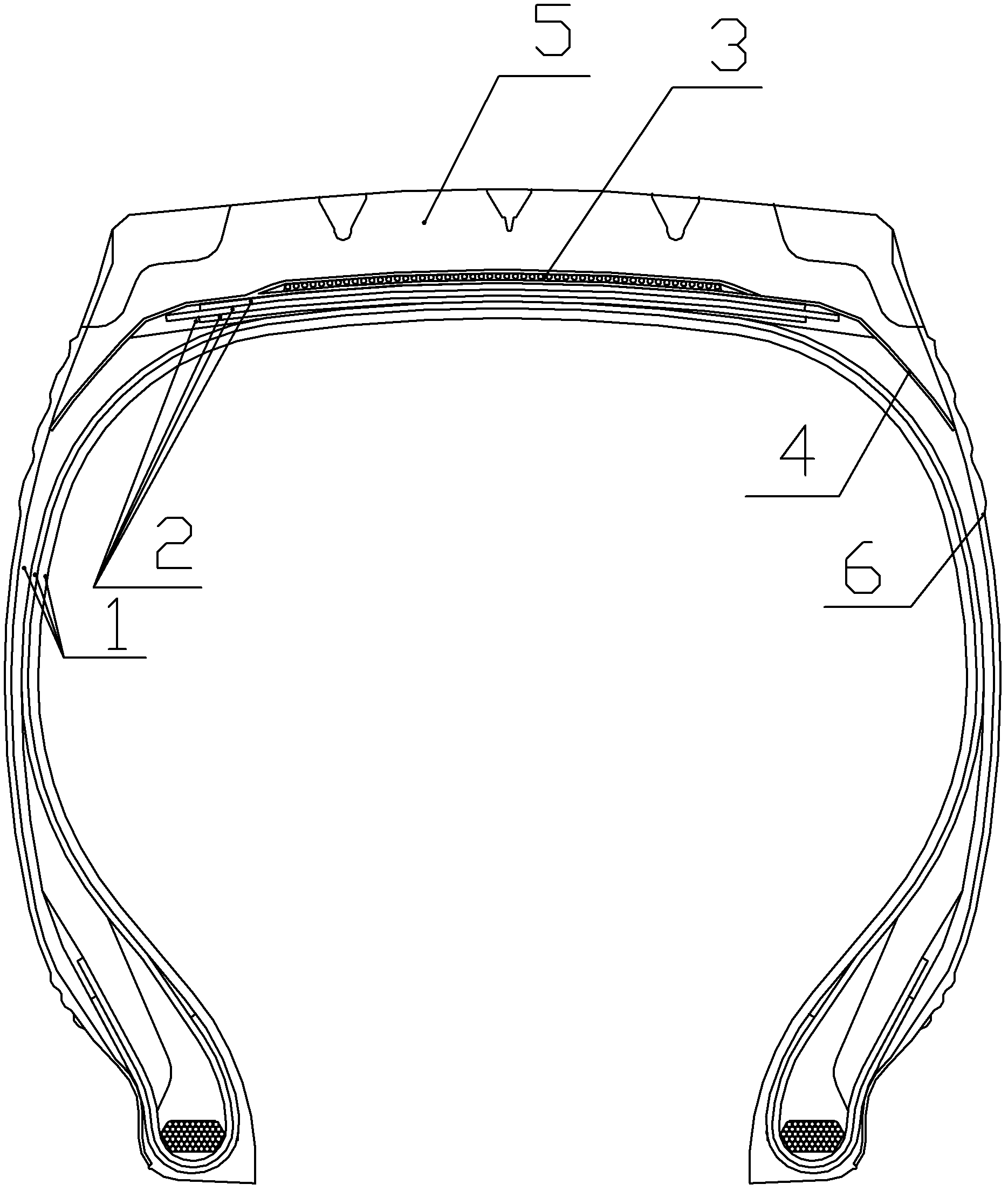

[0024] combine figure 1 , a method for tire retreading, comprising the steps of:

[0025] Step 1. Select waste tires of the same specification as raw tires, divide each raw tire to obtain carcass and belt layers, select those relatively complete carcass and belt layers, and grind them for later use.

[0026] Step 2. After recombining the carcass 1 and the belt layer 2 selected in step 1 one-to-one to form the green tire, set the steel wire explosion-proof layer 3, the middle cushion rubber 4 and the tire crown on the belt layer of the green tire rubber 5, and the sidewall rubber 6 is set on the carcass, and then vulcanized to obtain a retreaded tire.

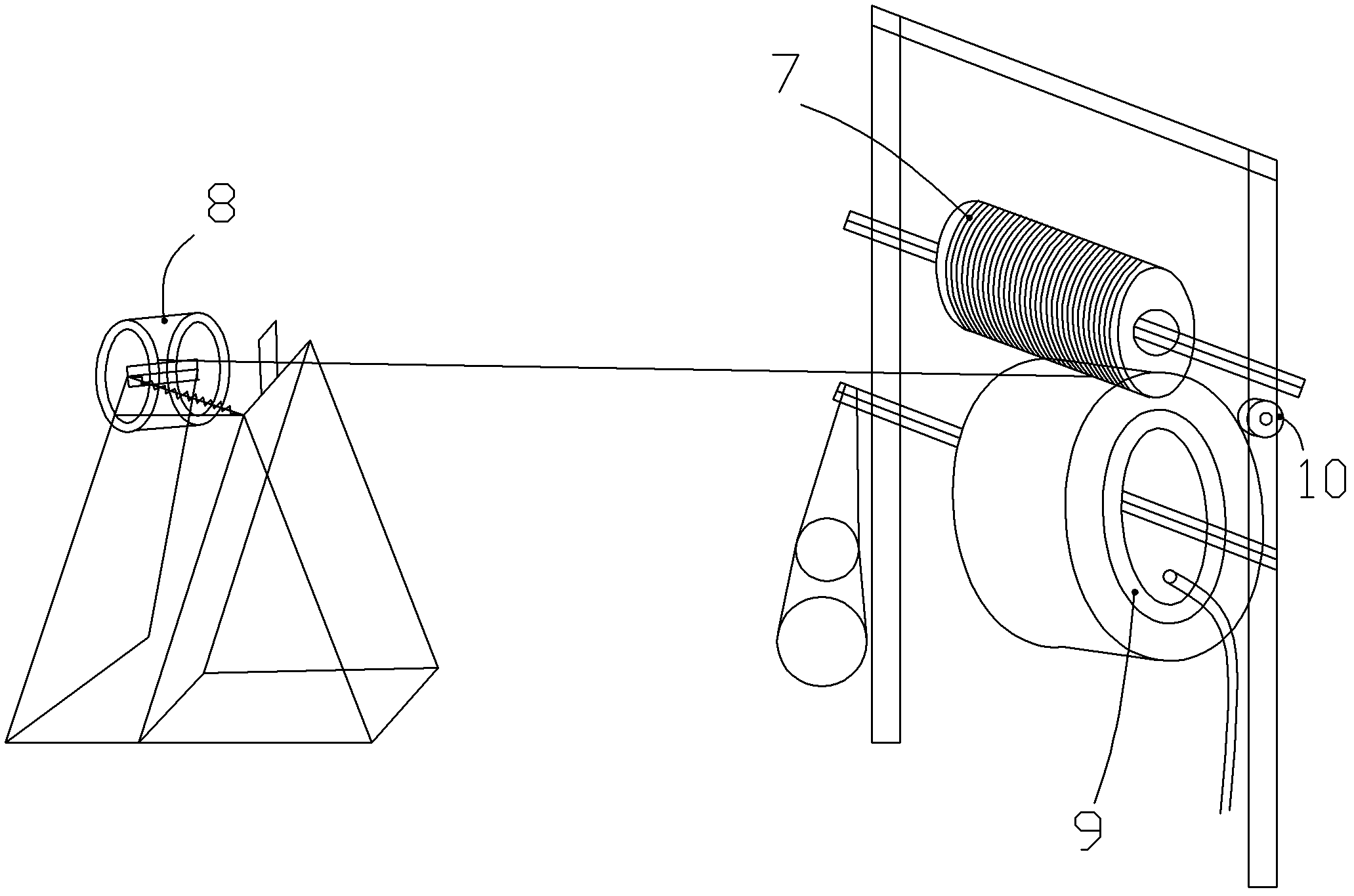

[0027] The above-mentioned steel wire explosion-proof layer is realized in this way. A single steel wire curtain wiring is selected, and the leading wire head of the steel wire curtain wiring is first fixed on one side of the upper layer of the belt layer with a film, and then on the upper layer of the belt layer along the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com