Non-friction air-compression and power generator

A generation device, frictionless technology, applied in the direction of variable displacement engine, reciprocating piston engine, machine/engine, etc., can solve the problems of material intolerance, oil and gas leakage, material wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed descriptions of several preferred embodiments with reference to the drawings.

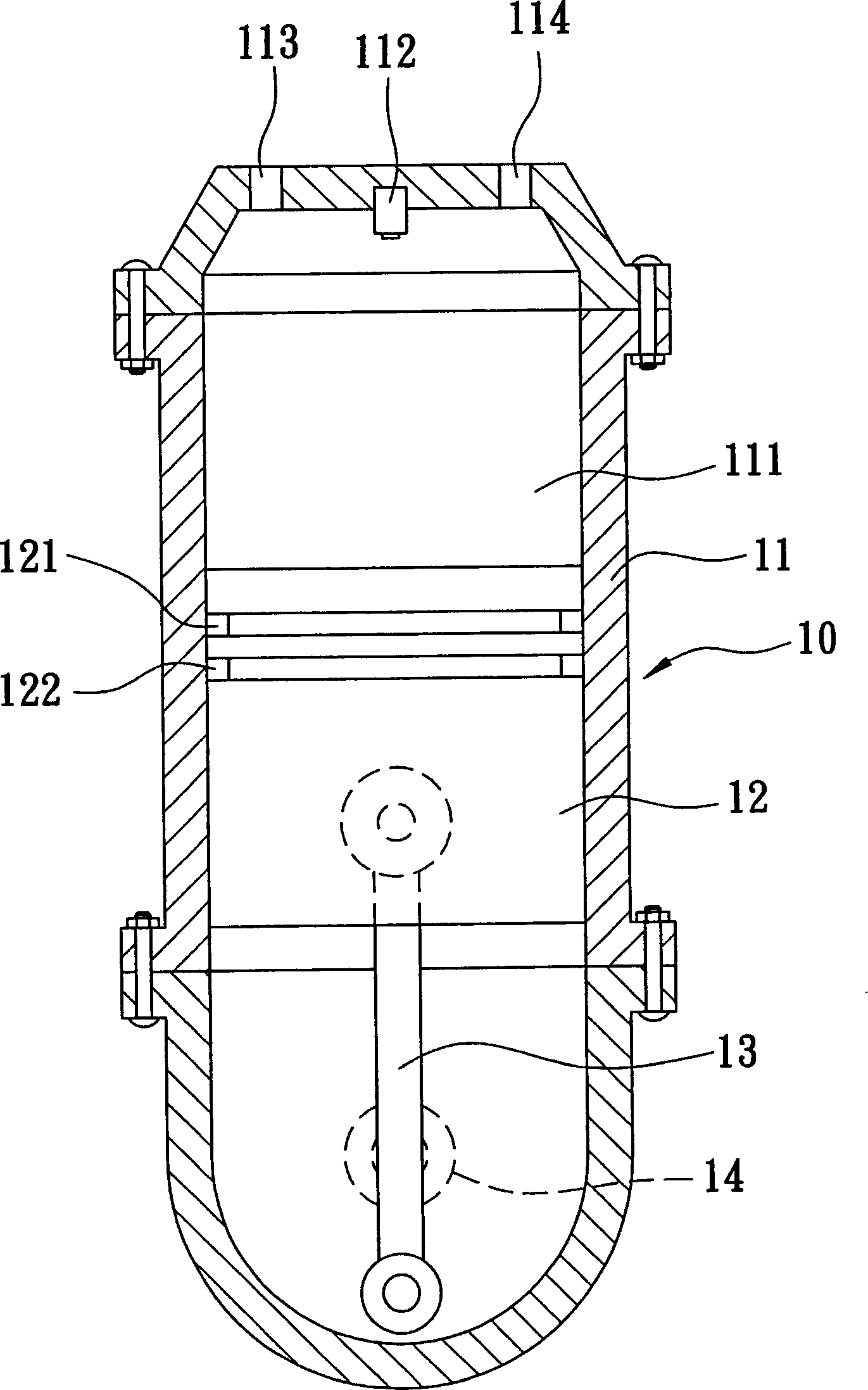

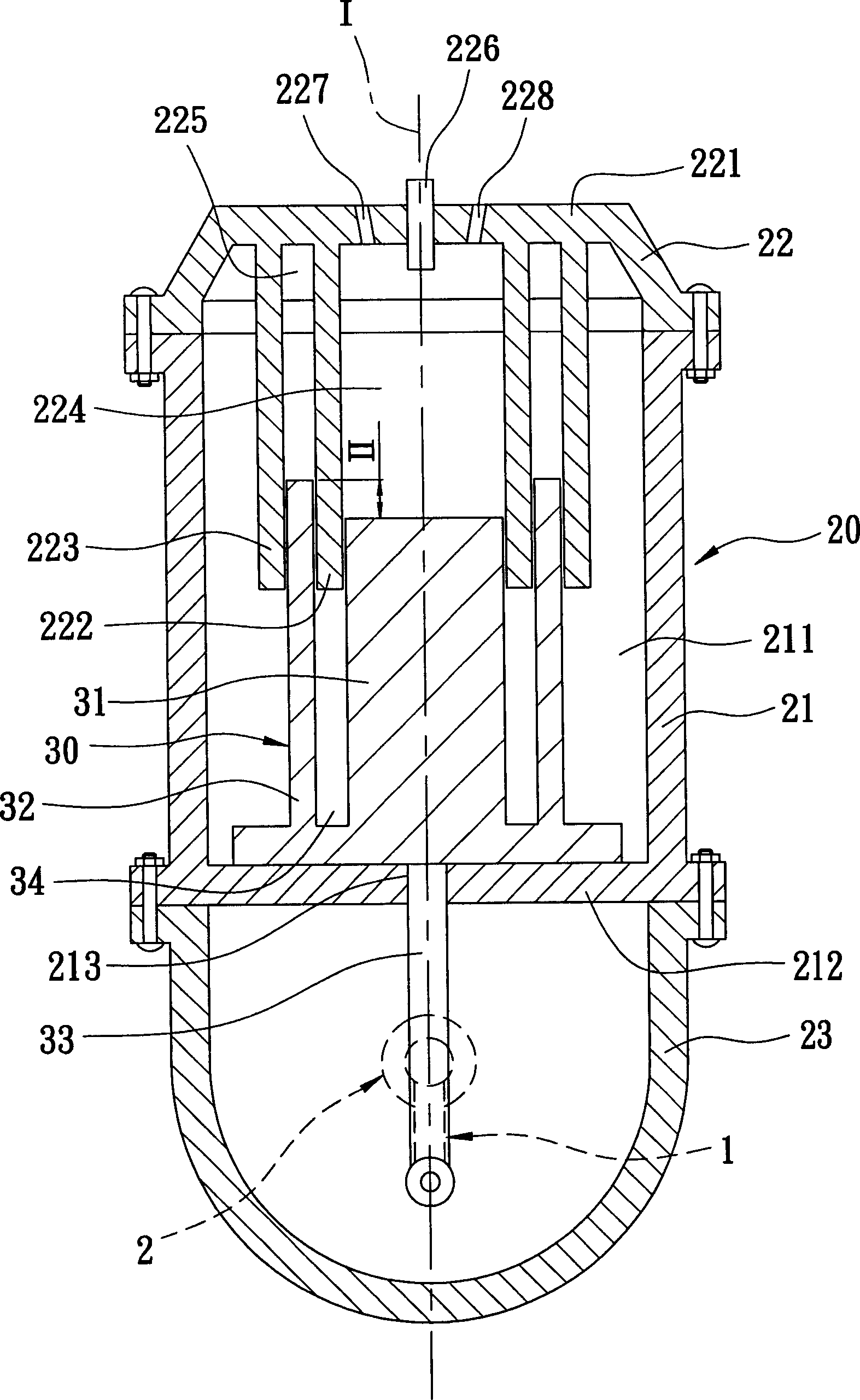

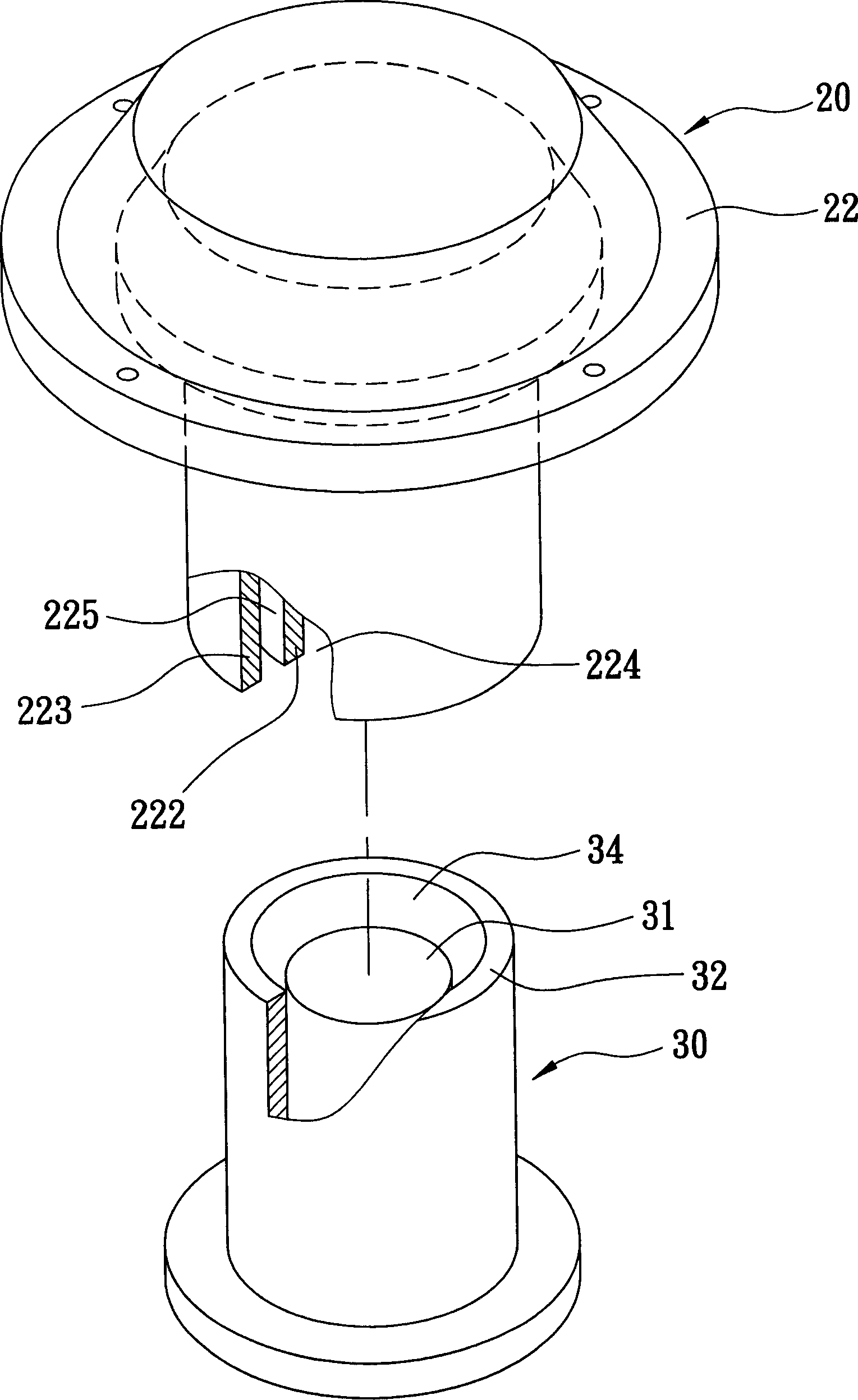

[0021] see figure 2 , image 3 As shown, in the first preferred embodiment of the frictionless power generating device of the present invention, it mainly includes a body unit 20, a piston unit 30, a crank unit 1 and a main shaft 2, and then, the above-mentioned each unit The shape and combined space type are described in detail later.

[0022] The body unit 20 mainly has a cylinder body 21, an upper cover body 22 bolted and fixed above the cylinder body 21, and a shaft seat body 23 bolted and fixed below the cylinder body 21, the cylinder body 21 is hollow inside A chamber 211 is formed, the bottom of which has a closed bottom plate 212, the bottom plate 212 is provided with a sliding hole 213 in the center, the upper cover body 22 is formed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com