Low-nitrogen double-heat-storage natural gas burner

A dual heat storage and natural gas technology, applied in heat storage equipment, gas fuel burners, burners, etc., can solve the problem that the sensible heat of high-temperature flue gas cannot be effectively recycled, the fire power cannot be adjusted to become smaller, and the fire power adjustment is single, etc. problems, to achieve the effect of avoiding local high temperature of the flame, significant energy saving, and suppression of local high temperature of the flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

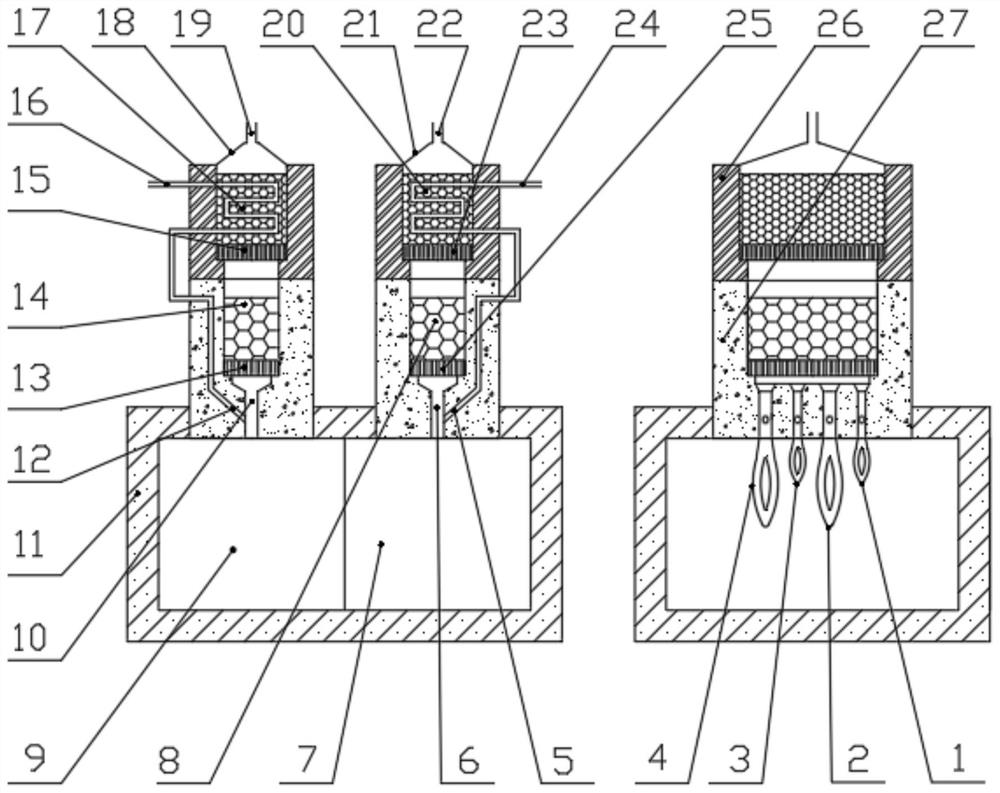

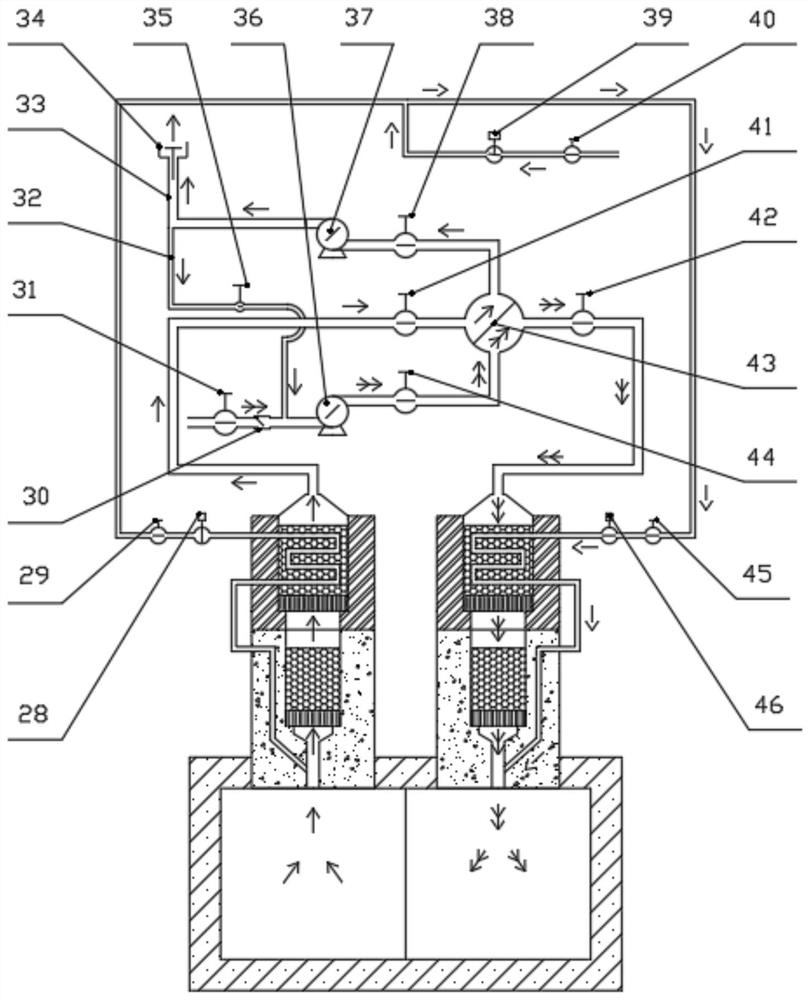

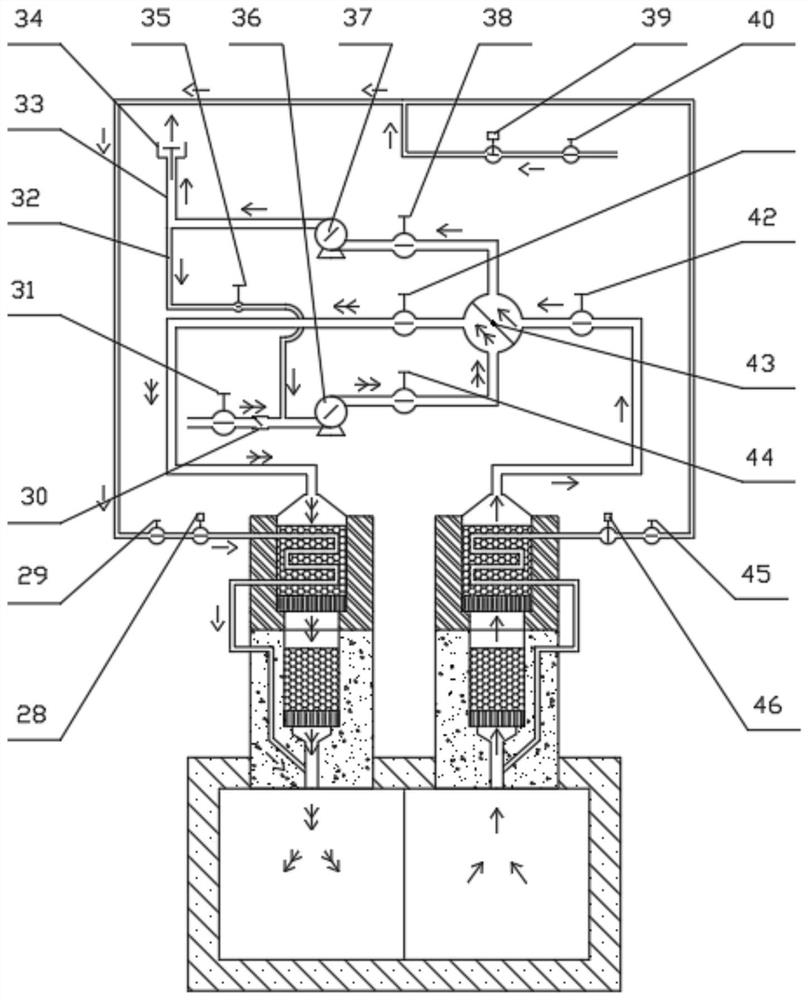

[0030] Such as Figure 1-3 As shown, the embodiment of the present invention provides a low nitrogen double regenerative natural gas burner, including a double accumulator multi-blade burner and a combustion-supporting mixed air and gas control system. It is characterized in that the double accumulator multi-blade burner includes a furnace body 11. Furnace body 11 is divided into furnace B zone 7 and furnace A zone 9. Two high-temperature regenerators 27 are arranged symmetrically on the top of furnace body 11, and the two high-temperature regenerators 27 are connected to furnace B zone 7 and furnace A respectively. Zone 9 is connected, and the tops of the two high-temperature regenerators 27 are fixedly connected with medium-temperature regenerators 26;

[0031] The high-temperature regenerator 27 at the top of the furnace B area 7 is provided with a burner B high-temperature regenerator regenerator 8, and the bottom of the burner B high-temperature regenerator regenerator 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com