Ternary composite system suitable for high-temperature and high-salinity oil reservoir, and preparation method thereof

A ternary system, high salinity technology, applied in the direction of chemical instruments and methods, drilling compositions, mining fluids, etc., can solve the problem of polymer solution viscosity reduction, so as to enhance the viscosity-increasing ability and improve recovery The effect of increasing the rate and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1. Preparation of polymers suitable for high temperature and high salinity reservoirs

[0028] (1) Dissolve 108g of benzyl alcohol in 200mL of ethanol to form an ethanol solution of benzyl alcohol, then add 70g of paraformaldehyde, lye made of 106g of sodium carbonate and 290mL of water, stir well and heat to 95-100°C for closed reaction 5-6 hours. After cooling, the reactant was poured into 500 mL of cold water, and the crude product was precipitated. The crude product was recrystallized from absolute ethanol to obtain 121 g of white crystalline compound II—tribenzyl alcohol, with a yield of 72%.

[0029] The synthetic route is as follows such as formula (1), and paraformaldehyde is depolymerized to obtain formaldehyde monomer at this reaction temperature, so the reactant in formula (1) is formaldehyde monomer:

[0030]

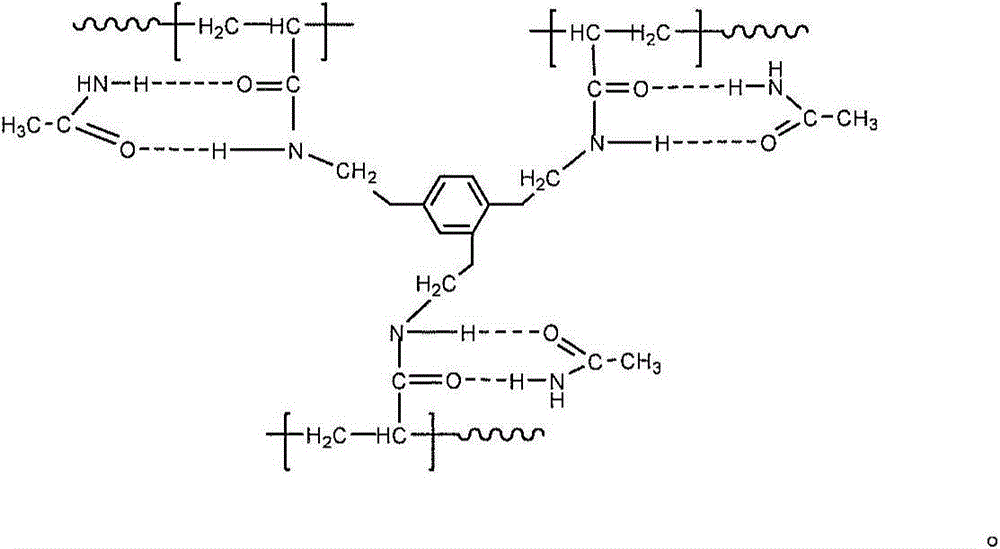

[0031] (2) Stir 10g of partially hydrolyzed polyacrylamide (HPAM) (degree of hydrolysis 25-30mol%) and 500mL of water evenly, heat to 40...

Embodiment 2

[0037] Example 2. Preparation of ternary composite system suitable for high temperature and high salinity reservoirs

[0038] Add 0.025-0.3wt% alkylbenzene sulfonate surfactant and 0.4-1.2wt% sodium carbonate in each polymer DQHTP solution of 1700mg / L-3700mg / L that embodiment one obtains, at 25 ℃ condition Stirring for 30 minutes, a series of ASP flooding systems suitable for high-temperature and high-salinity reservoirs with a viscosity of 2-30mPa·s were obtained, as shown in 1 in Table 1. # -5 # .

Embodiment 3

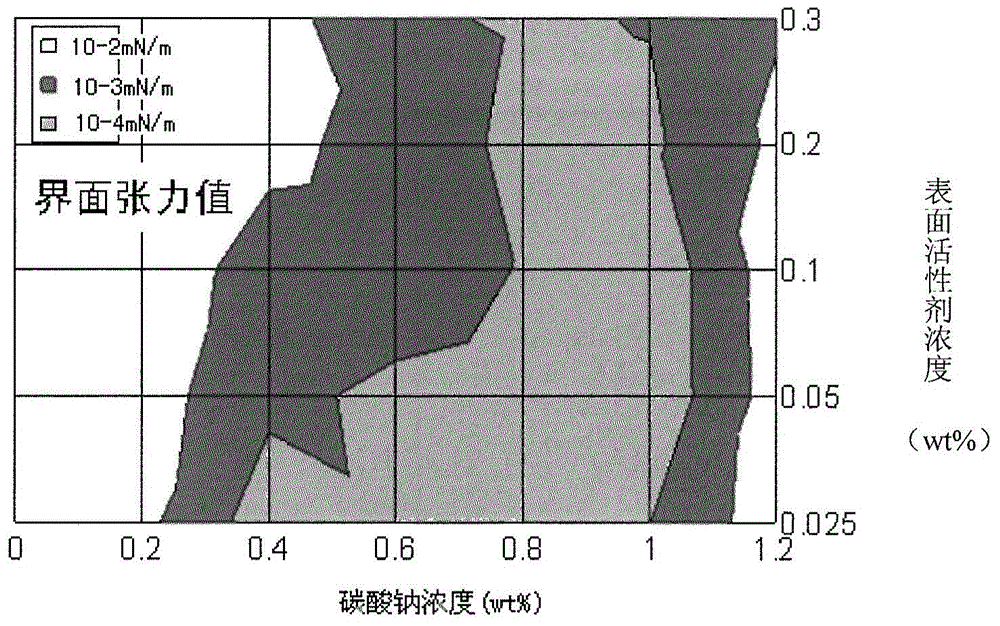

[0039]Embodiment three, the influence of ternary composite system of the present invention on oil-water interfacial tension

[0040] With alkylbenzene sulfonate (concentration is 0.025wt%-0.3wt%), sodium carbonate (concentration is 0.4wt%-1.0wt%) and the polymer that embodiment one obtains (concentration is 3200mg / L) preparation obtains a The series is suitable for the ternary compound system of high temperature and high salinity reservoirs.

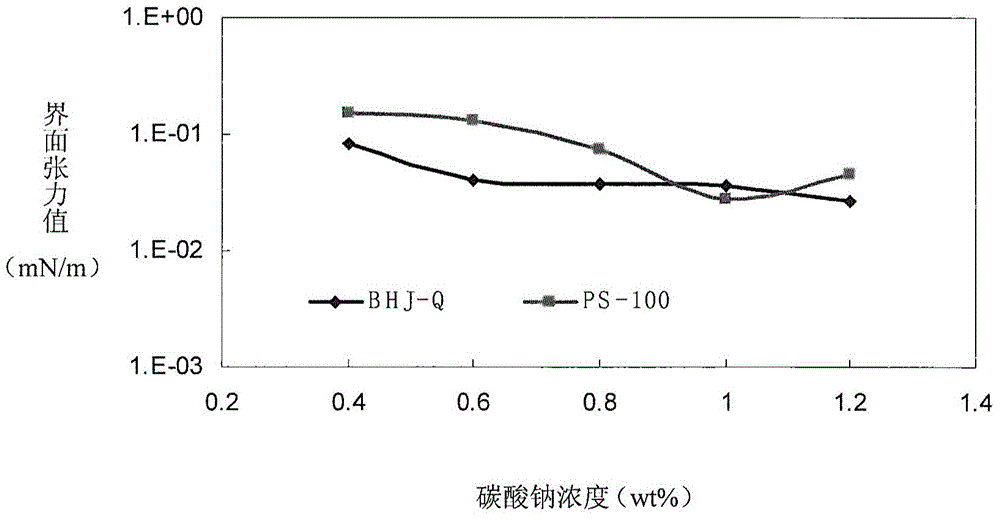

[0041] Take existing two kinds of ternary composite systems as comparative example: one is made of petroleum sulfonate product PS-100 (concentration is 0.3wt%), sodium carbonate (concentration is 0.4-1.2wt%) and partially hydrolyzed polyacrylamide (concentration is 3200mg / L, degree of hydrolysis 25mol%) is prepared; Another is by heavy alkylbenzene sulfonate BHJ-Q (concentration is 0.3wt%), sodium carbonate (concentration is 0.4-1.2wt%) and part It is prepared by hydrolyzing polyacrylamide (concentration: 3200mg / L, degree of hydrolysis:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com