Panel for modular housing construction in particular of ventilating and air conditioning plants

A kind of air conditioning equipment, modular technology, applied in the direction of building components, building construction, heating and ventilation hood/cover, etc., can solve the problem of high heat conduction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

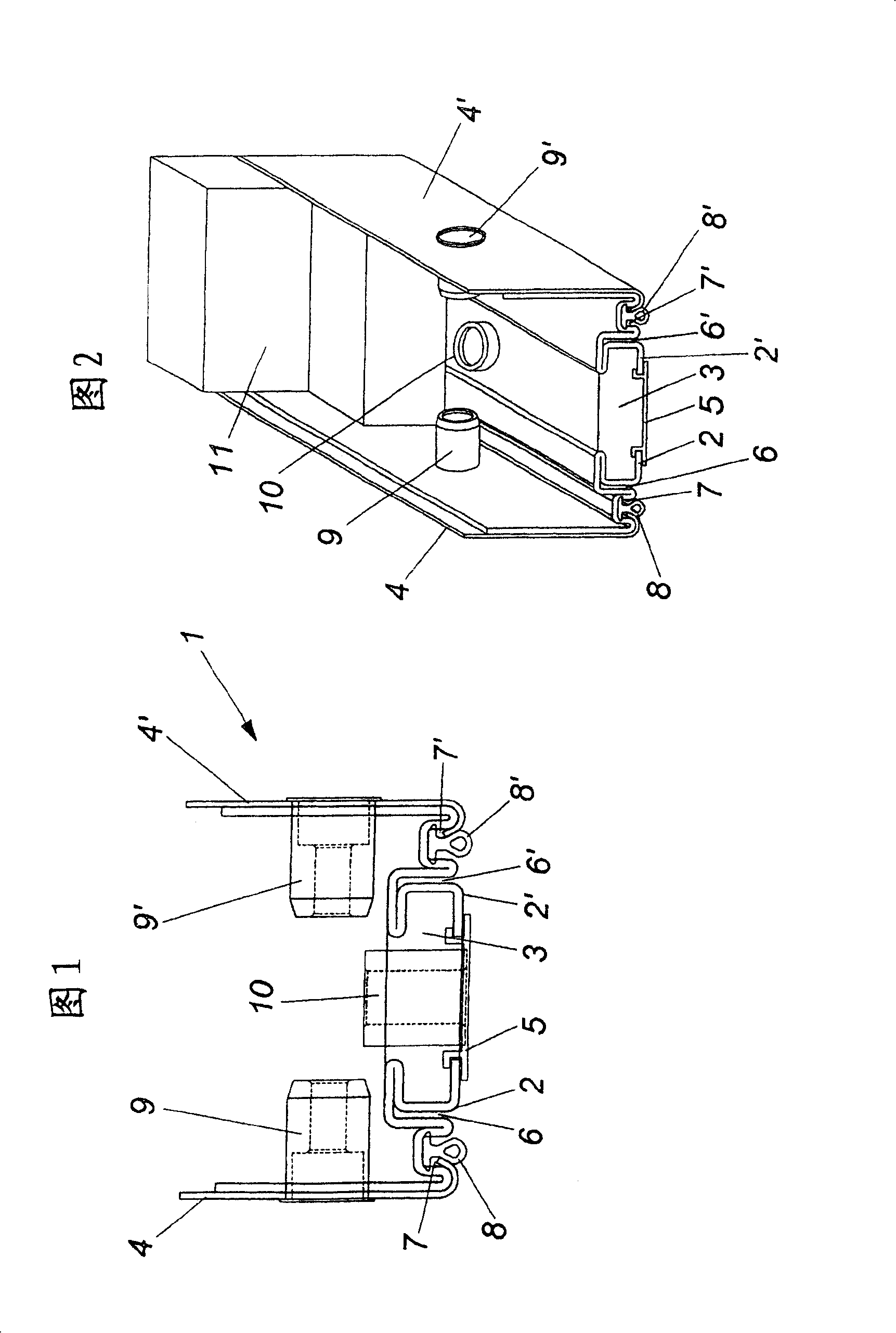

[0021] Figure 1 shows a cross section through the end face of a panel. This end face has two metal profiles 2 , 2 ′ at a distance from one another, between which a heat insulating material 3 is arranged. A metal connection is provided between the metal profiles 2, 2', which leads to an undesired thermal connection of the side wall 4 to the opposite parallel side wall 4'. The metal material 2 , 2 ′ surrounds the substantially cuboid thermal insulation material 3 at the narrow sides of the thermal insulation material, wherein the metal profile 2 , 2 ′ surrounds the edge of the thermal insulation material 3 with a substantially U-shaped edge. The heat insulating material 3 is, for example, PU resin, which is cast in liquid state between the metal profiles 2, 2' during manufacture. In order to prevent liquid resin from flowing out, a cover (Keder) 5 is provided. This plastic cover is removed again after the heat insulating material 3 has hardened.

[0022] The metal profiles 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com