Ultrasonic-assisted pulp electrolysis method for tailing sand

A pulp electrolysis and ultrasonic technology, which is applied in the direction of photographic auxiliary process, photographic process, instrument, etc., can solve the problems of low metal recovery rate, poor sorting effect and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

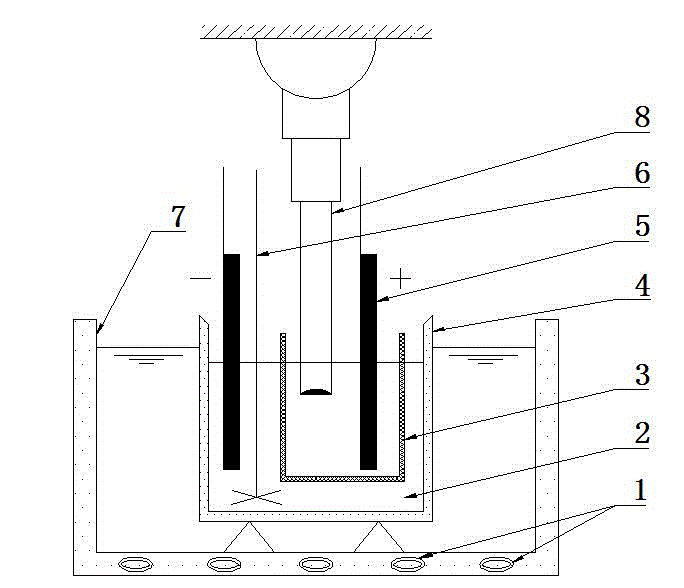

Image

Examples

example 1

[0025] Example 1. Take 500g of copper-bearing tailings from Chenzhou Nonferrous Garden, Hunan Province. The minerals contained in the copper-bearing tailings mainly include chalcopyrite, pyrite, chalcocite, arsenic tetrahedrite, etc., and the particle size is less than 300 mesh. The process conditions of the pulp electrolysis are: the electrolyte of the pulp is HCl+NaCl system, the liquid-solid ratio is 10:1, the anode is a ruthenium-plated titanium mesh, the cathode is a stainless steel plate, the pole distance between the electrodes is 5cm, PH=1, and the chloride ion concentration is : 200g / L, electrolysis temperature is 65℃, cathode current density is 160A / m 2 , The electrolysis time of each batch of mineral powder is 2 hours, and the ultrasonic power is 50W.

[0026] The main electrochemical reaction in the process of ultrasonic assisted pulp electrolysis is.

[0027] 2CuFeS 2 +3 / 2O 2 +4H + =2Cu + +2FeOOH+4S 0 +H 2 O.

[0028] CuFeS 2 +3Cu 2+ =4Cu + +Fe 2+ +2S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com