Method for quickly keeping heat displacement of spindle constant

A thermal displacement and spindle technology, which is applied in metal processing mechanical parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of long time required, reduced machine tool processing efficiency, long time required for constant thermal displacement, etc., to achieve The effect of ensuring high-precision operation and improving the machining efficiency of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

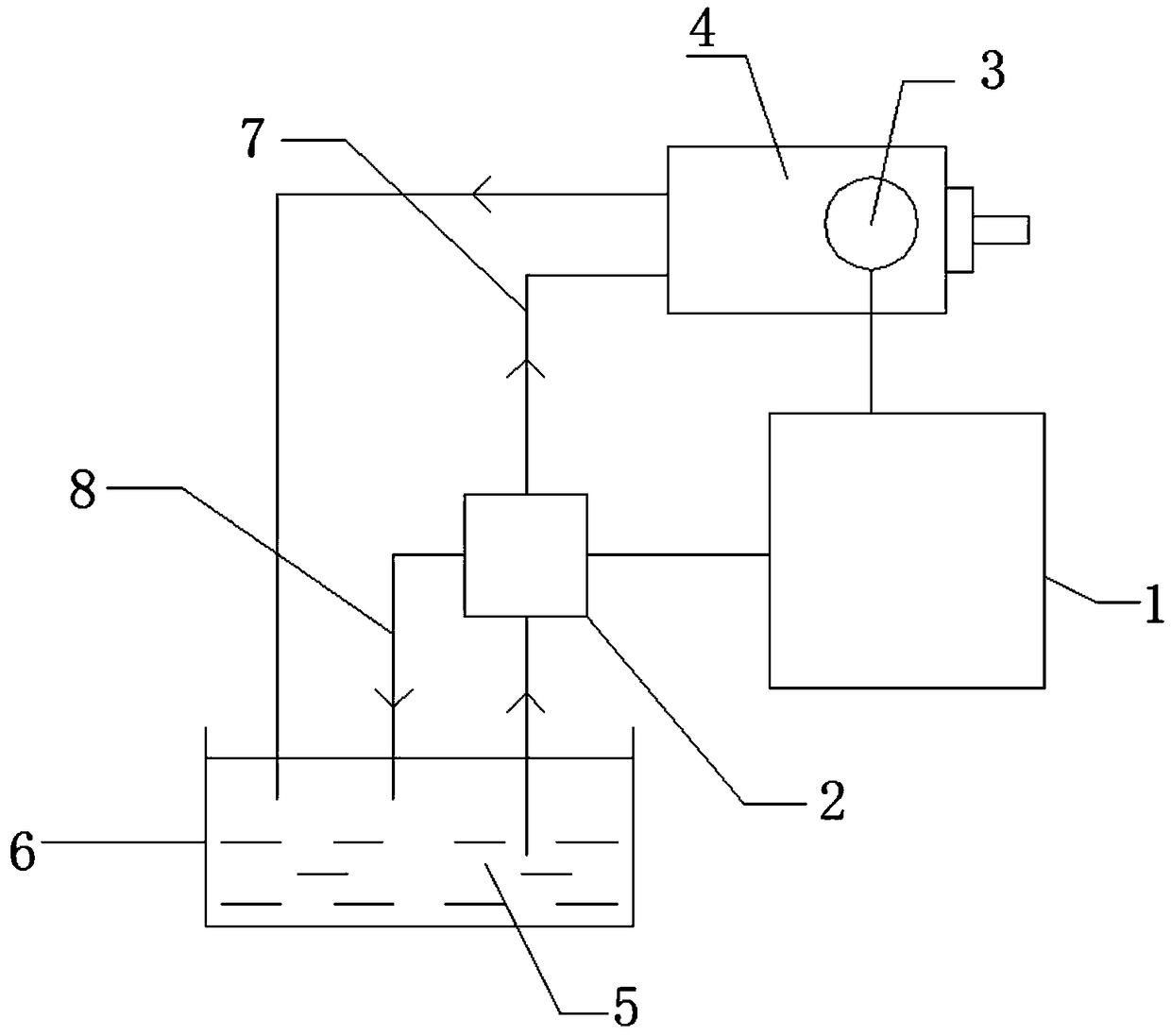

Image

Examples

Embodiment 1

[0035] This embodiment is aimed at the situation that each working state of the spindle can be cooled to the temperature setting value A degree (such as 25 degrees) by the cooling medium with a set temperature (such as a lower temperature of 5 degrees). In this case, the cooling system quickly stabilizes the thermal displacement of the spindle as follows:

[0036] a. In each working state of the spindle, the cooling medium with a set temperature (such as 5 degrees) can cool the spindle to the temperature setting value A degree (such as 25 degrees):

[0037] a1. When the spindle is started in a certain working state (such as S3000 rpm), if the temperature of the spindle is less than or equal to the temperature setting value A degree (such as 25 degrees), the control system will issue an instruction to make the spindle stop cooling state.

[0038] a2. When the main shaft is running after step a1 or when the main shaft starts and runs in a certain working state (such as S1000 ro...

Embodiment 2

[0044] This embodiment aims at the situation that the cooling medium at a lower temperature (such as 5 degrees) cannot be cooled to the temperature setting value A degrees (such as 25 degrees) in each working state of the spindle. In this case, the cooling system quickly stabilizes the thermal displacement of the spindle as follows:

[0045] b. In each working state of the main shaft, the cooling medium with a set temperature (such as 5 degrees) cannot cool the main shaft to the temperature setting value A degree, pre-set the main shaft in each working state in the control system The corresponding target constant temperature X degrees, that is, the target constant temperature X degrees corresponding to each fixed value rotation speed of the spindle is set in the control system in advance:

[0046] b1. When the spindle is started in a certain working state (such as S9000 rpm), if the temperature of the spindle is lower than the target constant temperature X degree (such as 30 d...

Embodiment 3

[0055] This embodiment is aimed at the situation that the spindle cannot be cooled to the temperature setting value A by setting the cooling medium at a lower temperature (such as 5 degrees) in some working states of the spindle (for example, the same temperature of the spindle and the ambient temperature is 25 degrees). In this case, the cooling system quickly stabilizes the thermal displacement of the spindle as follows:

[0056] c. Set the temperature of the cooling medium (such as 5 degrees) to be constant, and the cooling medium at the set temperature (such as 5 degrees) cannot cool the spindle to the temperature setting value A degrees in part of the working state of the spindle (such as a fixed value speed). (For example, 25 degrees), in the control system, set the fixed value speed of the spindle and the corresponding target constant temperature:

[0057] c1. If the main shaft is working in a state where the cooling medium at a set temperature (such as 5 degrees) can c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com