Quicklime slaking apparatus and method used for coke oven flue gas desulphurization

A coke oven flue gas and quicklime technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of excessive agglomeration, short-circuit of the tank in the discharge area, insufficient and other problems, so as to improve the effect of the desulfurization process , Strengthen the stirring ability, enhance the effect of solid-liquid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

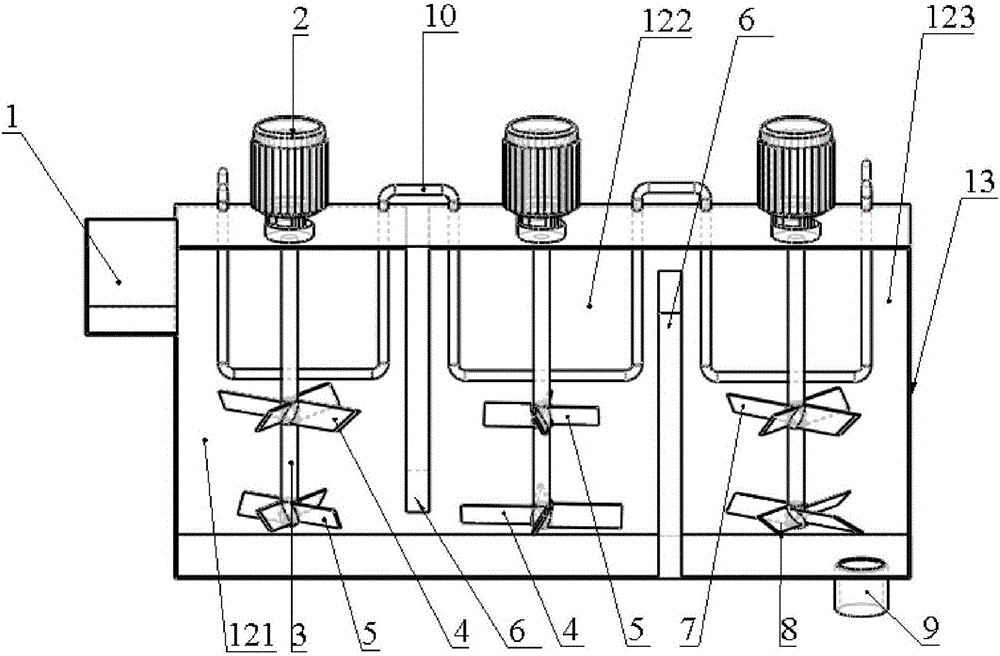

[0036] Such as figure 1 As shown, the number of partitions 6 is 2 (even), and the inner cavity of the digestion tank 13 is divided into 3 (odd) regions. Two adjacent partitions 6 are staggered up and down, a feed port 1 is provided at one end of the digestion tank body 13, and the discharge port is provided at the lower part of the discharge end of the digestion tank.

[0037] First, a certain amount of process water is injected into the digestion tank body 13, and the injected process water is heated to a certain temperature through the heat exchange pipe 10. Then, the quicklime raw material is put into the feed port 1. The quicklime and water start to react in the tank.

[0038] Driven by the motor 2, the stirring shaft 3 rotates at a high speed, driving the paddle on the stirring shaft 3 to stir the lime slurry, so that the quicklime raw material and the water react more evenly. In the first region 121, the stirring shaft 3 rotates counterclockwise, the upper blade 4 with a la...

Embodiment 2

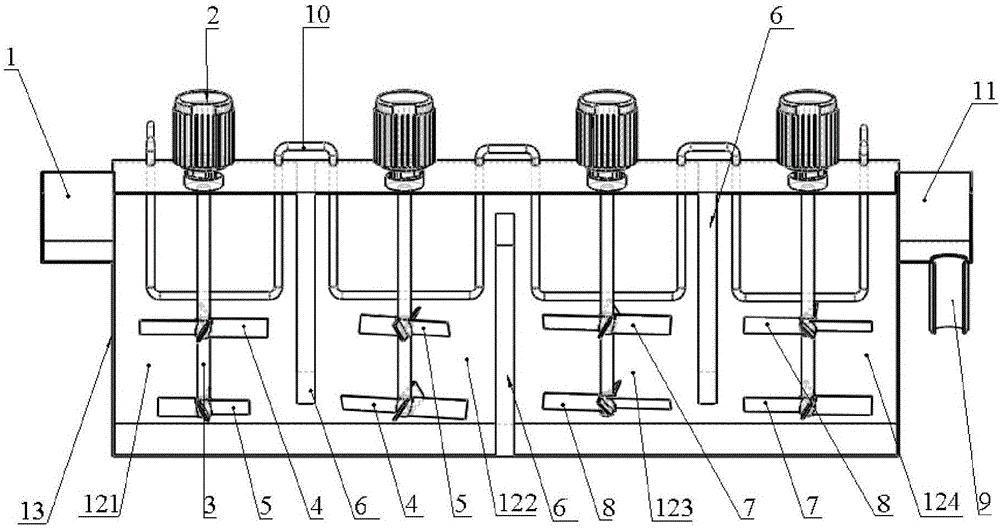

[0041] see figure 2 , The number of partitions is 3 (odd number), and the inner cavity of digestion tank 13 is divided into 4 (even number) areas. Two adjacent partitions 6 are arranged staggered up and down, and the discharge port 11 of the digestion tank body is arranged at the upper part of the discharge end of the digestion tank.

[0042] Compared with Embodiment 1, Embodiment 2 has one more partition 6 and an additional area—a fourth area 124. The stirring device in the fourth region 124 rotates clockwise, the force of the blade 8 with a smaller pitch angle on the fluid is downward, and the force of the blade 7 with a larger pitch angle on the fluid is upward. However, due to the larger pitch angle of the blades 7, the overall flow trend of the fluid is upward, from the fourth area 124 to the discharge port 11, and finally out of the discharge port pipe 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com