Temperature control system of stirring kettle for material mixing

A technology of temperature control system and stirred tank, which is applied in the direction of dissolution, dissolution, chemical instruments and methods, etc., can solve the problem of limited cooling water cooling temperature range, limited cooling water capacity and flow rate, and seasonal environmental temperature changes of the jacket cooling system No strain and other problems, to achieve stable production process, solve the effect of poor thermal conductivity and good constant temperature treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

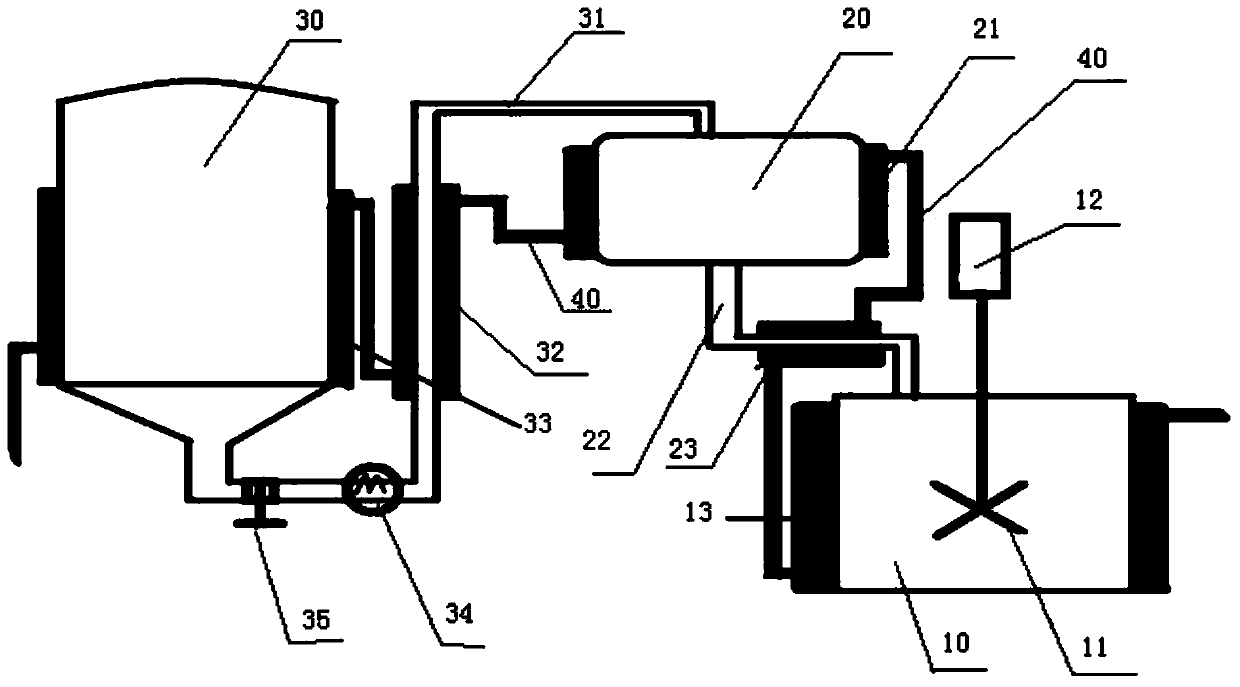

[0023] Disclose a kind of temperature control system of mixing material stirring tank in the present embodiment, such as figure 1 As shown in , it includes a mixing and stirring tank 1, a first raw material storage tank 20 and a second raw material storage tank 30, and the above mixing and stirring tank 1 and the above-mentioned first raw material storage tank 20 are connected by a first delivery pipeline 22, The first raw material storage tank 20 and the second raw material storage tank 30 are connected by a second delivery pipeline 31 .

[0024] The outside of the mixing and stirring tank 1 is provided with a cooling jacket for cooling the mixing temperature inside the mixing and stirring tank, the outside of the above-mentioned first delivery pipeline 22 is provided with a first heat exchange device 23, and the outside of the above-mentioned first raw material storage tank 20 is provided with The second heat exchange device 21 , the third heat exchange device 32 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com