Automatic temperature control ventilation cabinet

A fume hood and cabinet technology, applied in the field of laboratory equipment, can solve problems such as hidden safety hazards, temperature rise, incomplete discharge of toxic and harmful gases, etc., and achieve the effect of ensuring safety and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

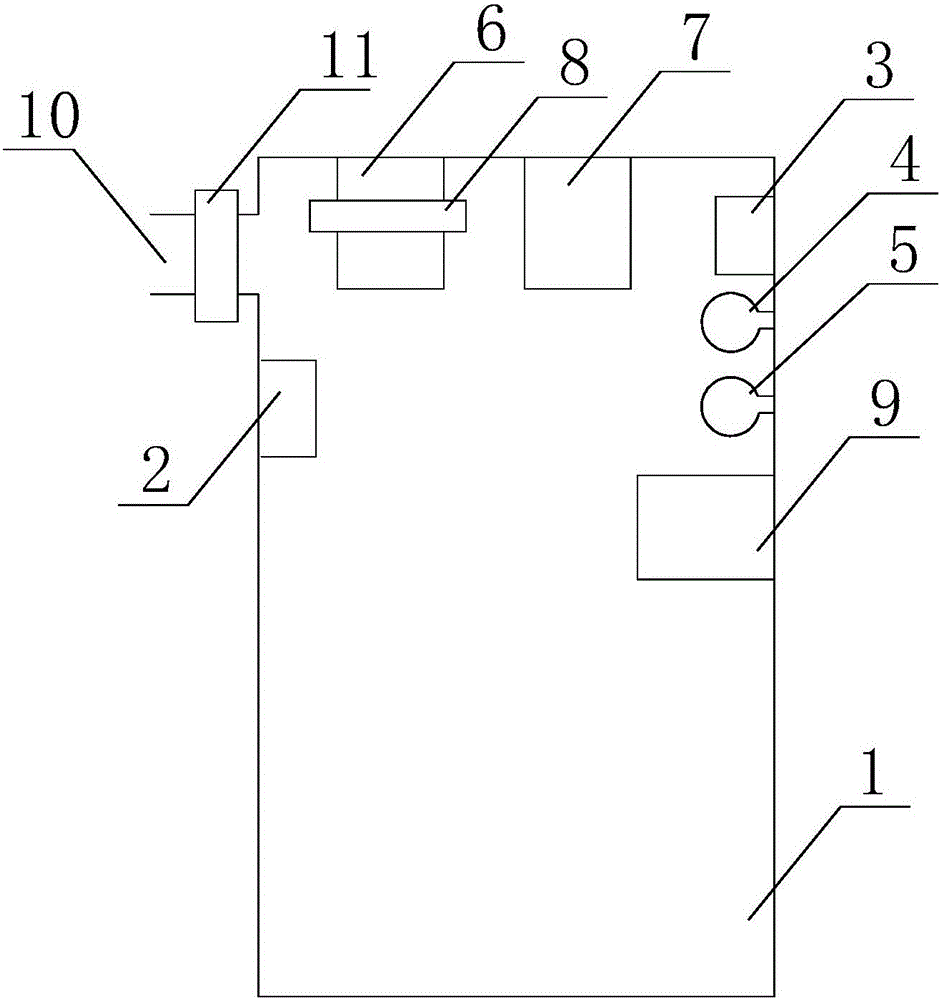

[0020] like figure 1 , figure 2 as shown, figure 1 , figure 2 It is an automatic temperature control fume hood proposed by the present invention.

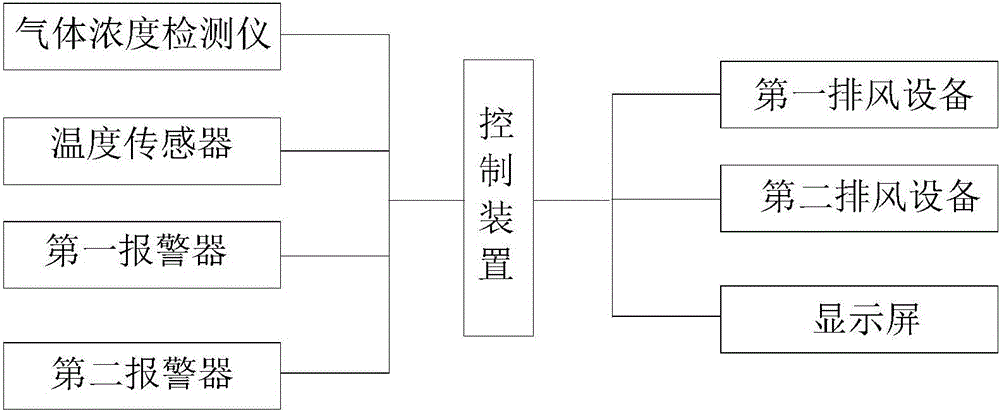

[0021] refer to figure 1 , figure 2 , the automatic temperature control fume hood that the present invention proposes, comprises: cabinet body 1, exhaust device, warning device and control device;

[0022] The inside of the cabinet 1 is provided with a gas concentration detector 2 for detecting the concentration of toxic and harmful gases in the cabinet 1; the inside of the cabinet 1 is provided with a temperature sensor 3 for detecting the internal temperature of the cabinet 1;

[0023] The cabinet body 1 is provided with an air outlet 10, and the air outlet 10 is provided with a filter device 11, and the filter device 11 includes: an acid absorption layer, an alkali absorption layer, an activated carbon absorption layer and a drying layer. It is used to absorb and discharge the toxic and harmful gas generated in the cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com