21/4Cr-1Mo-1/4V steel forging and automatic temperature-control inflation three-dimensional circulating water rapid cooling thermal treatment method thereof

A 4cr-1mo-1, heat treatment method technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of reducing the performance of reactor materials, reducing service life, increasing the volume and capacity of hydrogenation reactors, etc. Achieve the effect of improving hydrogen corrosion resistance, increasing stability, and improving stress strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

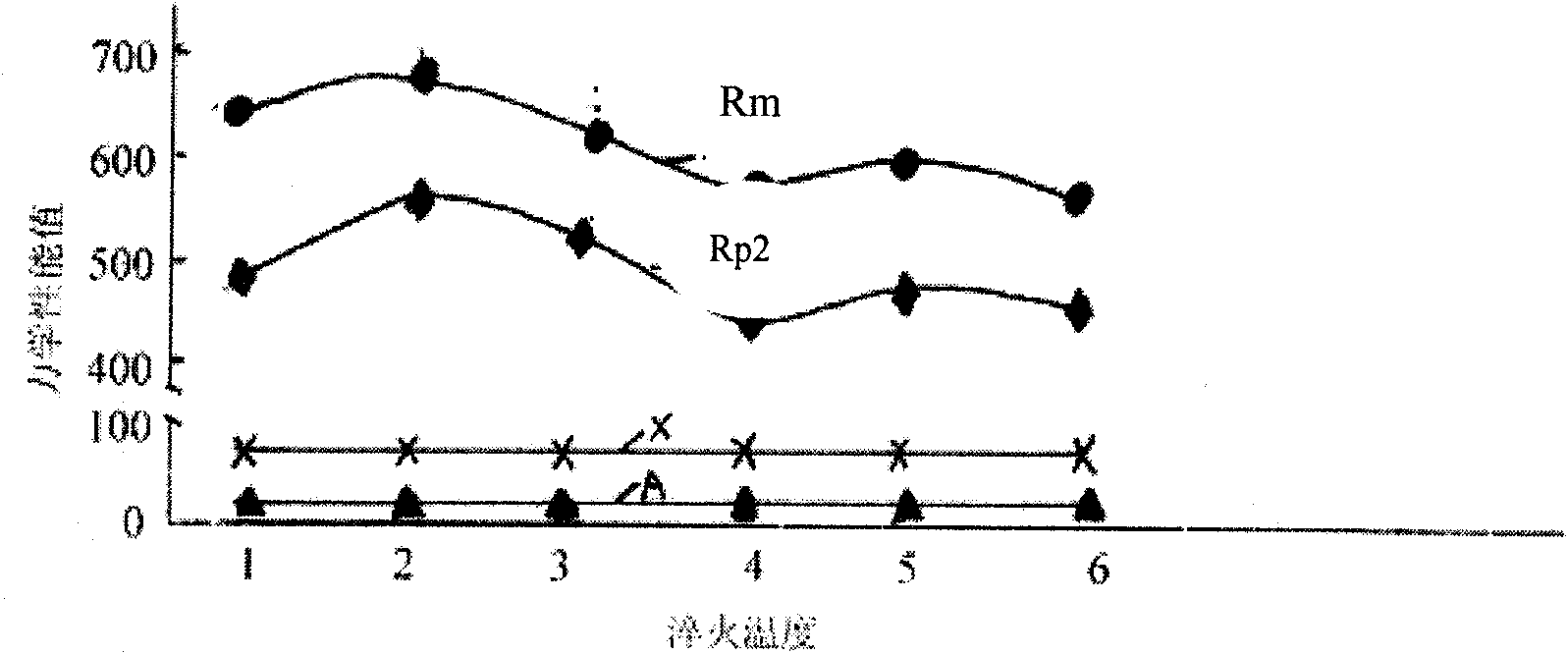

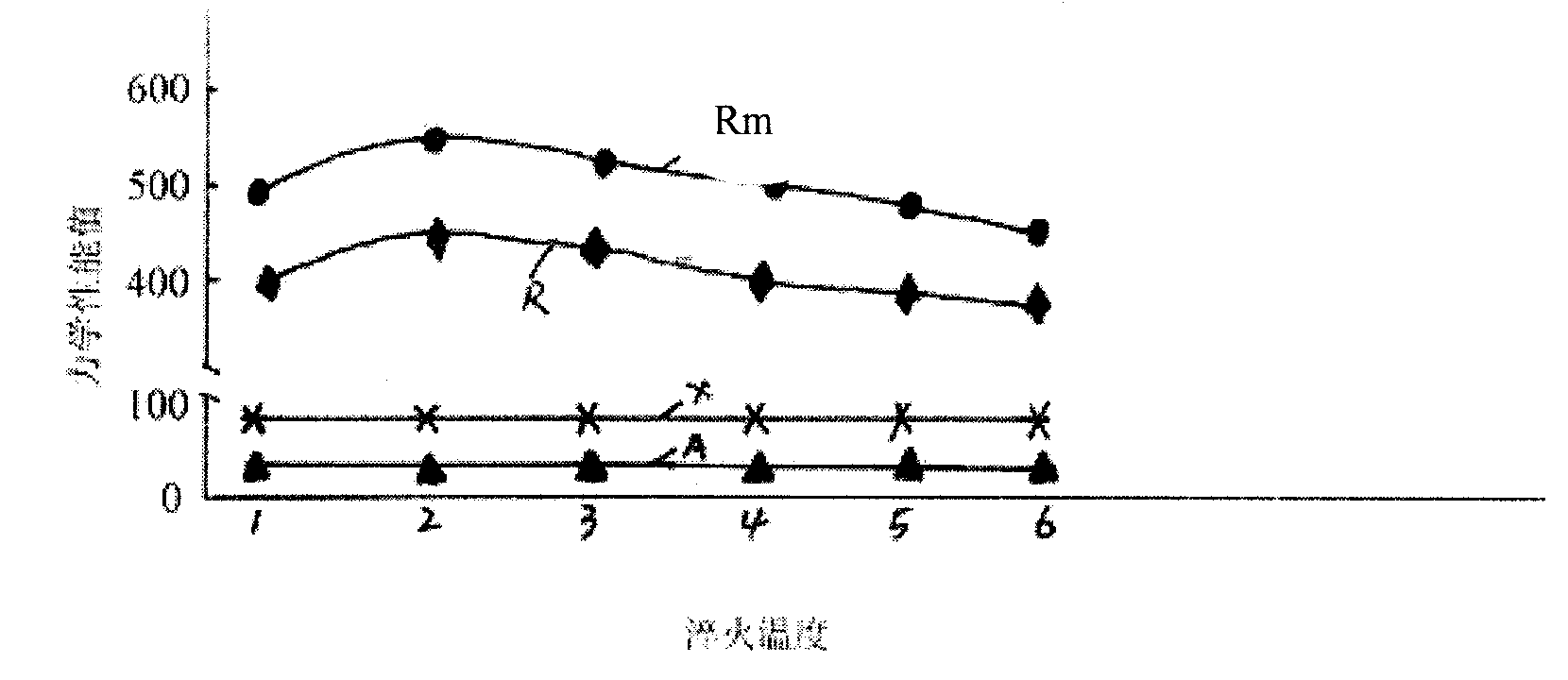

[0022] In order to improve the comprehensive mechanical properties of 21 / 4Cr-1Mo-1 / 4V steel forgings in the actual manufacturing process, we conducted experimental research on its heat treatment process.

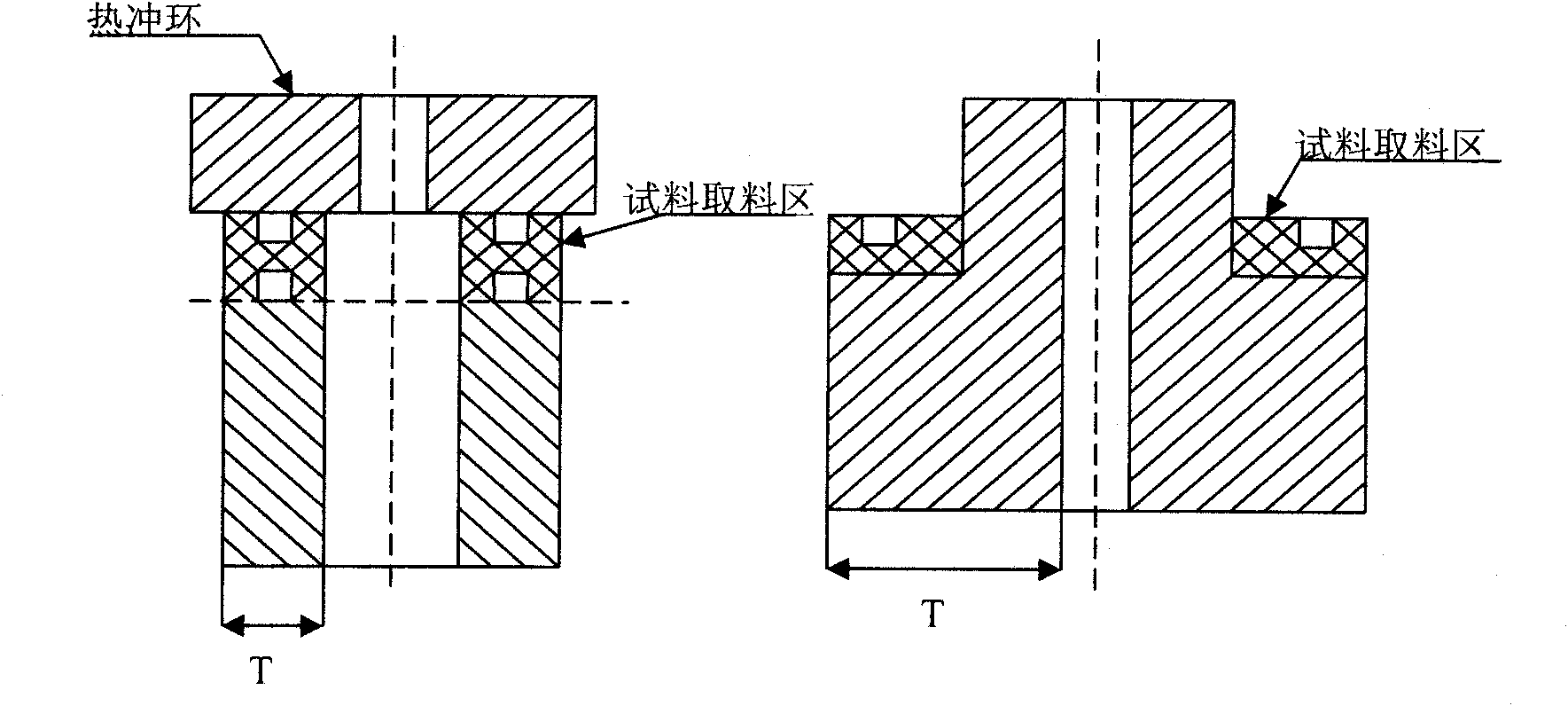

[0023] Among the hydrogenation reactor accessories recently produced by our company, there are four pieces of 21 / 4Cr-1Mo-1 / 4V steel flanges, the nominal size of which (such as figure 1 ) The technical conditions require testing the performance of the central part of the forging (outside T / 2), which is quite difficult to manufacture.

[0024] 2 main technical indicators

[0025] The chemical composition of 21 / 4Cr-1Mo-1 / 4V steel forgings is shown in Table ①

[0026] C

Si

mn

P

S

Cr

Mo

Ni

Cu

V

Ti

B

Nb

Ca

0.11-0.15

≤0.10

0.30-0.60

≤0.010

≤0.010

2.00-2.500

0.9-1.10

≤0.20

≤0.150

0.25-0.35

≤0.30

≤0.0020

≤0.07

≤0.015

[0027] The mechanical property require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com