Ultrasonic detecting method of hydrogen damage of water cooling wall tube of boiler

A technology for a water-cooled wall tube and a detection method, which is applied in the directions of using ultrasonic/sonic/infrasonic waves, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Disappearance of pearlite, decarbonization and other problems, to achieve the effect of improving portability, simple steps, and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

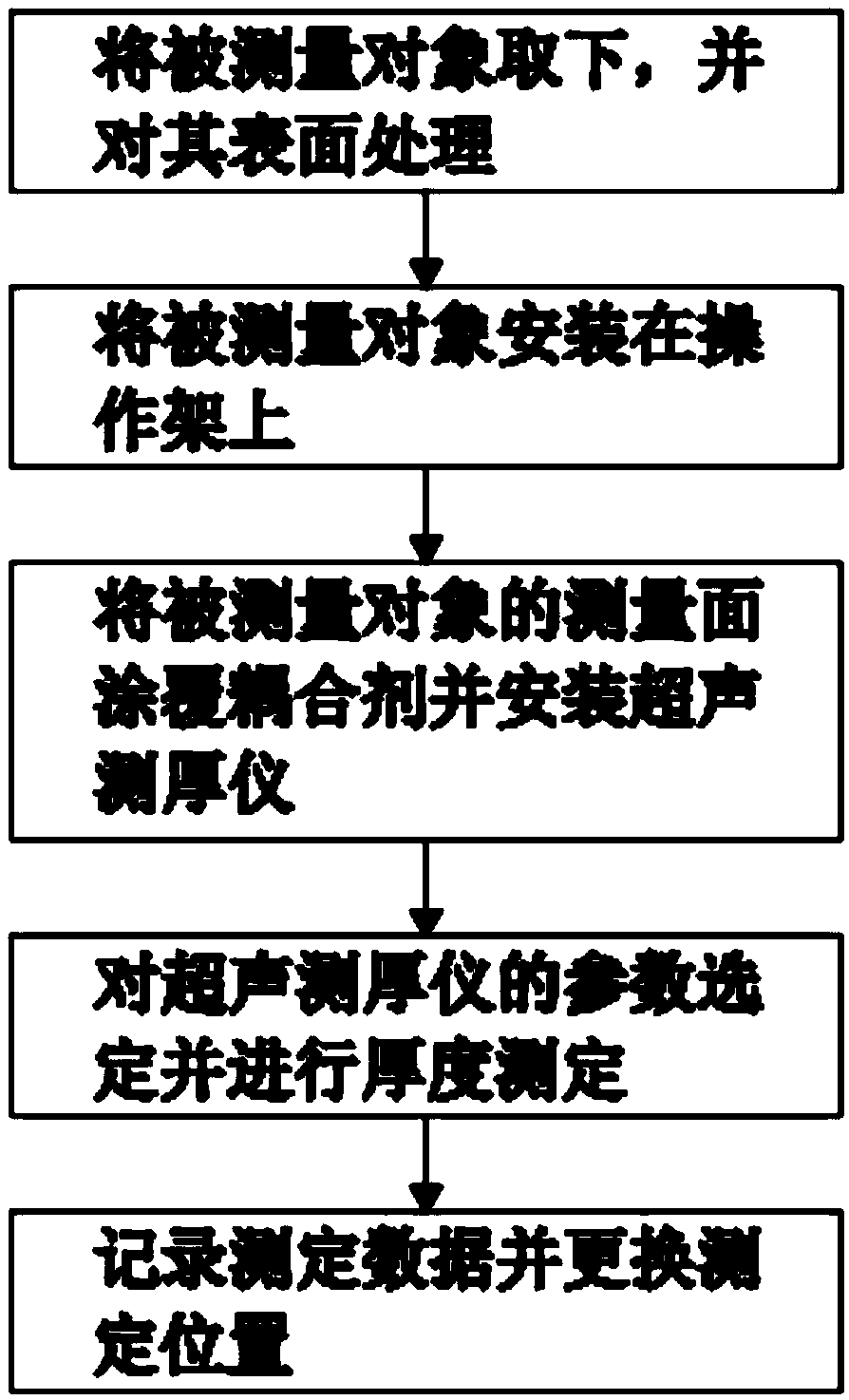

Method used

Image

Examples

Embodiment

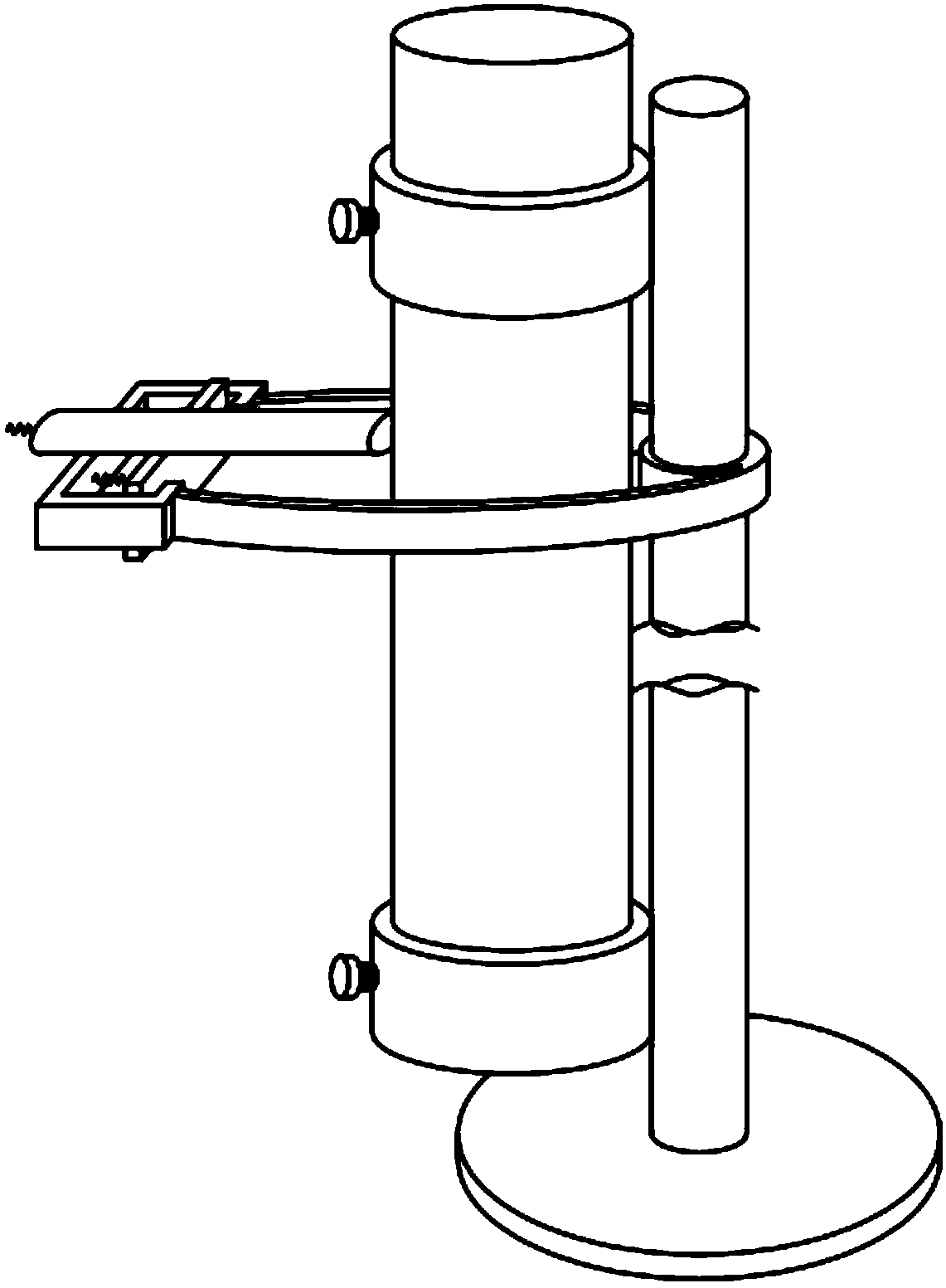

[0028] Such as image 3 As shown, the water-cooled wall tube is inserted between the upper and lower sets of bushing assemblies 2, fixed by screws, and the probe is clamped on the probe clamping plate 6.

[0029] Select the QU1600 ultrasonic thickness gauge as the measuring instrument, the measurement range is (0.75-300) mm, and it is connected with RS232 interface, which is convenient to connect with the PC terminal. The damage of the water-cooled wall tube is roughly the same. Sampling is enough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com