Method for detecting material hydrogen damage through ultrasonic surface waves

An ultrasonic surface wave and material detection technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve problems such as inability to determine well, inconvenient body wave detection, and different materials, and achieve safety and equipment maintenance. Active, saving manpower and material resources, and the effect of flexible instrument operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. However, it should be noted that implementation of the present invention is not limited to the following embodiments.

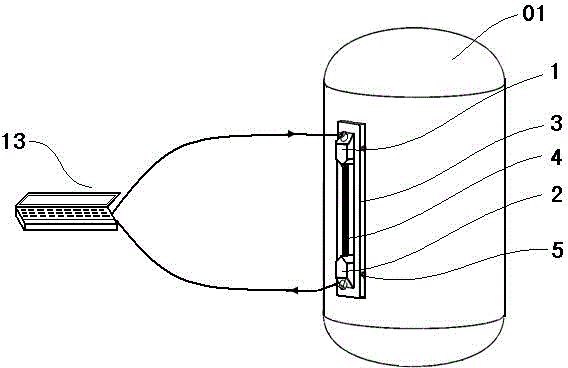

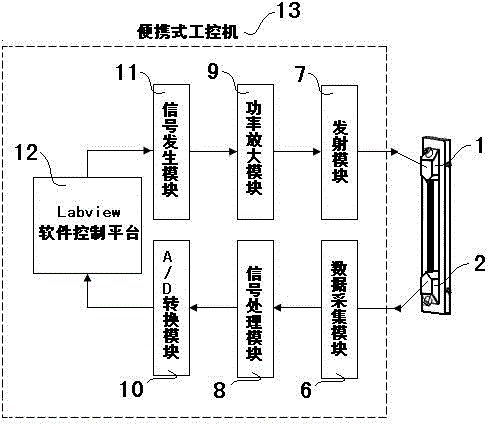

[0043] see figure 1 . A device for detecting hydrogen damage to materials through ultrasonic surface waves, comprising a high-frequency ultrasonic surface wave transmitting probe 1 , a high-frequency ultrasonic surface wave receiving probe 2 , a substrate 3 , guide rails 4 , positioning nuts 5 and a portable industrial computer 13 .

[0044] Set the high-frequency ultrasonic surface wave transmitting probe 1 and the high-frequency ultrasonic surface wave receiving probe 2 on the same guide rail 4 in the middle of the substrate 3, and use different positioning nuts 5 to fix them on the guide rail 4 respectively and maintain a certain distance. The high-frequency ultrasonic surface wave transmitting probe 1 and the high-frequency ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com