Surface adsorption hydrogen rapid detection method of high-strength steel hydrogen damages

A surface adsorption and detection method technology, applied in the direction of material electrochemical variables, etc., can solve the problems of inability to quickly detect, unfavorable engineering hydrogen damage detection application, long test time, etc., and achieve accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The reliability of the present invention is described in detail below in conjunction with accompanying drawing and an example:

[0025] (1) Material to be tested: 10CrSiNiCu low-alloy high-strength steel. Use water-grinding sandpaper to grind the sample step by step to 2000, clean it with acetone and deionized water, and dry it with hot air;

[0026] (2) Hydrogen filling solution: 3.5% NaCl solution with pH=2.00 as corrosion medium, and boric acid (50 grams per liter) was added as buffer solution;

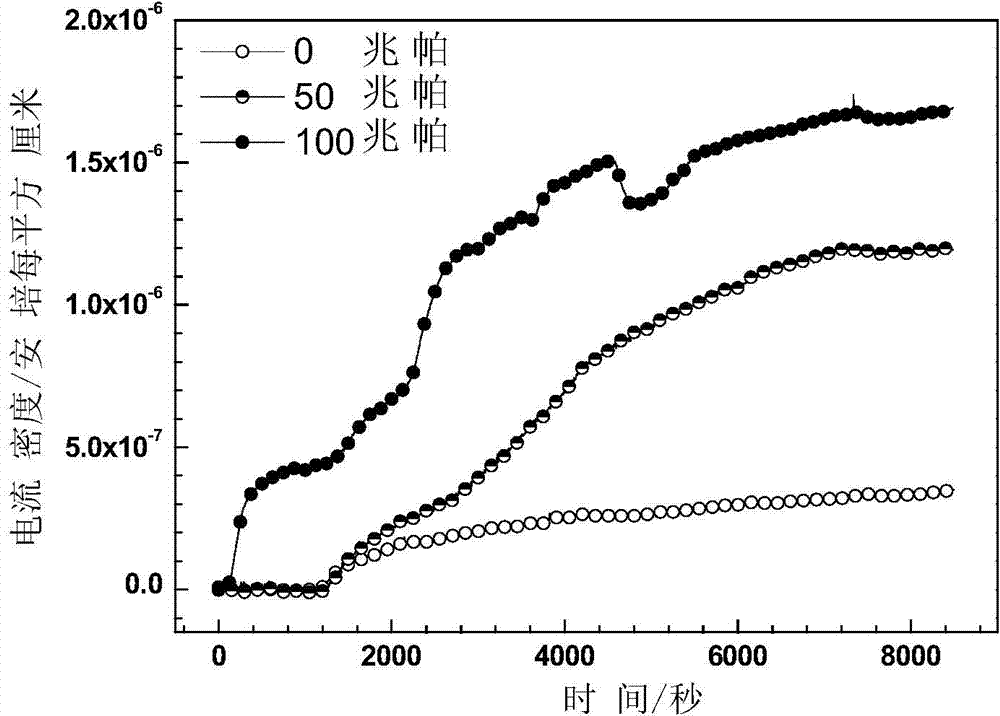

[0027] (3) Experimental parameters: Under the external tensile stress of 0 MPa, 50 MPa, and 100 MPa, respectively, the inductance and resistance of hydrogen adsorption, hydrogen permeation steady-state hydrogen permeation current, and fracture mechanical properties corresponding to different conditions were tested;

[0028] (4) Test results:

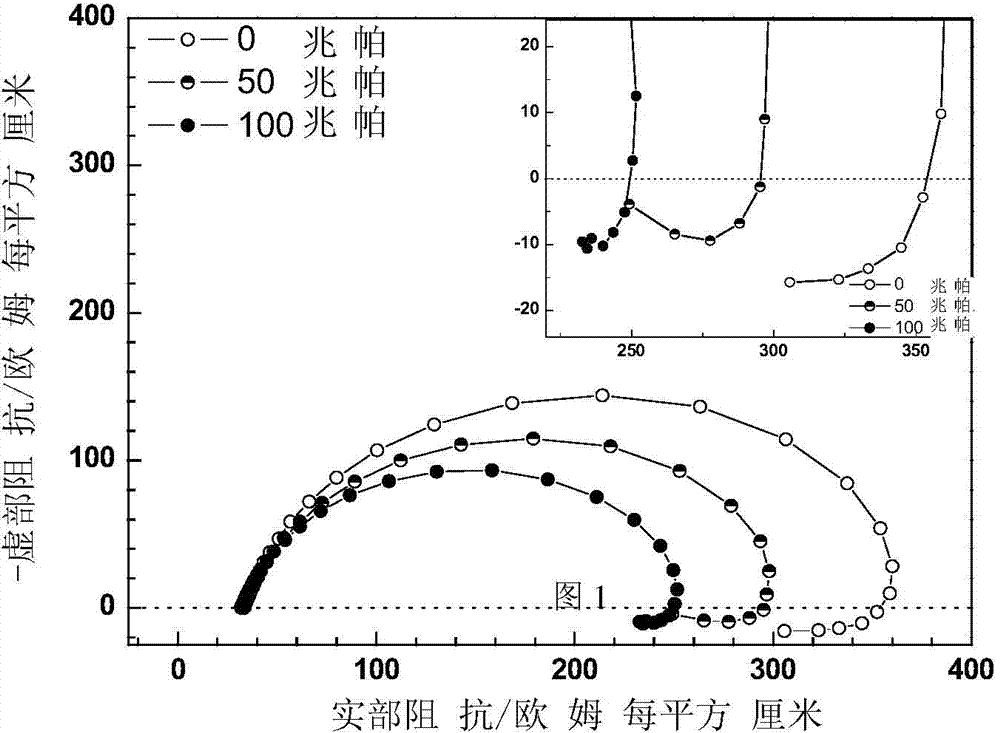

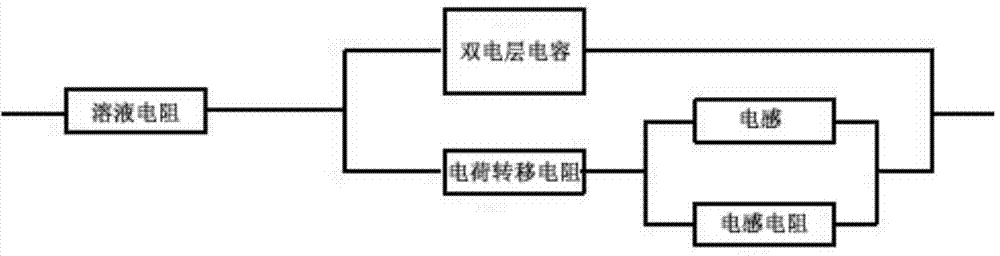

[0029] 1. Electrochemical impedance spectroscopy test: from figure 1 It can be seen intuitively that the intuitive impedance Nyquis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com