Ultrasonic detection and diagnosis method for hydrogen damages on water-cooling wall pipe of boiler

A water-cooled wall tube and ultrasonic technology, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of difficult detection, low efficiency and low accuracy, and achieve the effect of improving measurement efficiency, simple principle and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

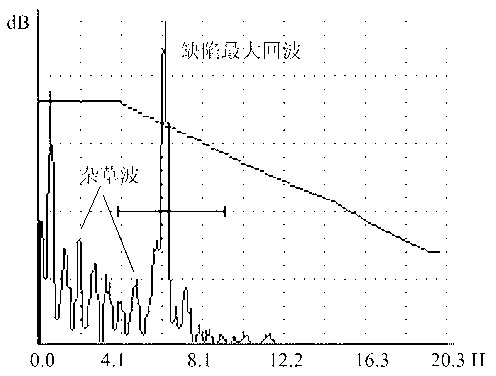

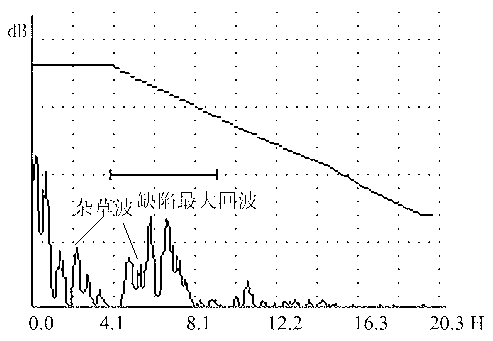

[0021] The inventive method comprises the following steps:

[0022] Step 1. Select a pipe with the same outer diameter as the boiler water wall pipe to be tested and diagnosed as the tested pipe sample, for example, the material is 20G, and the specification is Φ60×6.5mm;

[0023] Step 2. The ultrasonic testing instrument is Hanwei HS610e produced by Wuhan Zhongke Innovation Technology Co., Ltd. The probe adopts A-type pulse reflection shear wave oblique probe, the probe specification is 5P6×6K1, the coupling agent is engine oil, and the surface compensation is 0dB. Grind the shear wave probe according to the outer diameter of the tested pipe sample, so that the probe is in close contact with the detection surface;

[0024] Step 3. Prepare DL-1 type special test block according to the requirements of DL / T820 "Technical Regulations for Ultrasonic Inspection of Pipeline Welded Joints" according to the same type of material of the boiler water wall tube to be tested and diagnosed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com