Method for preventing pipeline hydrogen damage, and oil transfer line and manifold of oil refining and hydrogen production reformer applying method

A technology of manifolds and oil transfer lines, which is applied in the direction of preventing damage/wear of pipelines, pipeline protection, pipes/pipe joints/fittings, etc. The effect of fatigue tendency and standing wave hazards, long service life and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

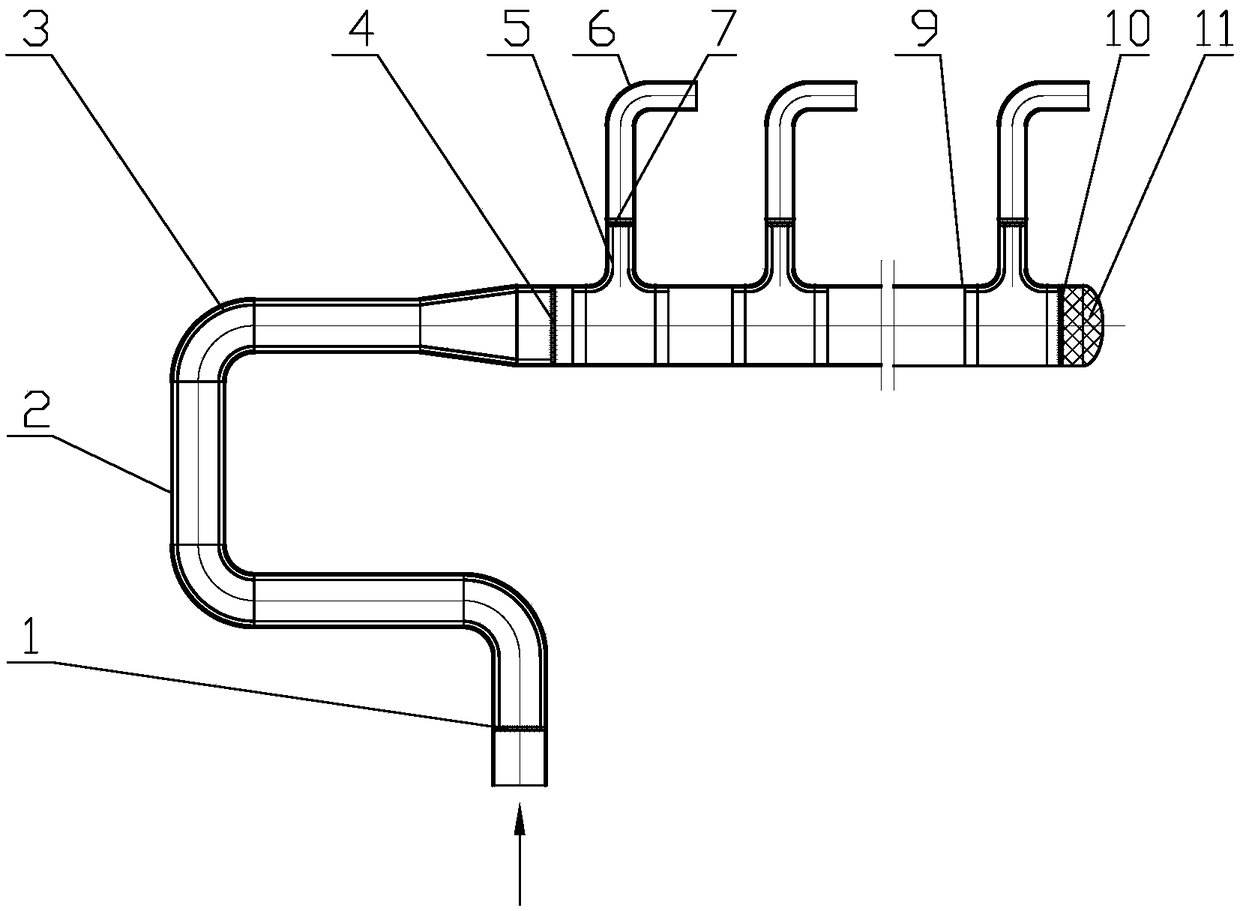

Embodiment 1

[0037] like figure 1 As shown: the inner wall of the U-shaped oil transfer line 2 is provided with a hollow isolation layer 3, the inlet end and the outlet end are respectively provided with an orifice plate 1 and an orifice plate 4, and the end of the collecting pipe 9 is provided with an orifice plate 10 and a packing 11, A plurality of branch pipes 6 are connected to the side of the collecting pipe 9, the lower part of the branch pipes 6 and the inner wall of the connection between the branch pipes 6 and the collecting pipe 9 are provided with a hollow isolation layer 5, and the branch pipes 6 are provided with orifice plates 7.

[0038] The isolation layer 3 and the isolation layer 5 of this embodiment are hollow liners or bushings, which can effectively reduce the damage of hydrogen to the pipeline. 3. The function of the isolation layer 5 and the filler 11 does not affect the flow of the material at the same time. The filler 11 acts as a buffer, which can effectively red...

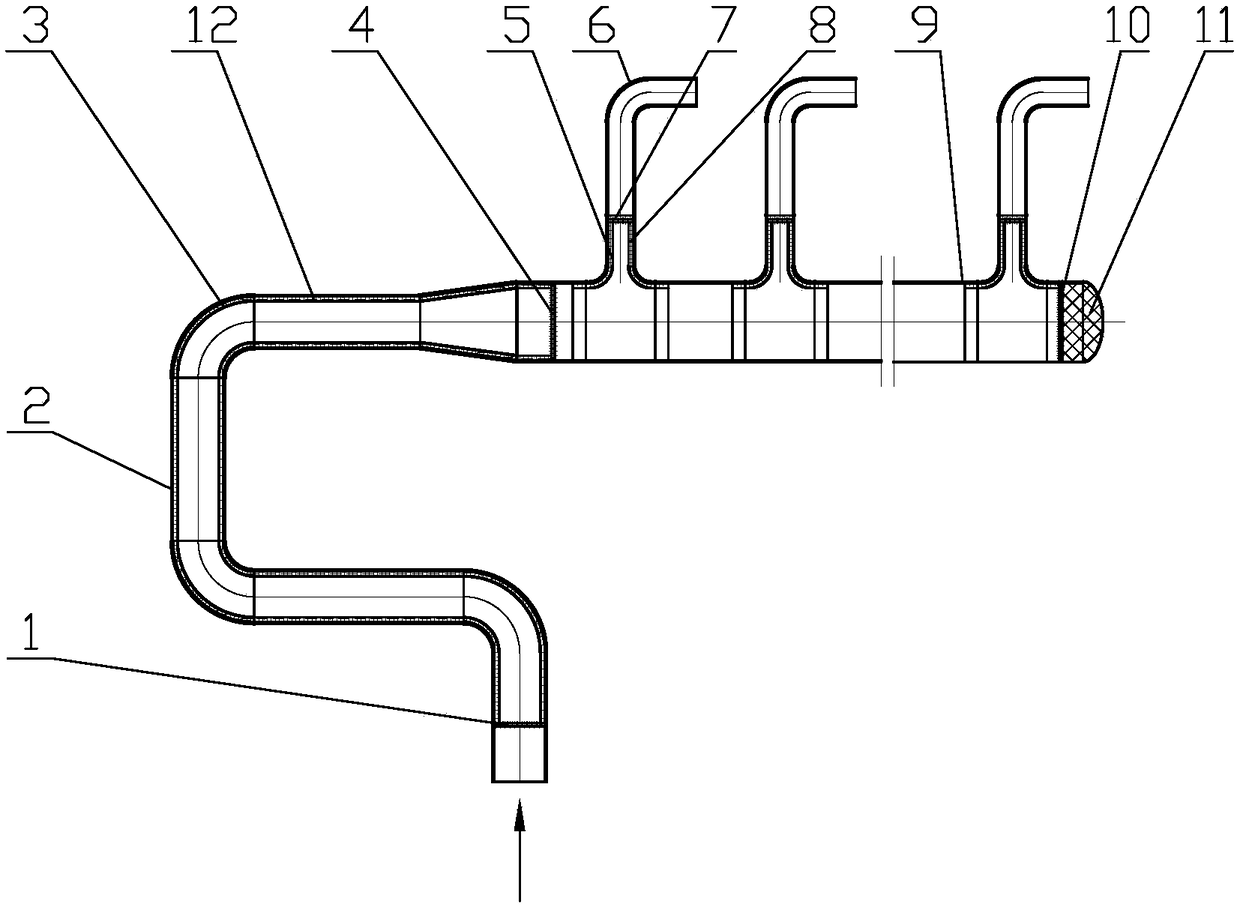

Embodiment 2

[0040] like figure 2 As shown: the isolation layer 3 and the isolation layer 5 are respectively provided with a filler 12 and a filler 8, and the others are the same as in the first embodiment.

[0041] Compared with Example 1, this embodiment adds filler 12 and filler 8, and the isolation effect is better.

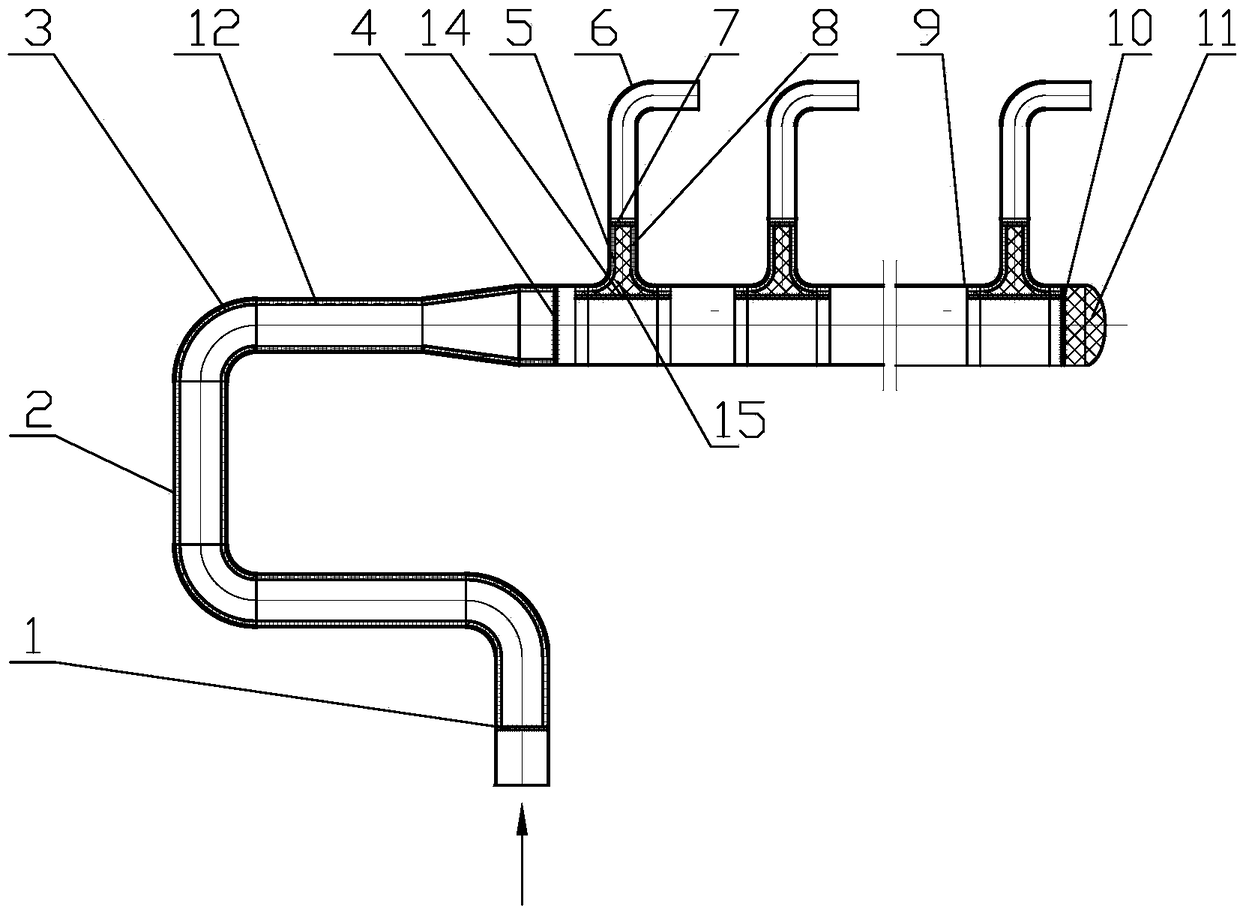

Embodiment 3

[0043] like image 3 Shown: the inside of the pipeline at the isolation layer 5 is provided with a filler 15, in order to fix the filler 15, an orifice 14 is arranged below it, and the others are the same as in embodiment 2

[0044] Compared with Embodiment 2, this embodiment adds fillers 15 to better protect the branch pipe 6 and the connection between the branch pipe 6 and the manifold 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com