Environment-friendly explosion-resistant material for rapidly and efficiently inhibiting hydrogen explosion

An environmentally friendly, hydrogen-based technology, applied in fire-resistant coatings, alginic acid coatings, mechanical equipment, etc., to achieve high calorific value, easy replacement, and the effect of suppressing detonation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

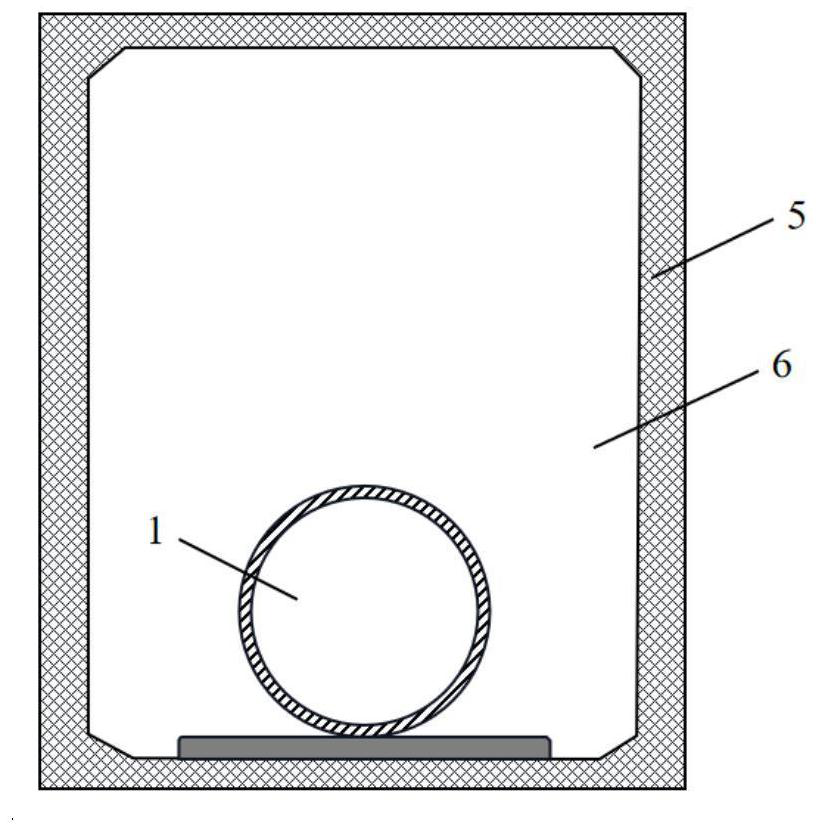

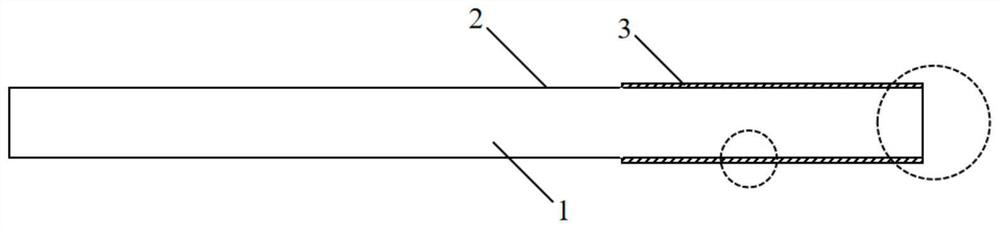

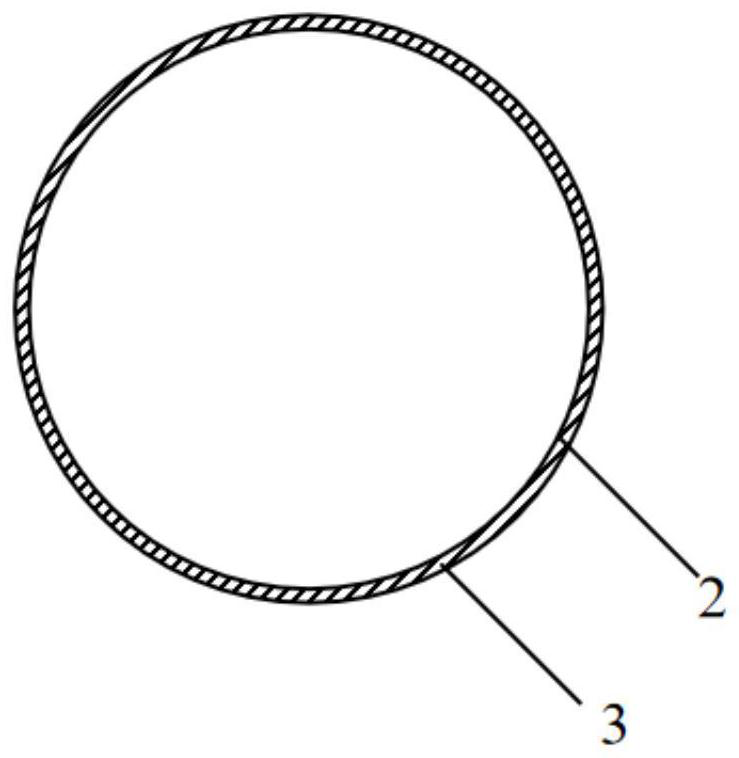

[0027] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings, however, the embodiments of the present invention are not limited thereto. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0028] An environmentally friendly, fast and efficient anti-explosion material for suppressing hydrogen explosion of the present invention includes sodium alginate and sodium silicate. After the components of the anti-explosion material are mixed in equal proportions, pure water is added in a proportion of 2:100. , fully stir and mix it into a gel and apply it to the outer surface of the pipe wall of the test section. After the application is completed, smooth it with a soft ruler, and place the pipe vertically and statically to make the gel cover the pipe wall more evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com