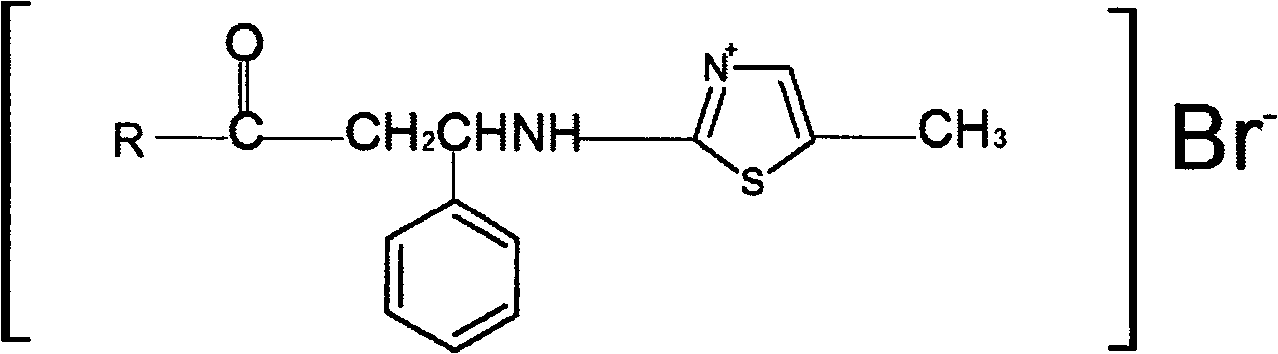

Corrosion inhibitor for controlling corrosion of high-concentration hydrogen sulfide in acid liquor medium and preparation method thereof

A corrosion inhibitor and high-concentration technology, applied in earthwork drilling, organic chemistry, wellbore/well components, etc., can solve the problems of unsatisfactory hydrogen stress corrosion effects, achieve excellent corrosion inhibition performance, enhance adsorption capacity, combine good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

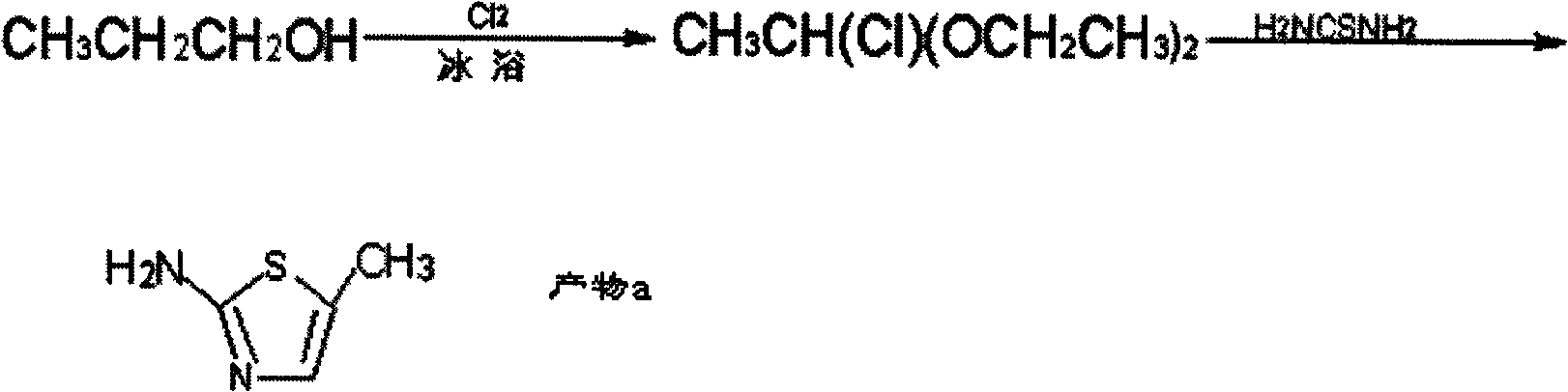

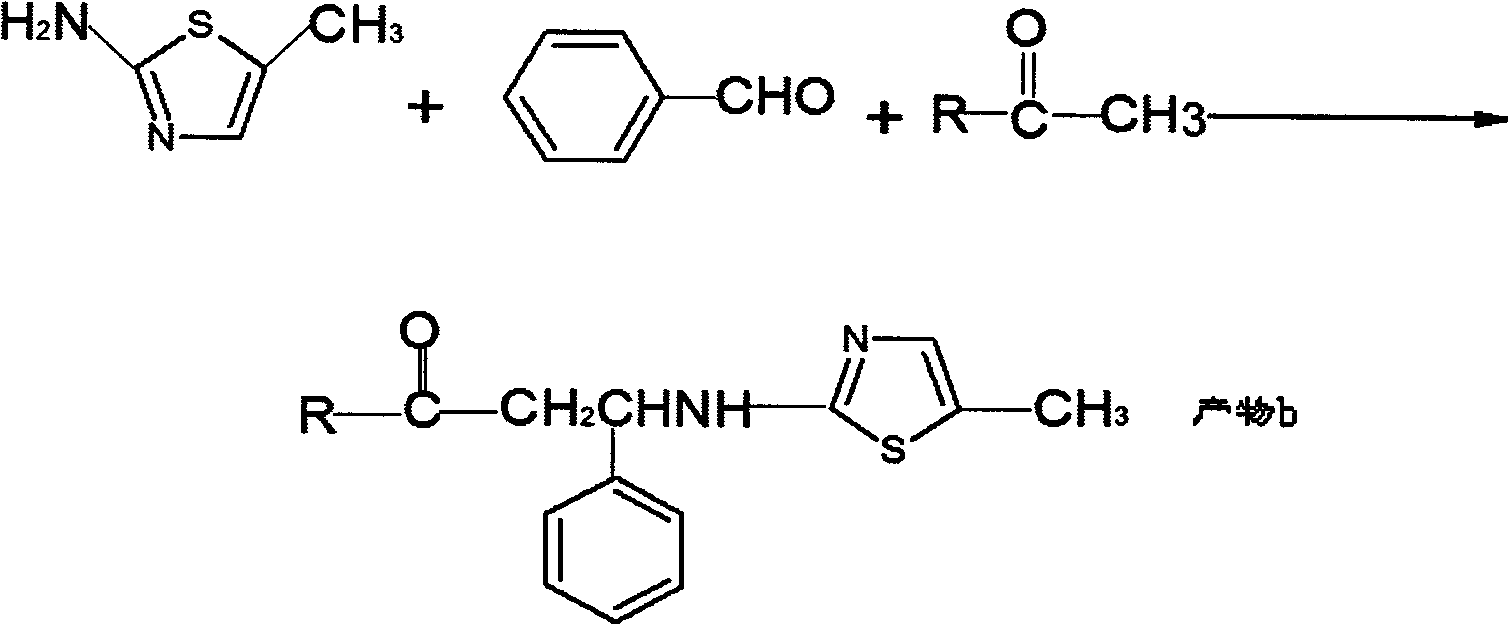

[0043] The first step: Synthesis of 2-amino-5-methylthiazole:

[0044] Add 73.6g of n-propanol and 3.2g of water into a 250mL three-necked bottle equipped with a thermometer, stirrer, air guide tube, tail gas tube and an alkali absorption bottle, weigh and record. At 10°C (if necessary, cool with water or ice water), slowly introduce chlorine gas, and start the stirrer to stir. When the weight of the three-necked bottle reaches 24.5g-49g, stop the chlorine gas flow. The cumulative time for chlorine gas injection is From 2h to 4h, the amount of chlorine gas introduced is 1 / 3mol. Separate the heavy layer, add 10.5 g of a mixture of thiourea and water with a weight ratio of 2.5:1, heat up to 60-90°C and heat to reflux, and simultaneously use copper sulfate test solution or thin-layer chromatography to detect the reaction. The reaction time is about 4 After ~5h, propanol was recovered by distillation, and an oily substance was obtained in the three-necked flask. Add 2.1 g of wat...

Embodiment 2

[0051] The first step: Synthesis of 2-amino-5-methylthiazole:

[0052] Add 73.6g of n-propanol and 3.2g of water into a 250mL three-necked bottle equipped with a thermometer, stirrer, air guide tube, tail gas tube and an alkali absorption bottle, weigh and record. At 10°C (if necessary, cool with water or ice water), slowly introduce chlorine gas, and start the stirrer to stir. When the weight of the three-necked bottle reaches 24.5g-49g, stop the chlorine gas flow. The cumulative time for chlorine gas injection is From 2h to 4h, the amount of chlorine gas introduced is 1 / 3mol. Separate the heavy layer, add 10.5 g of a mixture of thiourea and water with a weight ratio of 2.5:1, heat up to 60-90°C and heat to reflux, and simultaneously use copper sulfate test solution or thin-layer chromatography to detect the reaction. The reaction time is about 4 After ~5h, propanol was recovered by distillation, and an oily substance was obtained in the three-necked flask. Add 2.1 g of wat...

Embodiment 3

[0058] The first step: Synthesis of 2-amino-5-methylthiazole:

[0059] Add 73.6g of n-propanol and 3.2g of water into a 250mL three-necked bottle equipped with a thermometer, stirrer, air guide tube, tail gas tube and an alkali absorption bottle, weigh and record. At 10°C (if necessary, cool with water or ice water), slowly introduce chlorine gas, and start the stirrer to stir. When the weight of the three-necked bottle reaches 24.5g-49g, stop the chlorine gas flow. The cumulative time for chlorine gas injection is From 2h to 4h, the amount of chlorine gas introduced is 1 / 3mol. Separate the heavy layer, add 10.5 g of a mixture of thiourea and water with a weight ratio of 2.5:1, heat up to 60-90°C and heat to reflux, and simultaneously use copper sulfate test solution or thin-layer chromatography to detect the reaction. The reaction time is about 4 After ~5h, propanol was recovered by distillation, and an oily substance was obtained in the three-necked flask. Add 2.1 g of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com