Steel for ultrahigh-strength marine hose and preparation method of steel

An ultra-high-strength, marine technology, applied in the field of metallurgy, can solve the problems of high strength and stress corrosion cracking resistance, and cannot meet the requirements of sulfide stress corrosion cracking resistance, and achieve energy saving, good hydrogen damage resistance, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A steel for ultra-high-strength marine hose, including components and weight percentages: C 0.07%, Si 0.23%, Mn 0.47%, P 0.005%, S 0.003%, Cr 1.04%, Mo 1.5%, Ni 0.29%, Nb 0.04%, Ti0.015%, and the balance is Fe and unavoidable impurities.

[0032] The preparation method of the steel for the ultra-high-strength marine hose comprises the following steps:

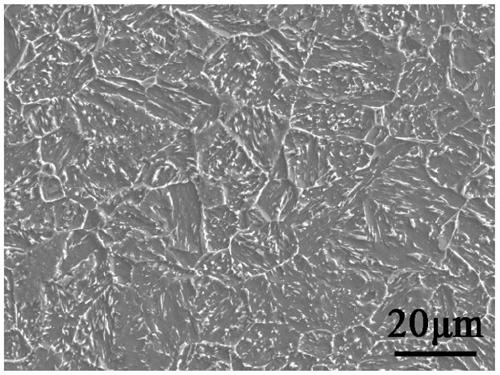

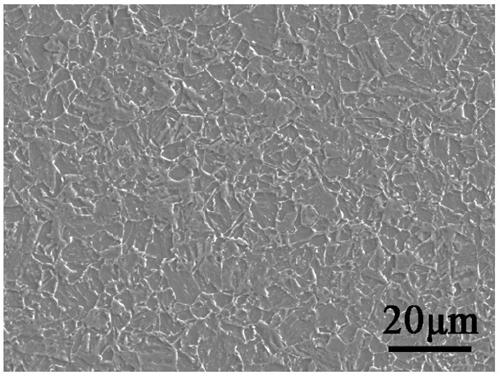

[0033] Smelting, refining and continuous casting into continuous casting slabs according to the set composition, heating the slab to 1200°C and keeping it warm for 40 minutes to homogenize the structure and composition, and then the billet is hot rolled to a Φ10mm wire rod by a high-speed wire rolling mill, and the rolling temperature is 1150 ℃, the final rolling temperature is 940℃, water cooling after rolling, the spinning temperature is 810℃, and the coiling temperature is slowly cooled to 400℃. The microstructure after hot rolling is specifically shown in the electronic probe diagram figure 1 As shown, it is a baini...

Embodiment 2

[0039] A steel for ultra-high-strength marine hose, including components and weight percentages: C 0.1%, Si 0.38%, Mn 0.89%, P 0.008%, S 0.002%, Cr 1.5%, Mo 1.0%, Ni 0.5%, Nb 0.045%, Ti0.015%, the balance is Fe and unavoidable impurities.

[0040] The preparation method of the steel for the ultra-high-strength marine hose comprises the following steps:

[0041]Smelting, refining and continuous casting into continuous casting slab according to the set composition, heating the slab to 1170°C and keeping it warm for 60 minutes to homogenize the structure and composition, and then the billet is hot rolled to a Φ20mm wire rod by a high-speed wire rolling mill, and the rolling temperature is 1140 ℃, final rolling temperature 950 ℃, water cooling after rolling, spinning temperature 830 ℃, slow cooling to coiling temperature 420 ℃;

[0042] The hot-rolled wire rod is cooled to room temperature, and after removing the iron scale, it undergoes 5 passes of cold rolling to obtain the fla...

Embodiment 3

[0047] A steel for ultra-high-strength marine hose, including components and weight percentages: C 0.04%, Si 0.44%, Mn 0.69%, P 0.006%, S 0.002%, Cr 1.41%, Mo 1.26%, Ni 0.2%, Nb 0.036%, Ti0.01%, the balance is Fe and unavoidable impurities;

[0048] The preparation method of the steel for the ultra-high-strength marine hose comprises the following steps:

[0049] Smelting, refining and continuous casting into continuous casting slabs according to the set composition, heating the slab to 1220°C for 30 minutes to homogenize the structure and composition, and then hot rolling the slab to a Φ16mm wire rod through a high-speed wire rolling mill, and the rolling temperature is 1150 ℃, final rolling temperature 970 ℃, water cooling after rolling, spinning temperature 820 ℃, slow cooling to coiling temperature 430 ℃;

[0050] The hot-rolled wire rod is cooled to room temperature, and after removing the iron scale, it undergoes 5 passes of cold rolling to obtain the flat steel require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com