High-abrasion-resistance non-woven fabric used in automobile

A non-woven fabric and needle punching machine technology, which is applied in the field of materials for car interior accessories, can solve the problems of inability to bond fibers to each other, wear resistance, poor firmness, and increase costs, so as to reduce fire phenomena, have strong firmness, and prevent The effect of spreading fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

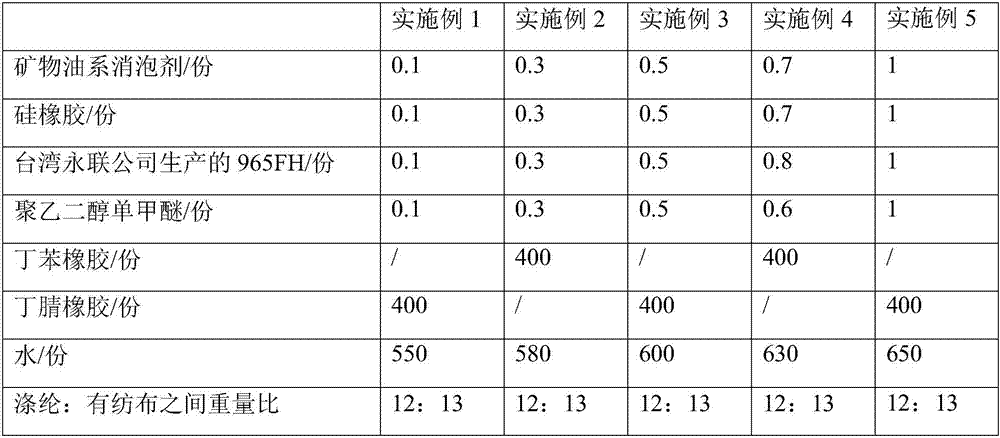

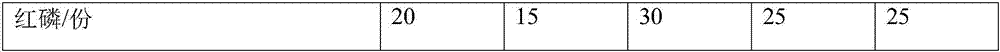

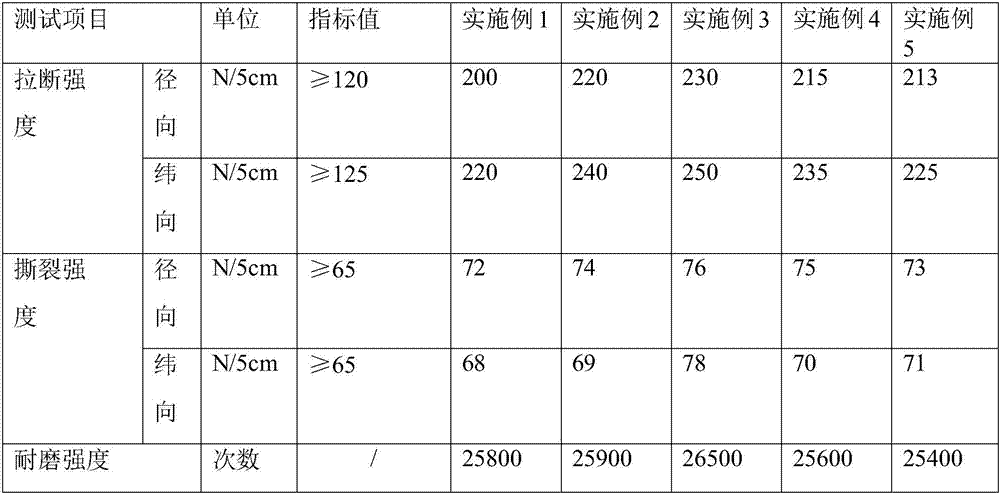

[0040] Each raw material was weighed according to the data corresponding to Example 1 in Table 1.

[0041] A highly wear-resistant non-woven fabric for the interior of a car, characterized in that it is prepared by the following method:

[0042] Step 1: The polyester is sequentially processed through a coagulator, an opener, a cotton box, a carding machine, a web forming machine, and an acupuncture machine, and woven fabric is added to the processing of the acupuncture machine, and the acupuncture machine includes Three processes of pre-punching, positive stabbing and counter-punching;

[0043] Step 2: After being processed by an acupuncture machine, it is processed by an edge cutting machine, a hot-pressing three-roller machine, and a cutter machine in sequence, and then winded by a winder to obtain a non-woven fabric;

[0044] Step 3: Set the non-woven fabric on the fabric rack for gluing, high-temperature drying, and then use an ironing machine to shape it.

Embodiment 2

[0046] Each raw material was weighed according to the data corresponding to Example 2 in Table 1.

[0047] A highly wear-resistant non-woven fabric for the interior of a car, prepared through the following steps:

[0048] The first step: the polyester is sequentially processed through a coagulator, an opener, a cotton box, a carding machine, a web forming machine, and an acupuncture machine. The acupuncture machine includes three processes of pre-punching, front-punching and back-punching The needling machine adds woven fabric during the needling process;

[0049] The second step: After the polyester is processed by the needle punching machine, it is processed by the edge cutting machine, the hot pressing three-roller machine, and the cutter machine in sequence, and then the polyester is wound into cloth by the winding machine;

[0050] Step 3: Set the rolled polyester on the cloth rack for gluing and high-temperature drying, and then use the ironing machine to process and sh...

Embodiment 3

[0052] Each raw material was weighed according to the data corresponding to Example 3 in Table 1.

[0053] A highly wear-resistant non-woven fabric for the interior of a car, prepared through the following steps:

[0054] The first step: the polyester is sequentially processed through a coagulator, an opener, a cotton box, a carding machine, a web forming machine, and an acupuncture machine. The acupuncture machine includes three processes of pre-punching, front-punching and back-punching The needling machine adds woven fabric during the needling process;

[0055]The second step: After the polyester is processed by the needle punching machine, it is processed by the edge cutting machine, the hot pressing three-roller machine, and the cutter machine in sequence, and then the polyester is wound into cloth by the winding machine;

[0056] Step 3: Set the rolled polyester on the cloth rack for gluing and high-temperature drying, and then use the ironing machine to process and sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com