Method for reducing concentration of carbon monoxide in tail gas of Ausmelt furnace

An Ausmelt furnace and carbon monoxide technology, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve the problems of large impact on the surrounding environment, endangering production safety, electric dust collection explosion, etc., to reduce the risk of potential safety hazards, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

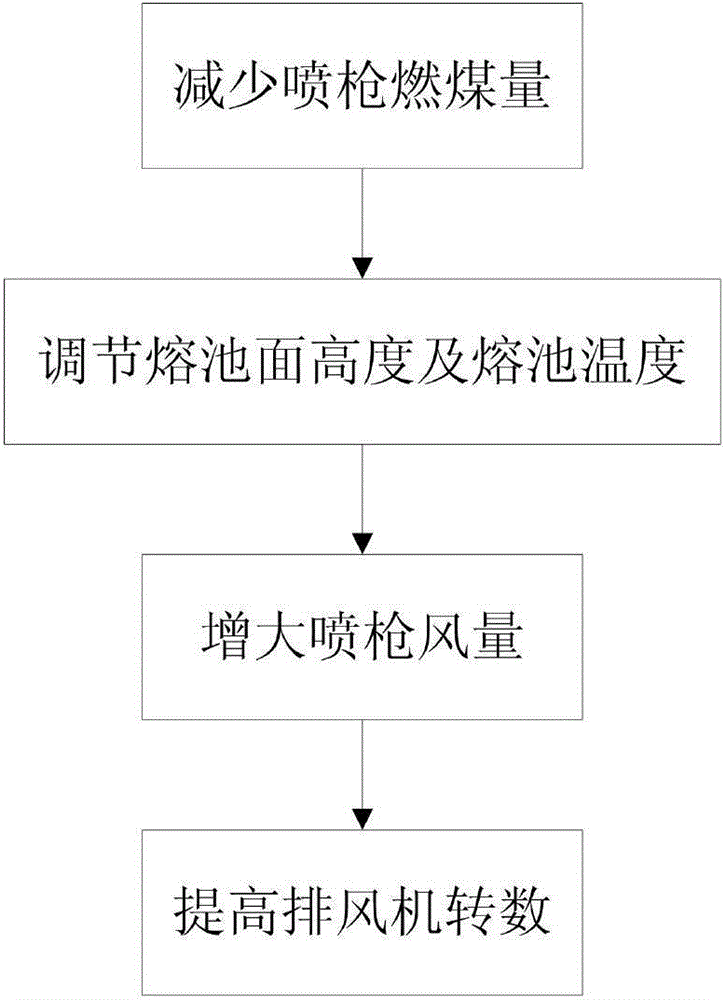

[0021] A method for reducing the concentration of carbon monoxide in the tail gas of an Ausmelt furnace, such as figure 1 shown, including the following steps,

[0022] Step 1. Measure the concentration of carbon monoxide in the tail gas of Ausmelt furnace. After the measured value of carbon monoxide concentration is higher than 3000ppm, reduce the coal consumption of the spray gun by 100kg, and reduce the coal consumption of the spray gun by 100kg every minute until the concentration of carbon monoxide in the tail gas is lower than 3000ppm , or the coal consumption of the spray gun is less than 3000kg / h;

[0023] Step 2: Keep the Ausmelt furnace continuously in production, and the surface of the molten pool is 1600mm. For every 100mm increase in the height of the molten pool, the amount of pulverized coal is increased by 50kg, and the temperature of the molten pool is increased to ensure the smooth discharge of Australian slag, and the temperature of the molten pool 1300°C; ...

Embodiment 2

[0028] A method for reducing the concentration of carbon monoxide in the tail gas of an Ausmelt furnace,

[0029] Step 1. Measure the concentration of carbon monoxide in the tail gas of Ausmelt furnace. After the measured value of carbon monoxide concentration is higher than 3000ppm, reduce the coal consumption of the spray gun by 100kg, and reduce the coal consumption of the spray gun by 100kg every minute until the concentration of carbon monoxide in the tail gas is lower than 3000ppm , or the coal consumption of the spray gun is less than 3000kg / h;

[0030] Step 2. Keep the Ausmelt furnace continuously in production, and the surface of the molten pool is 1800mm. For every 100mm increase in the height of the molten pool, the amount of pulverized coal is increased by 50kg. Increase the temperature of the molten pool to ensure the smooth discharge of Australian slag, and the temperature of the molten pool Increase to 1320°C;

[0031] Step 3. Measure the oxygen concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com