Concrete impact-resistant wearable agent composition and preparation method thereof

A wear-resistant agent and concrete technology, applied in the field of compositions, can solve problems such as loss, shortening of concrete service life, concrete damage, etc., and achieve the effects of improving workability, improving impact and wear resistance, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

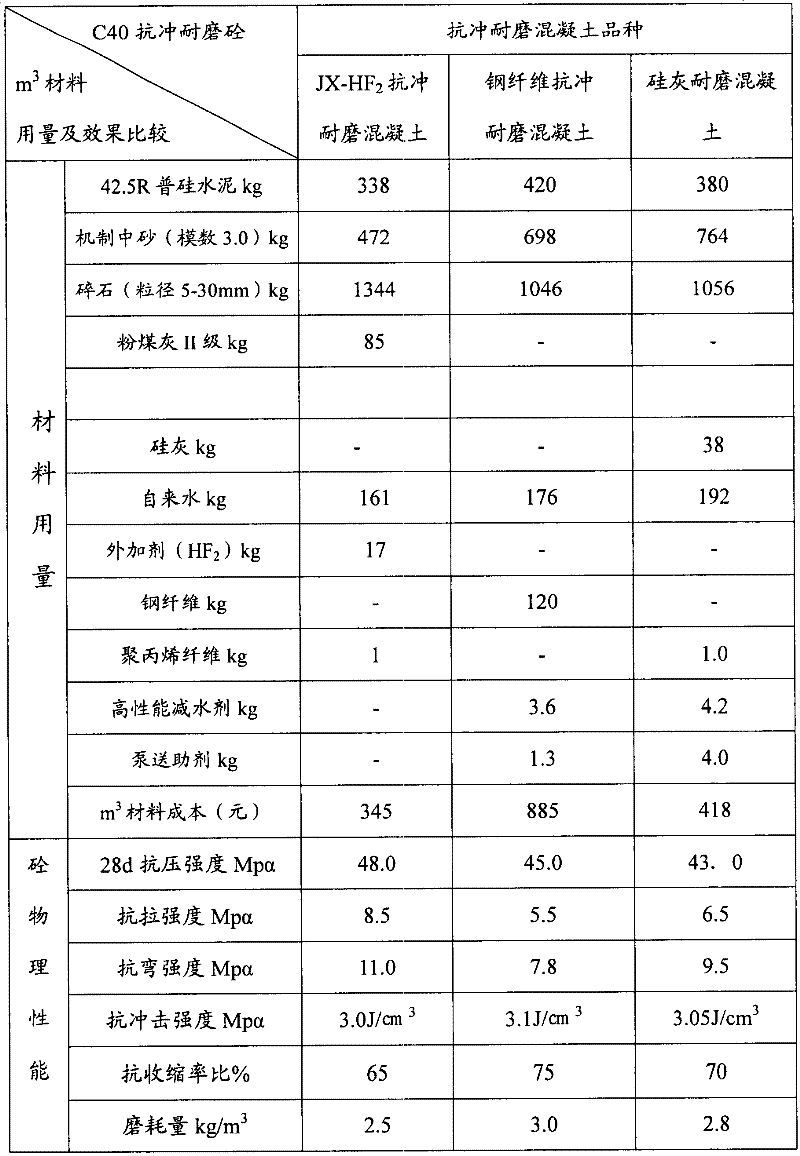

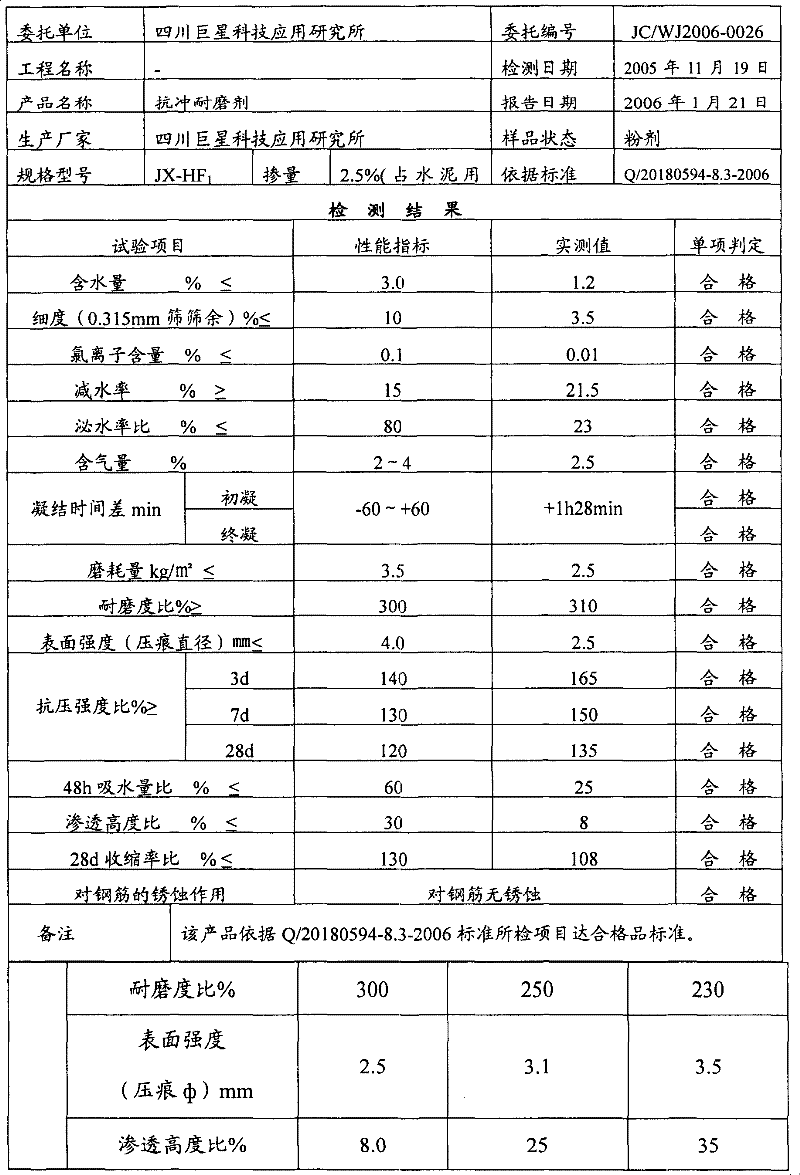

Examples

Embodiment 1

[0025] To prepare concrete anti-impact and wear-resistant agent (solid product), it is required that the concrete has excellent compactness, high flexural compressive strength, good fatigue resistance and wear resistance. The proportion of the anti-impact and anti-wear agent is (calculated by weight ratio): Sulfamate 40%, Aluminum Sulfate 25%, Triethanolamine 2.0%, Ferric Chloride 1.5%, Silicon Oxide Powder 31.5%.

Embodiment 2

[0027] Prepare the concrete anti-shock and anti-wear agent liquid product, its proportioning (by weight): 80% of polycarboxylate, 5% of triethanolamine, 5% of ferric chloride, and 10% of water.

Embodiment 3

[0029] The preparation of pumped concrete wear-resistant agent powder products should not only have the requirements of impact and wear resistance, but also have a pumping function, and will not block the pipeline when the sand rate and cementitious material are low. The ratio is (according to Calculated by weight percentage): sulfamate 30%, naphthalene sulfonate 15%, silicon oxide 21.5%, ferrous chloride 1%, triethanolamine 2.0%, air-entraining agent 0.5% (powder), retarder 3.0% (powder), calcium sulfoaluminate 25%, cellulose (hydroxyethyl) 2.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com