Composite auxiliary agent for honeycomb ceramic forming

A technology of honeycomb ceramics and composite additives, which is applied in the direction of ceramic products, applications, household appliances, etc., and can solve the problems of increased drying shrinkage and firing shrinkage of the honeycomb ceramic body, high dosage of forming aids, and density and density of honeycomb ceramic products. Low strength and other problems, to achieve the effect of improving shape retention ability, reducing the thickness of hydration film, and reducing the deformation defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

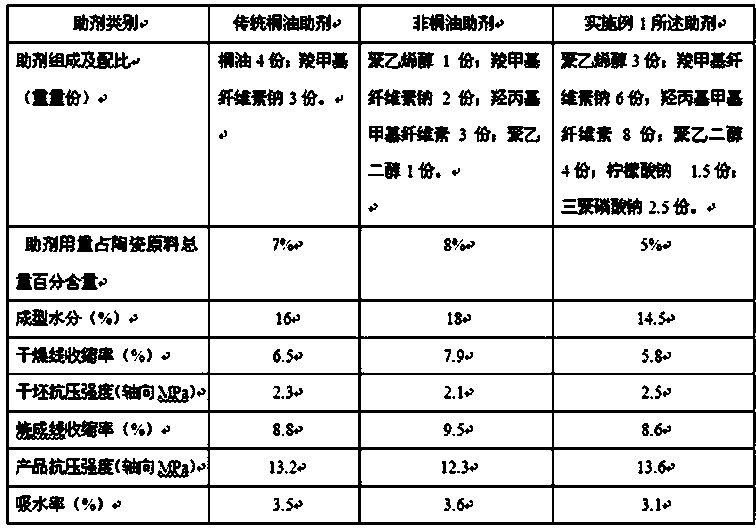

Embodiment 1

[0041] A composite auxiliary agent for forming a honeycomb ceramic regenerator, the parts by weight of each component are:

[0042] 3 parts of polyvinyl alcohol;

[0043] 6 parts of sodium carboxymethylcellulose;

[0044] 8 parts of hydroxypropyl methylcellulose;

[0045] 4 parts of polyethylene glycol;

[0046] Sodium citrate 1.5 parts;

[0047] Sodium tripolyphosphate 2.5 parts.

[0048] The specific preparation and application method of the composite auxiliary agent for forming the honeycomb ceramics are as follows:

[0049] (1) Weigh the above powdered raw materials according to the proportion, and mix them fully and evenly in the mixer to prepare the compound additive.

[0050] (2) Dry-mix the composite auxiliary agent accounting for 5% of the total weight of the honeycomb ceramic raw material dry basis with the honeycomb ceramic raw material powder to obtain a compounding material.

[0051] (3) Add 14.5% water to the batch material, and fully knead in the mud mixer...

Embodiment 2

[0061] A composite auxiliary agent for forming a honeycomb ceramic regenerator, the parts by weight of each component are:

[0062] 3 parts of polyvinyl alcohol;

[0063] 3 parts of sodium carboxymethyl cellulose;

[0064] 6 parts of hydroxypropyl methylcellulose;

[0065] 2 parts of polyethylene glycol;

[0066] 1 part sodium citrate;

[0067] Sodium tripolyphosphate 1.6 parts.

[0068] The specific preparation and application method of the composite auxiliary agent for forming the honeycomb ceramics are as follows:

[0069] (1) Weigh the above powdered raw materials according to the proportion, and mix them fully and evenly in the mixer to prepare the compound additive.

[0070] (2) Dry-mix the composite auxiliary agent accounting for 3% of the total weight of the honeycomb ceramic raw material on a dry basis with the honeycomb ceramic raw material powder to obtain a compounding material.

[0071] (3) Add 12.5% water to the batch material, and fully knead in the mud ...

Embodiment 3

[0079] A composite auxiliary agent for forming a honeycomb ceramic catalyst carrier for a chemical reaction tower, the parts by weight of each component are:

[0080] 2 parts polyvinyl alcohol;

[0081] 5 parts of sodium carboxymethyl cellulose;

[0082] 5 parts of hydroxypropyl methylcellulose;

[0083] 3 parts of polyethylene glycol;

[0084] 1 part sodium citrate;

[0085] Sodium tripolyphosphate 1.8 parts.

[0086] The specific preparation and application method of the composite auxiliary agent for forming the honeycomb ceramics are as follows:

[0087] (1) Weigh the above powdered raw materials according to the proportion, and mix them fully and evenly in the mixer to prepare the compound additive.

[0088] (2) Dry-mix the composite auxiliary agent accounting for 5% of the total weight of the honeycomb ceramic raw material dry basis with the honeycomb ceramic raw material powder to obtain a compounding material.

[0089] (3) Add 14% water to the batch material, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com