Halogen-free flame-retardant dicyclopentadiene material and preparation method thereof

A technology of polydicyclopentadiene and dicyclopentadiene, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve secondary disasters, and flame retardants cannot react with dicyclopentadiene monomer , Halogenated flame retardant use day limit and other issues, to achieve good flame retardant performance, simple and easy preparation method, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

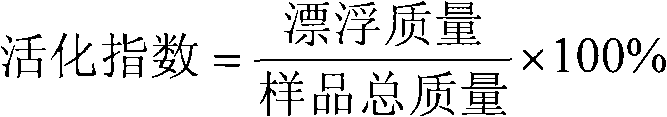

[0043] Example 1 Preparation of Modified Aluminum Hydroxide

[0044] Weigh 100 parts of aluminum hydroxide powder (particle size = 11 μm) in a beaker to prepare a suspension in 300 parts of deionized water. Stir the aluminum hydroxide suspension at a stirring speed of 1000rmp and heat to 80°C, add 2 parts of stearic acid, stir for 30min, cool down to room temperature, filter, and dry at 110°C for 10h. The modified aluminum hydroxide is obtained, and the activation index is >99.9%.

Embodiment 2-9

[0046] The test method is the same as in Example 1, and the modification results of different modifiers and different dosages are shown in Table 1.

[0047] The modification effect of different modifiers in table 1 to aluminum hydroxide

[0048]

Embodiment 10

[0050] Under nitrogen protection, 40 parts of dicyclopentadiene monomers, 30 parts of modified aluminum hydroxide obtained in Example 1, 3 parts were uniformly mixed under a high-speed mixer to obtain component A; 60 parts of dicyclopentadiene and 1.5 parts of triethylaluminum were uniformly mixed under a high-speed mixer to obtain component B; under nitrogen protection, group A and B According to the volume ratio of 1:1, it is injection molded by reaction injection molding machine, and the material properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com