A modified optical cable winding reel and its preparation method

An optical cable winding reel and modification technology, applied in the coating and other directions, can solve the problems of affecting recycling, easy breakage, poor cable protection, etc., and achieve the effect of improving weather resistance and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

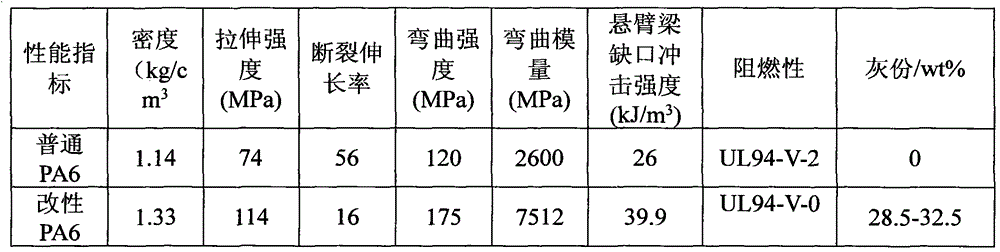

Examples

Embodiment Construction

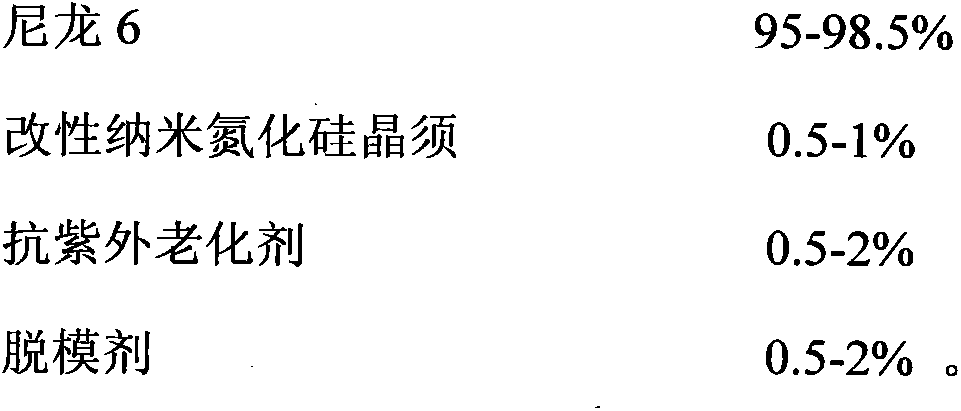

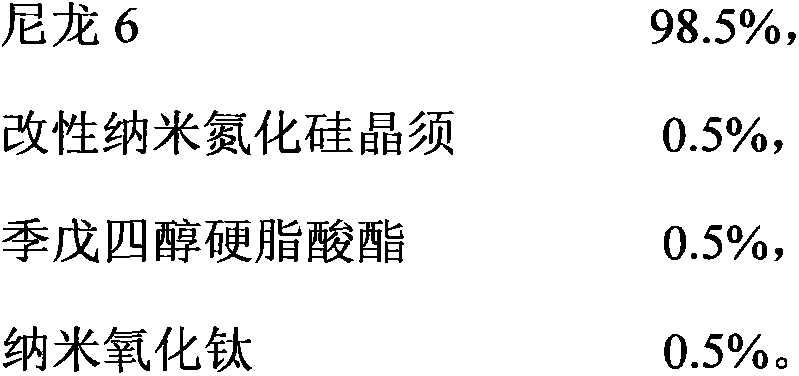

[0030] The raw material of the modified optical cable winding reel of the present invention is constituted by mass percentage:

[0031]

[0032] The preparation method is as follows:

[0033] 1. Preparation of modified nano silicon nitride whiskers:

[0034] Put 100g of nano silicon nitride whiskers into 300g of nitric acid solution with a mass concentration of 60%, react at 100°C for 36 hours, wash with distilled water to neutrality after the reaction, and dry at 100°C to obtain carboxylated nano silicon nitride ; 400g of thionyl chloride and the obtained carboxylated nano silicon nitride reacted at 80 ℃ for 36 hours, after the reaction is completed, washed with anhydrous tetrahydrofuran to neutral, 100 ℃ vacuum drying to obtain acyl chloride nano silicon nitride; The acyl chloride nano silicon nitride is mixed with octadecylamine and benzene in a mass ratio of 1:10:10, reacted at 60°C for 36 hours, washed with anhydrous tetrahydrofuran to neutrality after the reaction, and dried i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com