A kind of multifunctional foamed aluminum foaming agent and the method for using it to prepare foamed aluminum

A foam aluminum and foaming agent technology, applied in the field of foam aluminum materials, can solve the problems of foaming agent foaming ability decline, modification method complex, foaming agent floating, etc., to prolong the time of uniform dispersion and improve the utilization of raw materials rate, strong interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

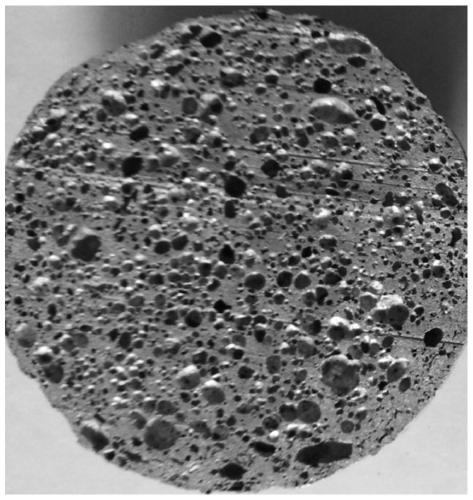

[0089] The method for preparing foamed aluminum with multifunctional foamed aluminum blowing agent described in this embodiment is as follows:

[0090] (1) Pretreatment

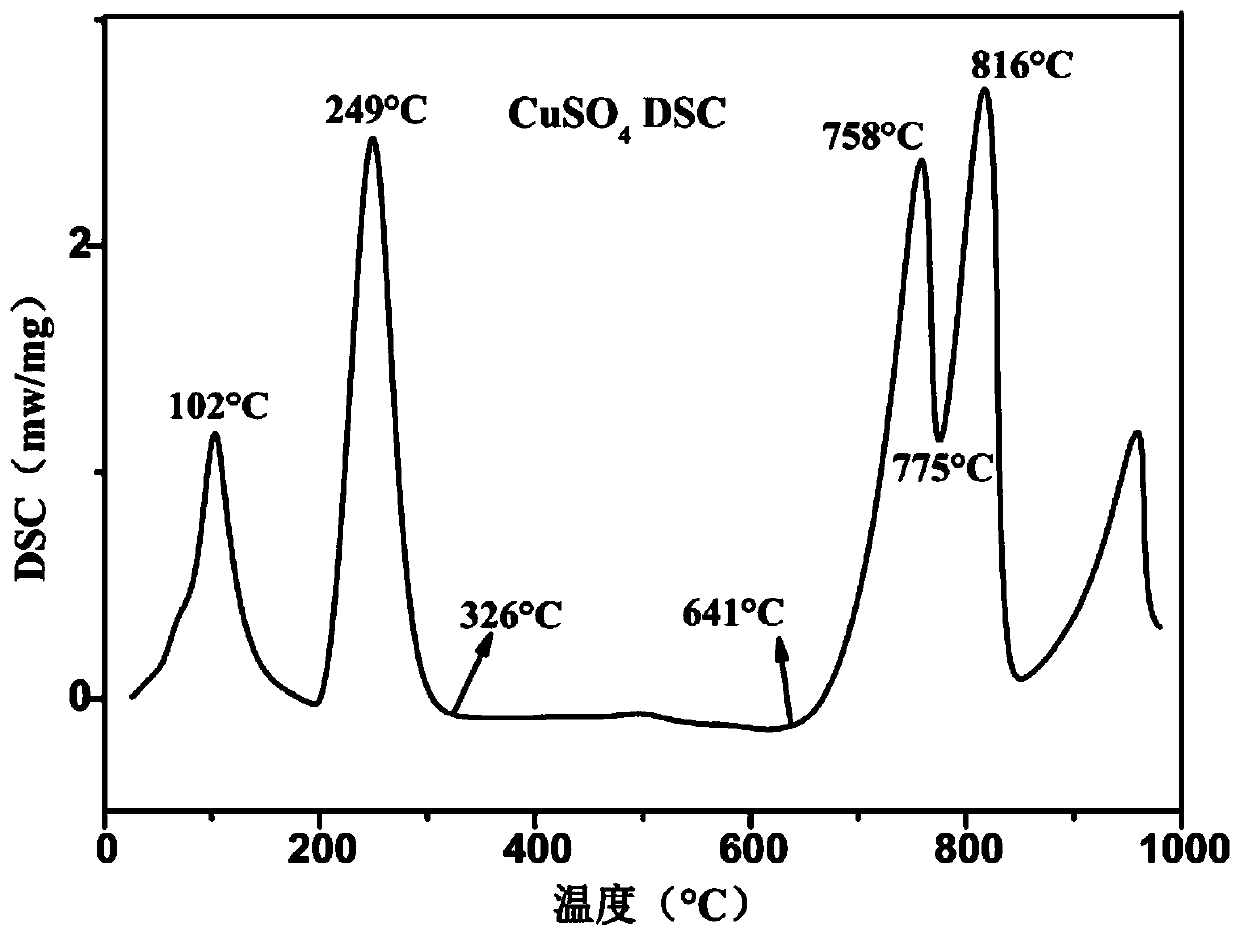

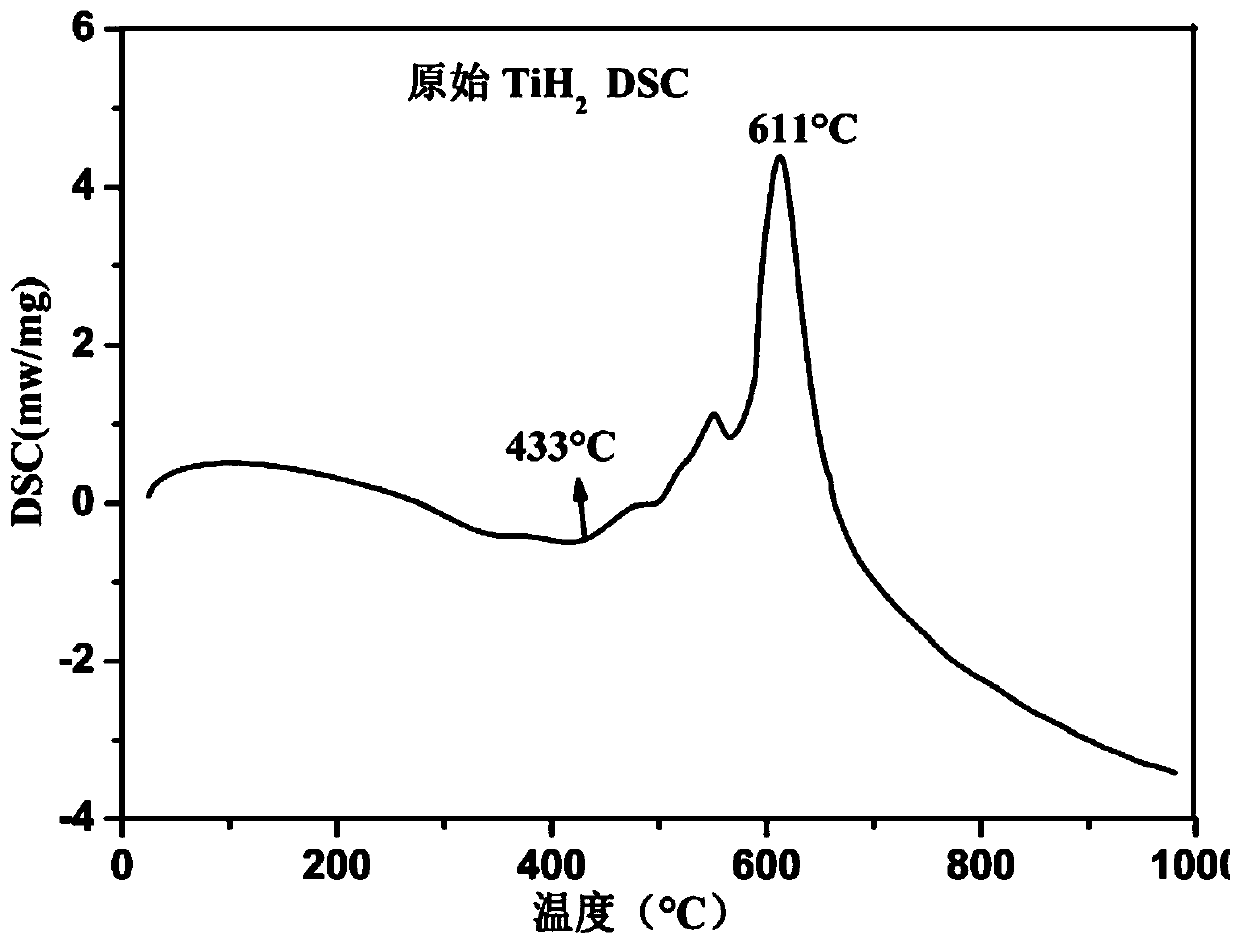

[0091] Anhydrous copper sulfate was selected as the multifunctional aluminum foam foaming agent, and anhydrous copper sulfate was heat-treated at 350°C for 3 hours to obtain dry anhydrous copper sulfate, which was stored in a drying box for later use;

[0092] (2) Ingredients

[0093] According to calcium, dry anhydrous copper sulfate quality is respectively 3%, 0.5% ratio weighing raw material of aluminum ingot quality;

[0094] (3) Melting and foaming

[0095] Put the aluminum ingot in a crucible and melt it at 660°C, then add the weighed calcium into the molten aluminum melt, stir at a stirring speed of 600r / min for 1min, and keep warm to a constant temperature of 660°C;

[0096] Remove the oxide film on the aluminum melt after heat preservation, turn on the exhaust fan, and put the air outlet of the ex...

Embodiment 2

[0100] The method for preparing foamed aluminum with multifunctional foamed aluminum blowing agent described in this embodiment is as follows:

[0101] (1) Pretreatment

[0102] Copper-containing 5H 2 O·CuSO 4 As a multi-functional aluminum foam foaming agent, heat-treat it at 400°C for 8 hours, and store it in a dry box for later use;

[0103] (2) Ingredients

[0104] Weigh the raw materials according to the ratio of alumina and multifunctional aluminum foam blowing agent to 5% and 5% of the aluminum ingot mass respectively;

[0105] (3) Melting and foaming

[0106] Put the aluminum ingot in a crucible and melt it at 700°C, then add the weighed alumina into the melted aluminum melt, stir for 5 minutes at a stirring speed of 800r / min, and keep warm to a constant temperature of 700°C;

[0107] Remove the oxide film on the aluminum melt after heat preservation, turn on the exhaust fan, and pass the air outlet of the exhaust fan into the porous activated carbon. The operator...

Embodiment 3

[0111] The method for preparing foamed aluminum with multifunctional foamed aluminum blowing agent described in this embodiment is as follows:

[0112] (1) Pretreatment

[0113] 3H containing iron impurities 2 O·CuSO 4 As a multi-functional aluminum foam foaming agent, heat-treat it at 500°C for 16 hours, and store it in a dry box for later use;

[0114] (2) Ingredients

[0115] According to TiB 2 The mass of the multi-functional aluminum foam foaming agent is 8% and 10% of the mass of the aluminum ingot, and the raw materials are weighed in proportion;

[0116] (3) Melting and foaming

[0117] Put the aluminum ingot in a crucible and melt it at 800°C, then put the weighed TiB 2 Add to the molten aluminum melt, stir for 10min at a stirring speed of 1000r / min, and keep warm to a constant temperature of 800°C;

[0118] Remove the oxide film on the aluminum melt after heat preservation, turn on the exhaust fan, and let the air outlet of the exhaust fan into the water vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com