High-elasticity anti-cracking tunnel residue shotcrete material and preparation method thereof

A sprayed concrete and high-elastic technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of stacking land occupation, inconvenient transportation, and difficult handling, so as to save resources, save costs, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

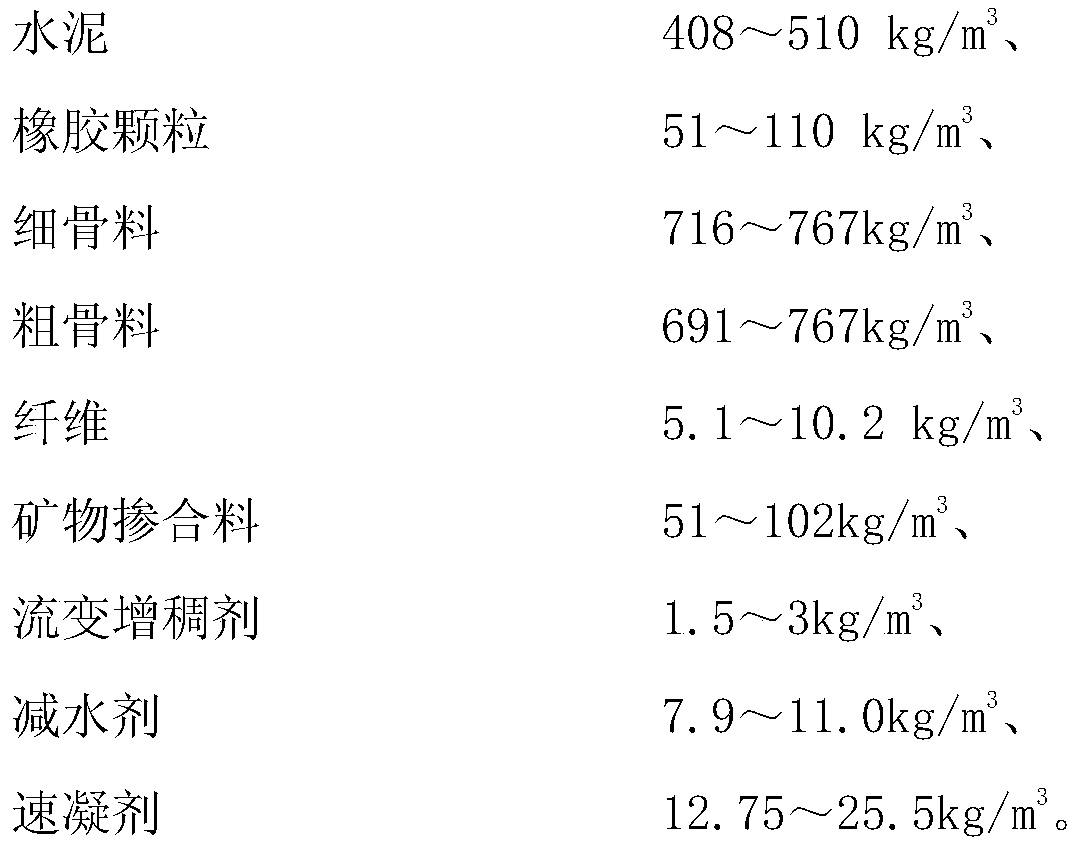

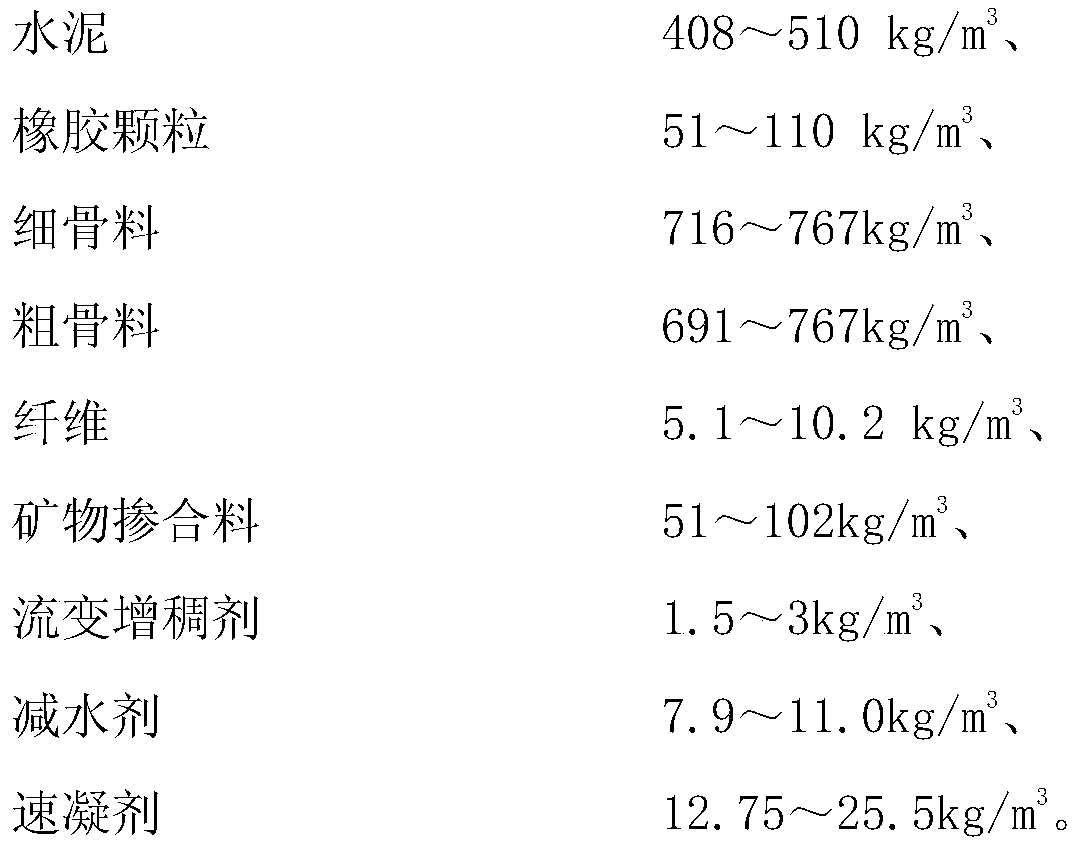

Method used

Image

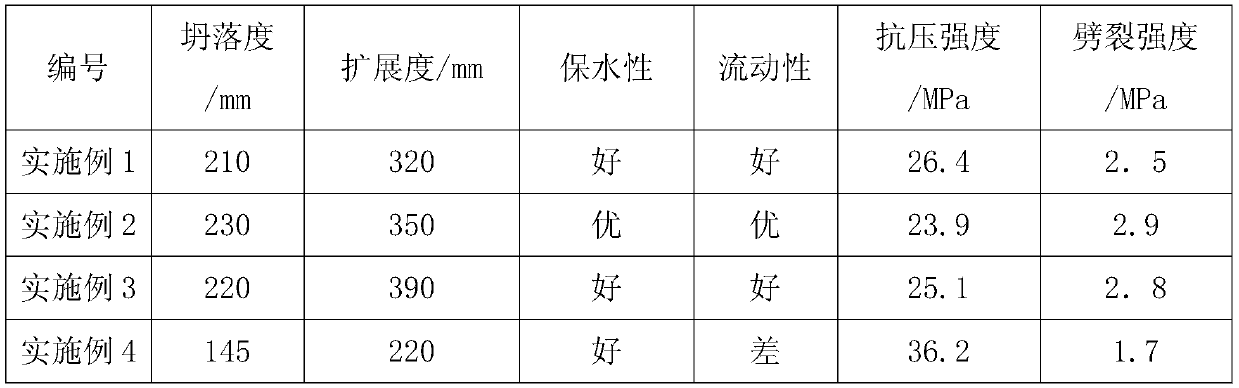

Examples

Embodiment 1

[0029] A high-elasticity-cracking slag-resistant shotcrete material, the shotcrete material includes the following components: 408kg / m 3 Portland cement (specific surface area is 300 ~ 400m 2 / kg), 51kg / m 3 rubber particles (particle size 20-100 mesh), 716kg / m 3 The fine aggregate of hole slag machine-made sand (the particle size passes through the 3mm particle size sieve), 767kg / m 3 Coarse aggregate (stones with a particle size of 5-10mm), 7.65kg / m 3 Chopped basalt fiber (length 12mm ~ 35mm), 102kg / m 3 Class I fly ash (specific surface area is 300-430m 2 / kg), 1.5kg / m 3 Carboxymethylcellulose sodium salt rheological thickener, 9.2kg / m 3 Polycarboxylate superplasticizer and 25.5kg / m 3 Alkali-free liquid accelerator.

[0030] A method for preparing a high-elasticity-cracking-resistant slag sprayed concrete material, comprising the following steps:

[0031] 1) First add the Portland cement of the formula amount into the forced mixer, then add the required rubber particl...

Embodiment 2

[0036] A high-elasticity-cracking slag-resistant shotcrete material, the shotcrete material includes the following components: 460kg / m 3 Portland cement (specific surface area is 300 ~ 400m2 / kg), 110kg / m 3 rubber particles (particle size: 20-100 mesh), 720kg / m 3 The fine aggregate of hole slag machine-made sand (the particle size passes through the 3mm particle size sieve), 725kg / m 3 Coarse aggregate (stones with a particle size of 5-10mm), 5.1kg / m 3 Chopped basalt fiber (length 12mm ~ 35mm), 102kg / m 3 The fly ash microbeads (the specific surface area is 420 ~ 450m 2 / kg), 3.0kg / m 3 Carboxymethylcellulose sodium salt rheological thickener, 11.0kg / m 3 Polycarboxylate water reducer and 12.8kg / m 3 Alkali-free liquid accelerator.

[0037] A method for preparing a high-elasticity-cracking-resistant slag sprayed concrete material, comprising the following steps:

[0038] 1) First add the Portland cement of the formula amount into the forced mixer, then add the required rubb...

Embodiment 3

[0043] A high-elasticity-cracking slag-resistant shotcrete material, the shotcrete material includes the following components: 510kg / m 3 Portland cement (specific surface area is 300 ~ 400m 2 / kg), 76.5kg / m 3 rubber particles (particle size: 20-100 mesh), 767kg / m 3 The fine aggregate of the hole slag machine-made sand (the particle size passes through the 3mm particle size sieve), 691kg / m 3 Coarse aggregate (stones with a particle size of 5-10mm), 10.2kg / m 3 Chopped basalt fiber (length 12mm ~ 35mm), 21kg / m 3 Class I fly ash (specific surface area is 300-430m 2 / kg), 30kg / m 3 The fly ash microbeads (the specific surface area is 420 ~ 450m 2 / kg), 1.5kg / m 3 Carboxymethylcellulose sodium salt rheological thickener, 7.9kg / m 3 Polycarboxylate water reducer and 15.3kg / m 3 Alkali-free liquid accelerator.

[0044] A method for preparing a high-elasticity-cracking-resistant slag sprayed concrete material, comprising the following steps:

[0045] 1) First add the Portland ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com