Inner trim board for motor car and preparing method of inner trim board

A technology for interior panels and motor vehicles, applied in non-woven fabrics, fiber types, textiles and papermaking, etc., to meet safety and functional requirements, and to absorb formaldehyde and odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

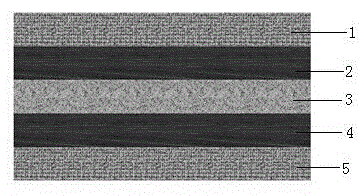

[0027] An interior trim panel for a motor vehicle, the interior trim panel for a motor vehicle is a five-layer composite structure, from top to bottom: the first nylon fiber layer, the second activated carbon fiber layer, the third kapok fiber layer, and the fourth activated carbon fiber layer layer and the fifth nylon fiber layer, the grammage of the interior trim panel for the motor vehicle is 1000g / m 2 , the first nylon fiber layer accounts for 25% of the total weight ratio, the second activated carbon fiber layer accounts for 10% of the total weight ratio, the third kapok fiber layer accounts for 20% of the total weight ratio, and the fourth activated carbon fiber layer accounts for 20% of the total weight ratio. The ratio is 10%, and the fifth nylon fiber layer accounts for 25% of the total weight ratio.

[0028] As an optimization: the motor car interior trim panel includes: 50 parts of nylon fiber, 20 parts of activated carbon fiber, 20 parts of kapok fiber, 10 parts of...

Embodiment 2

[0039] An interior trim panel for a motor vehicle, the interior trim panel for a motor vehicle is a five-layer composite structure, from top to bottom: the first nylon fiber layer, the second activated carbon fiber layer, the third kapok fiber layer, and the fourth activated carbon fiber layer layer and the fifth nylon fiber layer, the grammage of the interior trim panel for the motor vehicle is 3000 g / m 2 , the first nylon fiber layer accounts for 38% of the total weight ratio, the second activated carbon fiber layer accounts for 5% of the total weight ratio, the third kapok fiber layer accounts for 10% of the total weight ratio, and the fourth activated carbon fiber layer accounts for 10% of the total weight ratio. The ratio is 5%, and the fifth nylon fiber layer accounts for 38% of the total weight ratio.

[0040] As optimization: the motor car interior trim panel includes: 76 parts of nylon fiber, 10 parts of activated carbon fiber, 10 parts of kapok fiber, 4 parts of flam...

Embodiment 3

[0051] An interior trim panel for a motor vehicle, the interior trim panel for a motor vehicle is a five-layer composite structure, from top to bottom: the first nylon fiber layer, the second activated carbon fiber layer, the third kapok fiber layer, and the fourth activated carbon fiber layer layer and the fifth nylon fiber layer, the grammage of the interior trim panel for the motor vehicle is 2000 g / m 2, the first nylon fiber layer accounts for 31% of the total weight ratio, the second activated carbon fiber layer accounts for 8% of the total weight ratio, the third kapok fiber layer accounts for 16% of the total weight ratio, and the fourth activated carbon fiber layer accounts for the total weight ratio The ratio is 8%, and the fifth nylon fiber layer accounts for 31% of the total weight ratio.

[0052] The interior trim board for motor vehicles includes: 62 parts of nylon fiber, 16 parts of activated carbon fiber, 16 parts of kapok fiber, and 6 parts of flame retardant s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com