Flame-retardant activated carbon fabric and preparation method thereof

The technology of activated carbon cloth and activated carbon layer is applied in the field of flame retardant composite materials and its preparation, which can solve the problems of easily polluting the environment, easily dropping powder particles, affecting product application, etc., achieving good flame retardant performance, simple and convenient use, and preventing mildew. breeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

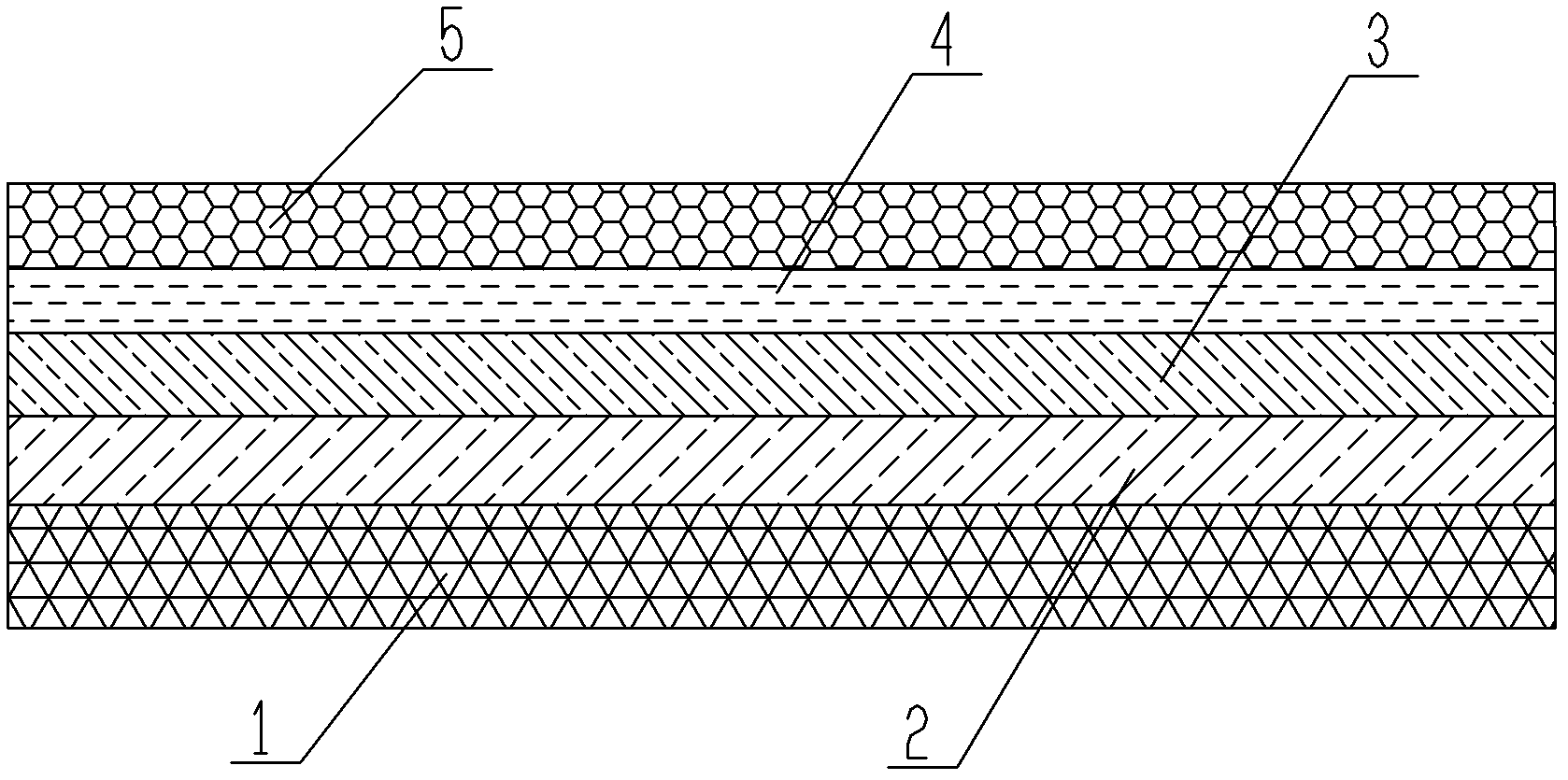

Image

Examples

Embodiment 1

[0045] Prepare flame-retardant activated carbon cloth as follows:

[0046] (1) Substrate pretreatment: use an environmentally friendly water-based flame retardant at an area density of 80g / m 2 Spray glue or pad dry on the spunlace non-woven fabric substrate, pretreat the substrate, and obtain a flame-retardant pretreated substrate;

[0047] (2) Preparation of carbon slurry: 60kg of deionized water, particle size of 200-400 mesh, iodine adsorption value of 1150mg / g, specific surface area of 1180m 2 After mixing and stirring 15 kg of conductive active bamboo charcoal powder per gram, add 2 kg of water-soluble non-film-forming adhesive, 2 kg of acrylic water-absorbing resin, and 20 kg of modified water-based vinegar-acrylic emulsion in sequence, mix and stir to make the bamboo charcoal powder disperse evenly, and then add dispersing flow Agent 1kg, mixed and stirred, made 100kg activated carbon slurry;

[0048] (3) Preparation of hot-melt adhesive powder slurry: 2.5kg of modi...

Embodiment 2

[0051] Prepare flame-retardant activated carbon cloth as follows:

[0052] (1) Substrate pretreatment: use an environmentally friendly water-based flame retardant at an area density of 150g / m 2 Spray glue or pad dry on the spunlace non-woven fabric substrate, pretreat the substrate, and obtain a flame-retardant pretreated substrate;

[0053] (2) Preparation of carbon slurry: 48kg of deionized water, particle size of 300-500 mesh, iodine adsorption value of 1180mg / g, specific surface area of 1200m 2 After mixing and stirring 20kg of conductive active bamboo charcoal powder per gram, add 10kg of water-soluble non-film-forming adhesive, 10kg of acrylic water-absorbing resin, and 2kg of modified water-based vinegar-acrylic emulsion in sequence, mix and stir to make the bamboo charcoal powder disperse evenly, and then add the dispersed flow Agent 10kg, mixed and stirred, made 100kg activated carbon slurry;

[0054] (3) Preparation of hot melt adhesive powder slurry: 10 kg of mo...

Embodiment 3

[0057] Prepare flame-retardant activated carbon cloth as follows:

[0058] (1) Substrate pretreatment: use an environmentally friendly water-based flame retardant at an area density of 100g / m 2 Spray glue or pad dry on the needle-punched non-woven fabric substrate, pretreat the substrate, and obtain a flame-retardant pretreated substrate;

[0059] (2) Preparation of carbon slurry: 33.5kg of deionized water, particle size of 400-600 mesh, iodine adsorption value of 1120mg / g, specific surface area of 1150m 2 After mixing and stirring 45kg of wood activated carbon powder per gram, add 6kg of water-soluble non-film-forming adhesive, 5kg of acrylic water-absorbing resin, and 5kg of modified water-based vinegar-acrylic emulsion in turn, mix and stir to make the bamboo charcoal powder disperse evenly, and then add a dispersing flow agent 5.5kg, mixed and stirred to make 100kg activated carbon slurry;

[0060] (3) Preparation of hot melt adhesive powder slurry: 6 kg of modified wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com